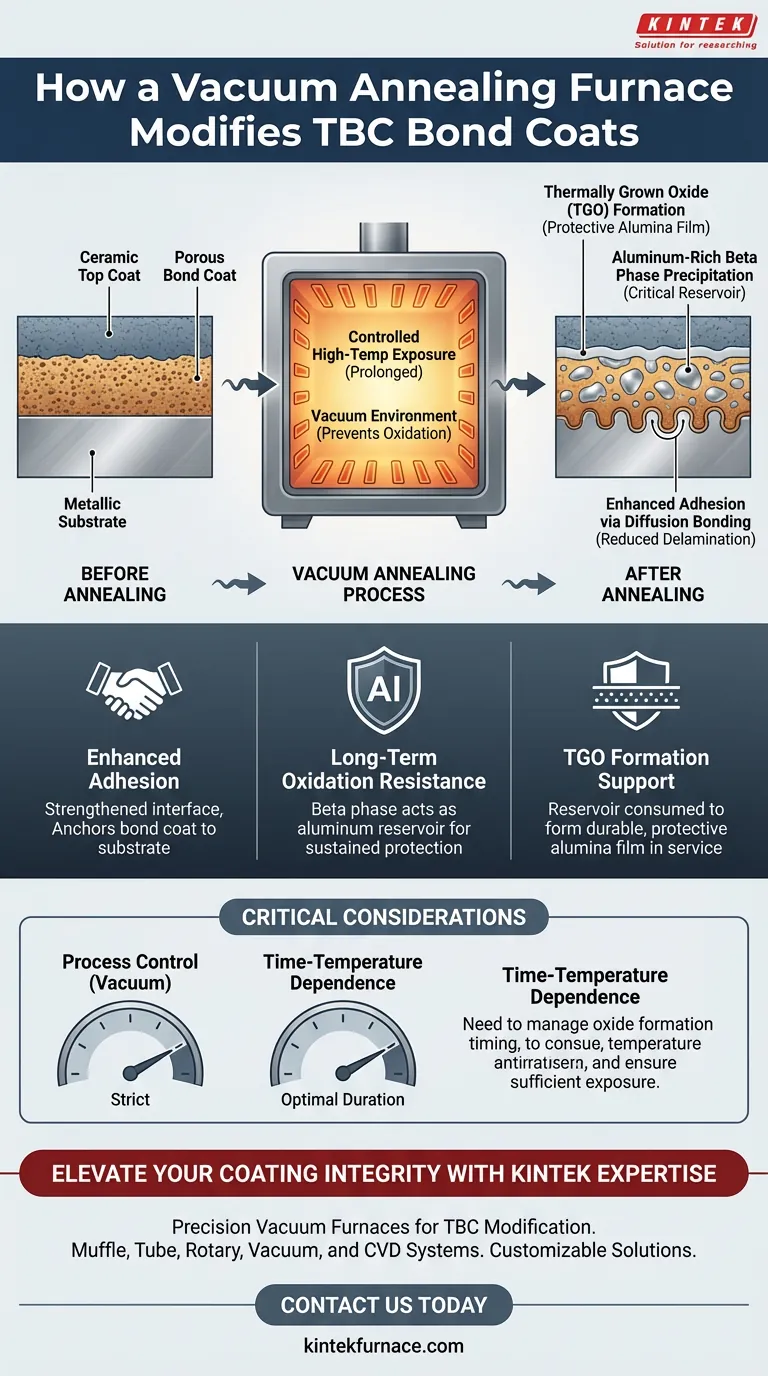

A vacuum annealing furnace modifies the bond coat by subjecting the Thermal Barrier Coating (TBC) system to prolonged heat treatment within a controlled vacuum environment. This process fundamentally alters the coating’s microstructure to enhance adhesion and prepare the system for long-term oxidation resistance.

The primary function of vacuum annealing is to induce the precipitation of an aluminum-rich beta phase within the bond coat. This phase acts as a critical reservoir for forming the Thermally Grown Oxide (TGO), which protects the component during service, while simultaneously enhancing the bond through diffusion.

The Mechanism of Modification

Controlled High-Temperature Exposure

The furnace performs these modifications through prolonged heat treatment. This is not a rapid thermal cycle, but a sustained process designed to drive chemical and structural changes deep within the coating.

The Necessity of a Vacuum Environment

The modification takes place in a high-temperature vacuum. This controlled atmosphere is essential to facilitate the necessary microstructural evolution without introducing contaminants or causing uncontrolled oxidation before the system enters service.

Structural and Chemical Changes

Promoting Diffusion Bonding

One of the immediate physical impacts of the process is the enhancement of the interface between layers. The heat treatment promotes diffusion bonding.

This occurs specifically between the substrate (the base metal) and the bond coat. By facilitating atomic diffusion, the furnace effectively anchors the bond coat to the substrate, reducing the risk of delamination.

Precipitation of the Beta Phase

The most critical chemical modification occurs within the bond coat itself. The annealing process induces the precipitation of aluminum.

This results in the formation of an aluminum-rich beta phase. This specific microstructural phase is the defining characteristic of a properly annealed bond coat.

The Purpose: Preparing for Service

Creating an Aluminum Reservoir

The beta phase formed during annealing is not merely a structural byproduct; it is a functional requirement. It serves as a stored "reservoir" of aluminum.

Forming the Thermally Grown Oxide (TGO)

This reservoir is utilized when the component is eventually put into service. The stored aluminum is consumed to form a dense, protective alumina film.

This film is known as Thermally Grown Oxide (TGO). The pre-service annealing ensures that the bond coat has the necessary chemical composition to sustain this protective layer over time.

Critical Considerations

The Importance of Process Control

While the goal is to create an oxide layer eventually, the annealing process itself requires a vacuum to manage when that oxide forms.

The environment must be strictly controlled to ensure that the aluminum precipitates into the beta phase reservoir rather than oxidizing prematurely during the manufacturing stage.

Time-Temperature Dependence

The quality of the bond coat modification is directly tied to the duration of exposure.

Because the process relies on diffusion and precipitation—both time-dependent mechanisms—insufficient heat treatment will fail to establish the robust beta phase required for long-term protection.

Making the Right Choice for Your Goal

Vacuum annealing is not just a finishing step; it is a synthesis step that activates the protective properties of the TBC system.

- If your primary focus is mechanical adhesion: Ensure the annealing profile allows sufficient time for diffusion bonding to secure the bond coat to the substrate.

- If your primary focus is long-term oxidation resistance: Verify that the process parameters have successfully maximized the precipitation of the aluminum-rich beta phase to support TGO formation.

Ultimately, the vacuum annealing furnace transforms the bond coat from a simple applied layer into a chemically active reservoir capable of sustaining high-temperature protection.

Summary Table:

| Process Mechanism | Physical/Chemical Change | Functional Outcome |

|---|---|---|

| High-Temp Vacuum Treatment | Sustained heat in controlled atmosphere | Prevents premature oxidation & contamination |

| Diffusion Bonding | Atomic migration at the substrate interface | Strengthened adhesion & reduced delamination |

| Beta Phase Precipitation | Formation of aluminum-rich reservoirs | Long-term source for protective TGO formation |

| Structural Evolution | Microstructural stabilization | Enhanced oxidation resistance during service |

Elevate Your Coating Integrity with KINTEK Expertise

Precision is non-negotiable when modifying critical Thermal Barrier Coating (TBC) systems. At KINTEK, we understand that the perfect bond coat requires rigorous process control and high-performance thermal environments.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet your unique metallurgical needs. Whether you are optimizing diffusion bonding or maximizing aluminum-rich beta phase precipitation, our advanced vacuum technology ensures your components are service-ready.

Ready to achieve superior heat treatment results? Contact us today to consult with our specialists and find the ideal furnace solution for your laboratory or production line.

Visual Guide

References

- Jens Igel, Robert Vaßen. Extended Lifetime of Dual-Layer Yttria-Stabilized Zirconia APS/Gadolinium Zirconate SPS Thermal Barrier Coatings in Furnace Cycle Tests. DOI: 10.3390/coatings14121566

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the core function of a vacuum distillation furnace in high-hazard waste magnesium recovery processes? Purify and Recycle Valuable Metal Safely

- What are the advantages of using high-pressure autoclaves for HTL? Boost Energy Efficiency with Wet Biomass Processing

- What are the key steps in the operation of a vacuum chamber? Master the Process for Precision Control

- What is the contamination risk in low vacuum versus high vacuum furnaces? Balance Purity, Cost, and Throughput

- How does an annealing furnace achieve uniform temperature distribution? Master Heat Treatment Consistency

- How does a vacuum furnace improve smelting quality? Achieve Purer, Stronger Metals for Your Applications

- What is the structure of the heating chamber in a vacuum furnace? Optimize Heat Treatment with Precision Design

- How are vacuum annealing furnaces used in solar cell manufacturing? Boost Efficiency with Precision Heat Treatment