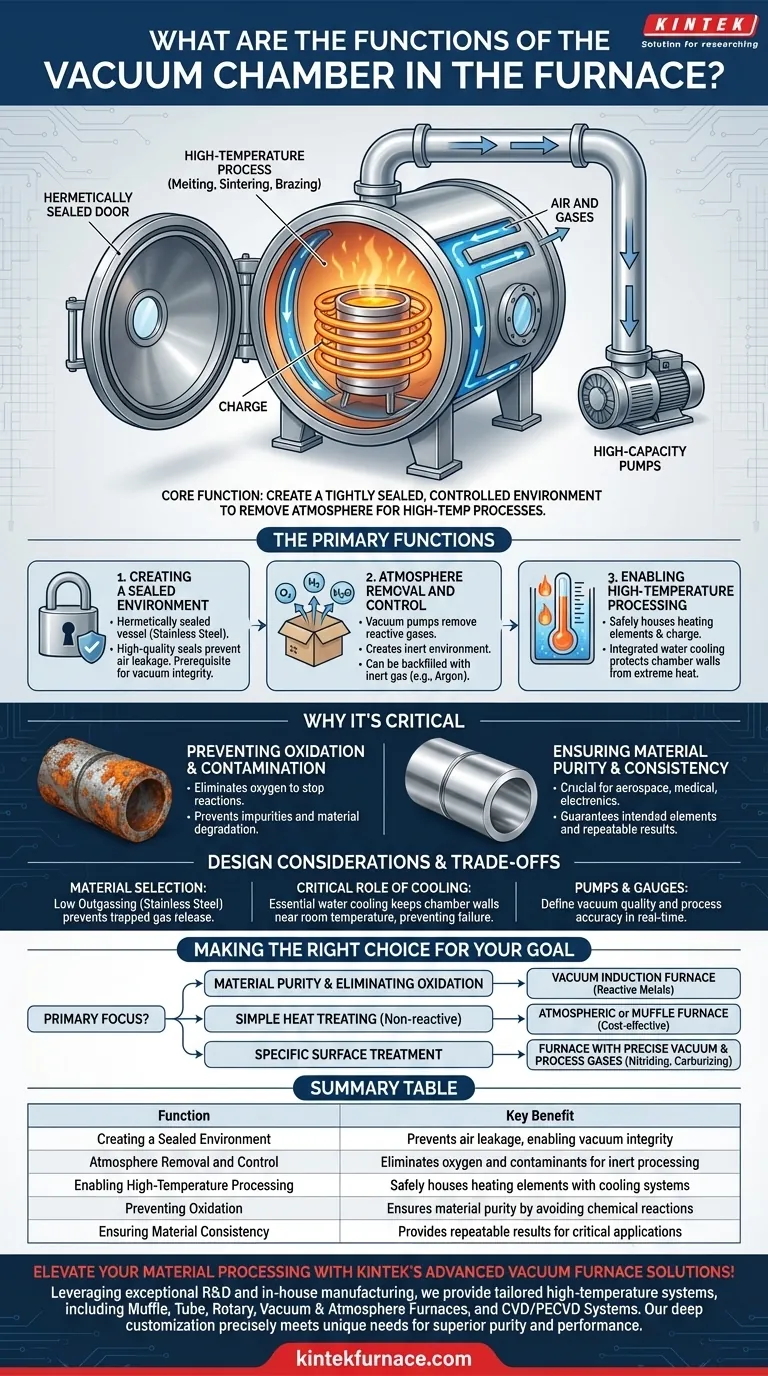

At its core, a vacuum chamber in a furnace is much more than a simple container. Its primary function is to create a tightly sealed environment where the atmosphere can be completely removed and precisely controlled. This allows high-temperature processes like melting, sintering, or brazing to occur without the undesirable chemical reactions, such as oxidation, that would happen in open air.

The fundamental role of the vacuum chamber is to eliminate atmospheric variables from a high-temperature process. By removing reactive gases like oxygen, it ensures the chemical purity, structural integrity, and overall quality of the material being processed.

The Primary Functions: Beyond Simple Containment

The chamber's design is dictated by three critical operational requirements that work in concert.

Creating a Sealed Environment

A vacuum furnace chamber is engineered to be a hermetically sealed vessel. It is typically constructed from durable materials like stainless steel with high-quality seals on all openings, such as the main access door and ports for instrumentation.

This perfect seal is the prerequisite for all other functions, as it prevents any air from leaking back into the system after the vacuum has been created.

Atmosphere Removal and Control

Once sealed, high-capacity pumps are used to evacuate the air and other gases from the chamber, creating a vacuum. This step is crucial for removing oxygen, nitrogen, and water vapor.

By eliminating these reactive elements, the chamber creates an inert environment. In some processes, after a vacuum is achieved, the chamber may be backfilled with a specific, non-reactive gas like argon to provide a controlled, inert atmosphere at a desired pressure.

Enabling High-Temperature Processing

The chamber safely houses the essential components of the furnace, including the charge (the material being heated), the crucible that holds it, and the heating element, often an induction coil.

While the interior can reach thousands of degrees, the chamber walls themselves are not designed to withstand that heat directly. They almost always incorporate integrated cooling channels through which a fluid, usually water, circulates to protect the chamber's structure, seals, and external instrumentation.

Why a Vacuum Environment is So Critical

Removing the atmosphere is not just a procedural step; it is the central principle that enables the production of high-performance materials.

Preventing Oxidation and Contamination

At high temperatures, most metals and many materials react aggressively with oxygen. This reaction, known as oxidation, can form impurities, degrade the material's properties, and lead to product failure.

A vacuum environment effectively eliminates the oxygen available for these reactions, preventing contamination and ensuring the material remains in its pure form.

Ensuring Material Purity and Consistency

For industries like aerospace, medical implants, and electronics, material purity is non-negotiable. A vacuum furnace guarantees that the only elements present in the final product are the ones intended.

This level of control ensures high-quality, consistent results from one batch to the next, which is essential for materials with critical performance specifications.

Understanding the Trade-offs and Design

The effectiveness of a vacuum furnace is directly tied to the engineering of its chamber and supporting systems.

Material Selection: Low Outgassing

Chambers are often made of stainless steel not just for its strength, but for its low outgassing properties. This means the material itself does not release trapped gases when placed under vacuum, which would otherwise contaminate the environment you are trying to clean.

The Critical Role of Cooling

A common misconception is that the chamber itself gets hot. In reality, a robust cooling system is essential to keep the chamber walls at or near room temperature. Failure of the cooling system would lead to rapid overheating, compromising the seals and potentially causing catastrophic failure of the chamber.

Pumps and Gauges Define Performance

The chamber is only as good as its supporting equipment. The quality of the vacuum is determined by the pump system's ability to remove air, and the accuracy of the process is dependent on pressure gauges that monitor the vacuum level in real-time.

Making the Right Choice for Your Goal

Understanding the function of the vacuum chamber helps you select the right tool for your specific material processing objective.

- If your primary focus is material purity and eliminating oxidation: A vacuum induction furnace is essential for melting or treating reactive metals like titanium or superalloys.

- If your primary focus is simple heat treating of non-reactive materials: A standard atmospheric furnace or a muffle furnace may be a sufficient and more cost-effective choice.

- If your primary focus is a specific surface treatment: You need a furnace with precise vacuum capabilities and the ability to introduce specific process gases, such as for nitriding or carburizing.

Ultimately, mastering the environment within the chamber is the key to mastering the final properties of your material.

Summary Table:

| Function | Key Benefit |

|---|---|

| Creating a Sealed Environment | Prevents air leakage, enabling vacuum integrity |

| Atmosphere Removal and Control | Eliminates oxygen and contaminants for inert processing |

| Enabling High-Temperature Processing | Safely houses heating elements with cooling systems |

| Preventing Oxidation | Ensures material purity by avoiding chemical reactions |

| Ensuring Material Consistency | Provides repeatable results for critical applications |

Elevate your material processing with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior purity and performance. Contact us today to discuss how we can optimize your processes and deliver reliable results!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis