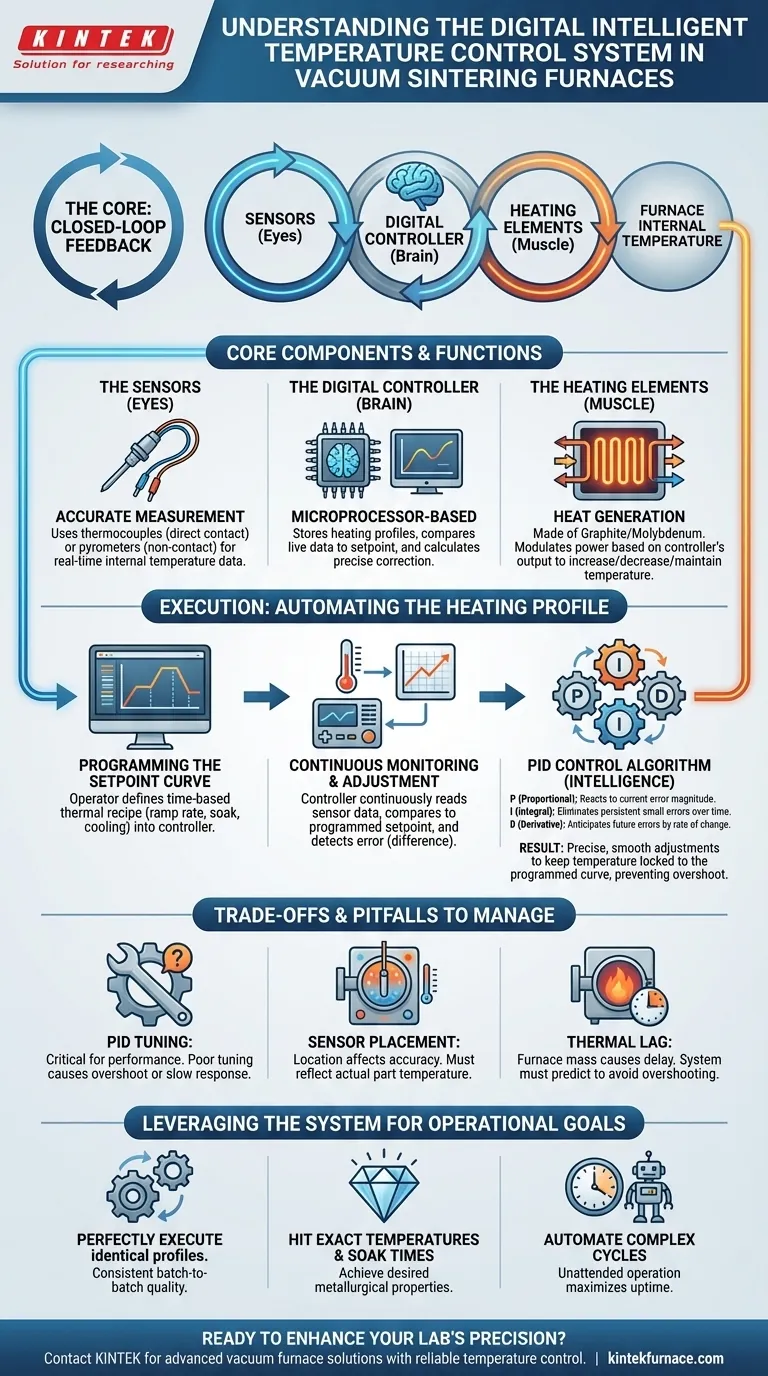

At its core, an intelligent temperature control system in a vacuum sintering furnace operates as a closed-loop feedback system. It uses sensors like thermocouples to continuously measure the furnace's internal temperature, which a digital controller then compares to a pre-programmed heating profile. Based on any deviation, the controller precisely adjusts the power sent to the heating elements to ensure the actual temperature flawlessly follows the desired curve.

The system’s "intelligence" is not just about maintaining a set temperature; it is about automating a complex, time-based thermal recipe. This guarantees that every stage of the sintering process—from initial heating to final cooling—is executed with high precision and repeatability, which is fundamental to achieving desired material properties.

The Core Components of an Intelligent Control System

To understand how the system works, it's best to break it down into its three functional parts: the sensors, the controller, and the heating elements. Each plays a distinct role in achieving precise thermal management.

The Sensors: The System's "Eyes"

The entire control process begins with an accurate measurement. The system relies on highly sensitive instruments to report the real-time temperature inside the furnace.

The most common sensors are thermocouples, which are robust and reliable for direct contact measurement. In some high-temperature applications, non-contact pyrometers may also be used to measure the thermal radiation from the material's surface.

The Digital Controller: The System's "Brain"

This is where the "intelligent" part of the system resides. The controller is a microprocessor-based device that performs several critical tasks.

First, it stores the desired heating profile, which is the multi-stage temperature curve (e.g., ramp rate, soak time, cooling rate) required for the specific material being sintered. Modern controllers can store dozens of these profiles.

Second, it continuously compares the live temperature data from the sensors to the programmed setpoint for that exact moment in the cycle. It then calculates the necessary correction.

The Heating Elements: The System's "Muscle"

The heating elements, typically made of graphite or molybdenum, are the components that generate the heat. They receive power as directed by the controller.

The controller doesn't just turn them on or off. It uses sophisticated outputs to modulate the power, delivering just enough energy to either increase, decrease, or maintain the temperature according to the profile's demands.

How the System Executes a Heating Profile

These components work in a continuous, closed loop to automate the entire sintering process. This ensures that the material experiences the exact thermal treatment it requires.

Programming the Setpoint Curve

Before a cycle begins, an operator programs the desired heating recipe into the controller. This "temperature rise curve" dictates the target temperature for every second of the process, ensuring a controlled, predictable environment.

Continuous Monitoring and Adjustment

Once the cycle starts, the controller begins its loop. It reads the thermocouple data, compares it to the programmed setpoint, and identifies any difference, or error.

For example, if the furnace is at 500°C but the program requires it to be at 502°C, the controller detects a -2°C error and calculates the need for more power.

The PID Control Algorithm

The intelligence lies in how the controller calculates the correction. Most systems use a PID (Proportional-Integral-Derivative) algorithm.

- Proportional gain reacts to the current error. A larger error results in a larger power adjustment.

- Integral gain looks at past errors. It ramps up the response if the error persists, eliminating small but steady deviations.

- Derivative gain anticipates future errors by looking at the rate of temperature change. This helps prevent overshooting the target temperature.

This PID logic allows the controller to make rapid, smooth adjustments that keep the furnace temperature tightly locked to the programmed curve, preventing the oscillations or overshoots common in simpler control systems.

Understanding the Trade-offs and Pitfalls

While highly effective, the performance of an intelligent control system depends on its setup and the physical limitations of the furnace itself.

The Importance of PID Tuning

A PID controller is only as good as its tuning. A poorly tuned system can cause the temperature to overshoot the setpoint, oscillate wildly, or respond too slowly. Proper tuning is essential for matching the controller's logic to the furnace's specific thermal characteristics.

Sensor Placement and Accuracy

The system's control is based entirely on the temperature at the sensor's location. If the sensor is placed in a hot or cold spot within the furnace, the control will be accurate for that spot but may not reflect the temperature of the actual parts, leading to non-uniform sintering.

Thermal Lag and Inertia

A furnace has thermal mass; it cannot heat up or cool down instantly. The control system must be intelligent enough to account for this lag, starting or stopping the power delivery before the setpoint is reached to avoid overshooting. This predictive capability is a key function of the derivative component in PID control.

Making the Right Choice for Your Goal

Understanding how this system works allows you to leverage it for specific operational outcomes.

- If your primary focus is process repeatability: Leverage the system's ability to store and perfectly execute identical heating profiles, eliminating operator variability and ensuring consistent batch-to-batch quality.

- If your primary focus is material quality: Rely on the PID controller's precision to hit the exact temperatures and soak times needed to achieve specific metallurgical phases and part density, avoiding defects.

- If your primary focus is operational efficiency: Use the system's automation to run complex, multi-stage cycles unattended, freeing up personnel and maximizing furnace uptime.

Ultimately, this intelligent system transforms the furnace from a simple oven into a precise instrument for materials science.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Sensors | Measure temperature | Uses thermocouples or pyrometers for real-time data |

| Digital Controller | Processes data and adjusts power | Implements PID algorithms for error correction |

| Heating Elements | Generate heat | Made of graphite or molybdenum, modulated by controller |

Ready to enhance your lab's precision and efficiency? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need reliable temperature control for repeatable sintering or tailored setups for complex thermal processes, we can help. Contact us today to discuss how our solutions can benefit your specific goals!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes