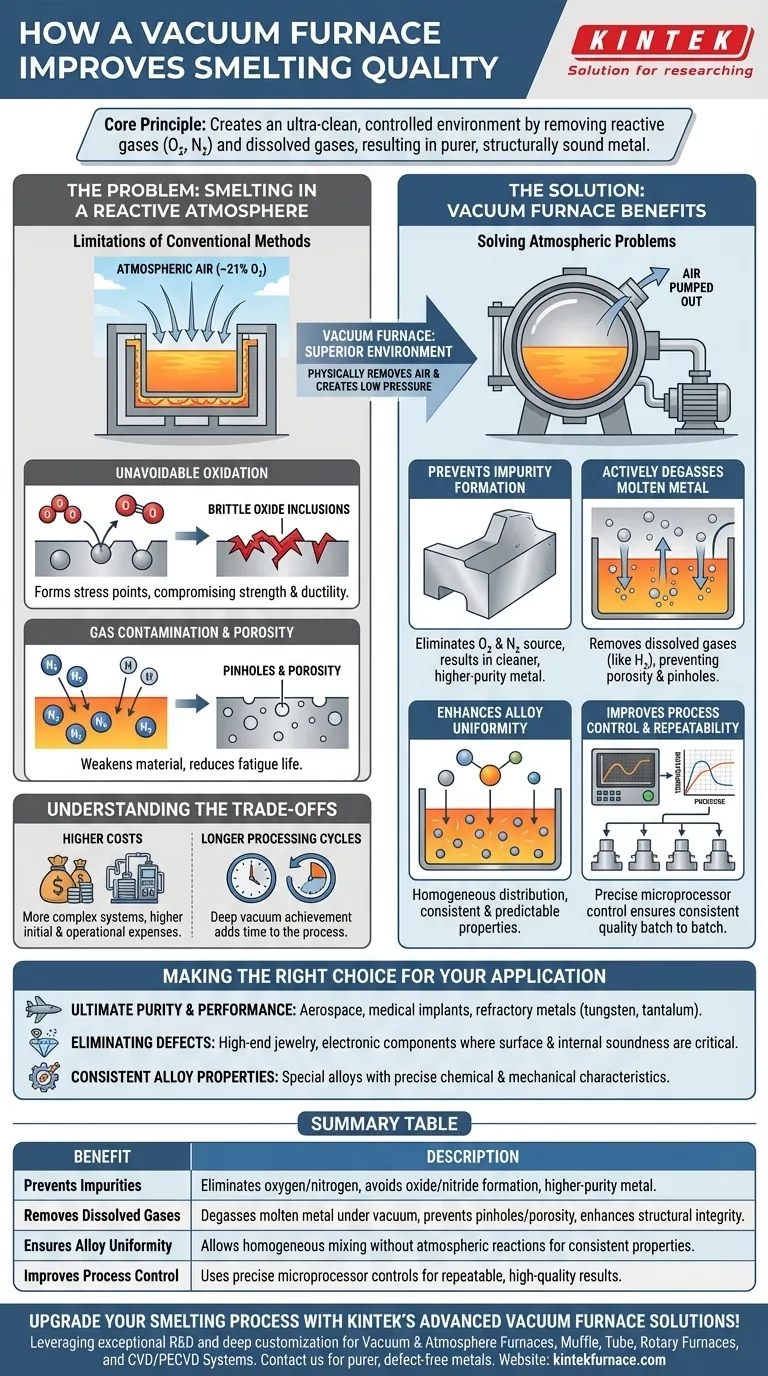

At its core, a vacuum furnace improves smelting quality by creating an ultra-clean, controlled environment that is impossible to achieve in a normal atmosphere. By removing reactive gases like oxygen and nitrogen, it prevents the formation of impurities and allows for the removal of dissolved gases from the molten metal, resulting in a fundamentally purer and structurally sound final product.

The primary advantage of vacuum smelting is not just what it adds, but what it removes. By eliminating the atmosphere, you eliminate the primary source of contamination, enabling the creation of metals with superior purity, fewer defects, and enhanced material properties.

The Problem: Smelting in a Reactive Atmosphere

To understand the value of a vacuum, we must first recognize the limitations of conventional smelting in the open air or even in a standard furnace.

Unavoidable Oxidation

Atmospheric air is approximately 21% oxygen, which is highly reactive with most metals, especially at high temperatures. This reaction, called oxidation, forms brittle oxide inclusions within the metal.

These oxides act as stress points, compromising the material's mechanical strength and ductility.

Gas Contamination and Porosity

Gases like nitrogen and hydrogen can dissolve into molten metal. As the metal cools and solidifies, the solubility of these gases decreases dramatically.

The trapped gas tries to escape, forming tiny bubbles that become pinholes and porosity in the final casting. These voids significantly weaken the material and reduce its fatigue life.

How Vacuum Furnaces Create a Superior Environment

A vacuum furnace directly solves these atmospheric problems by physically removing the air and creating a stable, low-pressure environment.

Preventing Impurity Formation

By pumping the atmosphere out of the chamber, the source of oxygen and nitrogen is virtually eliminated. This prevents the formation of oxide and nitride impurities from the start.

The result is a cleaner, higher-purity metal with far fewer non-metallic inclusions.

Actively Degassing the Molten Metal

The low-pressure environment does more than just prevent contamination; it actively cleanses the metal.

Under vacuum, dissolved gases like hydrogen are literally pulled out of the molten bath. This degassing process is critical for preventing the porosity and pinholes that plague conventional castings.

Enhancing Alloy Uniformity

In the clean, inert environment of a vacuum, alloying elements can be introduced and mixed without the risk of reacting with atmospheric gases.

This ensures a more homogenous and uniform distribution of elements throughout the melt, leading to alloys with more consistent and predictable properties.

Improving Process Control and Repeatability

Modern vacuum furnaces use microprocessor controls to precisely manage the entire heating and cooling cycle.

This level of control ensures that every batch is processed under the exact same conditions, eliminating variables and delivering highly repeatable, consistent quality from part to part.

Understanding the Trade-offs

While the benefits are significant, vacuum furnaces are not a universal solution. Their primary trade-offs are cost and cycle time.

Higher Initial and Operational Costs

Vacuum systems are inherently more complex than atmospheric furnaces. The equipment is more expensive to purchase, and the need for vacuum pumps and sophisticated seals increases maintenance and operational costs.

Longer Processing Cycles

Achieving and maintaining a deep vacuum takes time. The pump-down phase adds to the overall cycle time, which can make vacuum smelting a slower process compared to conventional methods.

Making the Right Choice for Your Application

The decision to use a vacuum furnace hinges entirely on your material requirements and performance goals.

- If your primary focus is ultimate purity and performance: For aerospace components, medical implants, or refractory metals (tungsten, tantalum), a vacuum furnace is non-negotiable.

- If your primary focus is eliminating defects: For applications like high-end jewelry or electronic components where surface finish and internal soundness are critical, vacuum processing is the superior choice.

- If your primary focus is consistent alloy properties: For creating special alloys with precise chemical compositions and mechanical characteristics, the control offered by a vacuum environment is essential.

Ultimately, vacuum smelting provides a level of control over the material's fundamental chemistry and structure that is simply unattainable in any other environment.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Impurities | Eliminates oxygen and nitrogen to avoid oxide/nitride formation, resulting in higher-purity metal. |

| Removes Dissolved Gases | Degasses molten metal under vacuum to prevent pinholes and porosity, enhancing structural integrity. |

| Ensures Alloy Uniformity | Allows homogeneous mixing of alloying elements without atmospheric reactions for consistent properties. |

| Improves Process Control | Uses precise microprocessor controls for repeatable, high-quality results in every batch. |

Upgrade your smelting process with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance options like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for purer, defect-free metals. Contact us today to discuss how our furnaces can enhance your material quality and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity