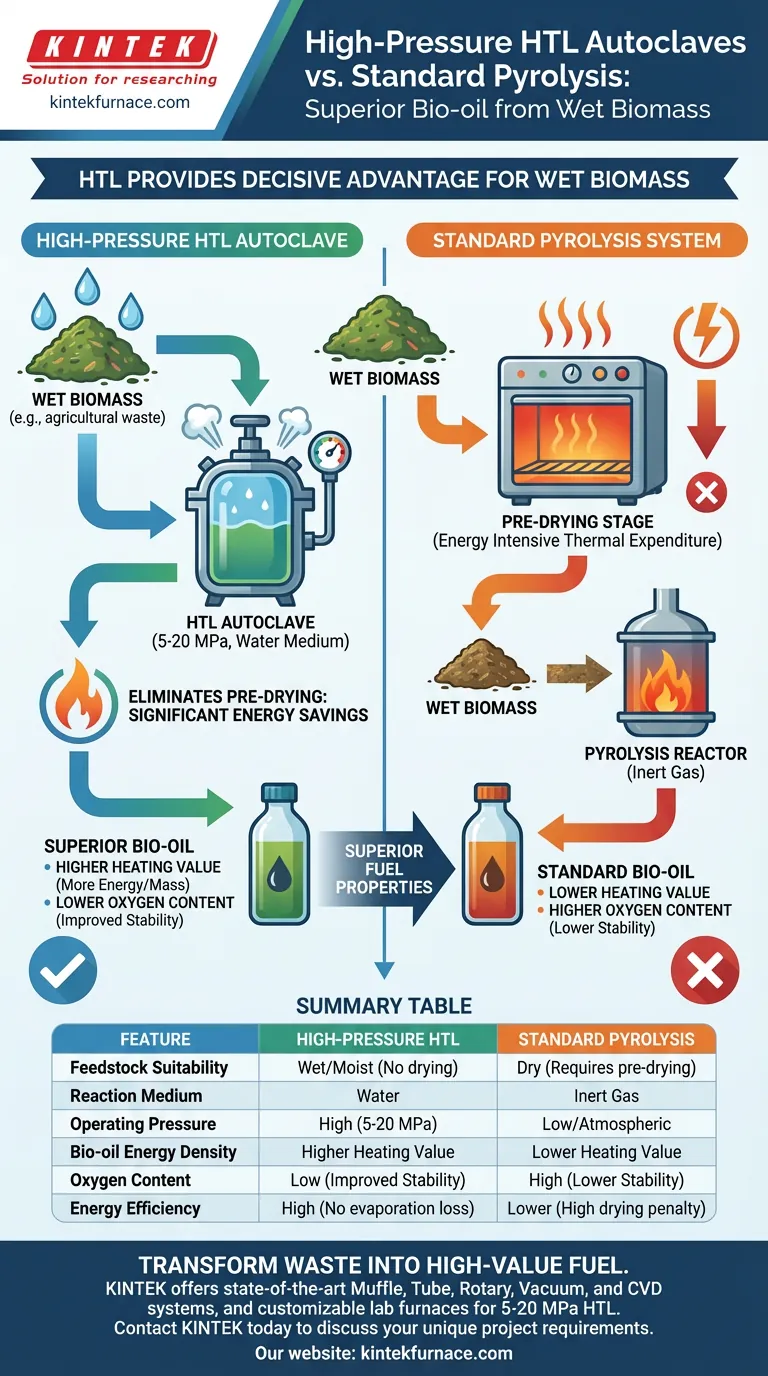

High-pressure autoclaves provide a decisive advantage when processing wet biomass by eliminating the pre-drying stage required by standard pyrolysis. Operating at pressures between 5 and 20 MPa with water as the reaction medium, these systems significantly reduce energy consumption and yield a bio-oil with superior fuel properties.

The strategic value of Hydrothermal Liquefaction (HTL) lies in its ability to turn moist agricultural waste into high-quality fuel without the energy penalty of drying, resulting in bio-oil with higher heating values and lower oxygen content.

Energy Efficiency and Feedstock Flexibility

Eliminating the Pre-Drying Step

Standard pyrolysis systems generally require dry biomass to function effectively. In contrast, HTL autoclaves utilize water as the primary reaction medium. This allows you to process wet feedstocks, such as moist agricultural waste, directly without strictly reducing moisture content first.

Reducing Energy Consumption

Because the pre-drying phase is eliminated, the overall energy footprint of the conversion process drops significantly. You avoid the substantial thermal energy expenditure typically needed to evaporate water from the biomass before processing begins.

The Role of High Pressure

To maintain water in the liquid phase at elevated temperatures, these autoclaves operate at substantial pressures, specifically between 5 and 20 MPa. This high-pressure environment facilitates the chemical breakdown of biomass within the aqueous medium.

Product Quality Improvements

Higher Heating Value

The output of HTL autoclaves is chemically distinct from standard pyrolysis oil. The bio-oil produced in these high-pressure systems typically features a higher heating value. This means the fuel produced contains more energy per unit of mass, making it a more potent energy source.

Lower Oxygen Content

Bio-oil stability and quality are often inversely related to oxygen levels. HTL produces bio-oil with a lower oxygen content compared to pyrolysis oil. This reduction in oxygen generally correlates with improved stability and compatibility for fuel applications.

Understanding the Operational Requirements

Managing High-Pressure Environments

While HTL offers product and efficiency benefits, it requires robust equipment management. The system must reliably sustain pressures of 5 to 20 MPa to function. This operational requirement dictates the need for specialized reactor design capable of handling high-stress conditions safely.

Making the Right Choice for Your Project

The decision between HTL and standard pyrolysis largely depends on your input material and your quality targets.

- If your primary focus is processing wet biomass: Choose HTL to bypass the energy-intensive drying process and reduce operational costs.

- If your primary focus is final fuel quality: Choose HTL to secure a bio-oil with higher energy density (heating value) and lower oxygen content.

By aligning your reactor choice with the moisture content of your feedstock, you maximize both energy efficiency and product value.

Summary Table:

| Feature | High-Pressure HTL Autoclave | Standard Pyrolysis System |

|---|---|---|

| Feedstock Suitability | Wet/Moist Biomass (No drying) | Dry Biomass (Requires pre-drying) |

| Reaction Medium | Water (Subcritical/Supercritical) | Inert Gas |

| Operating Pressure | High (5 - 20 MPa) | Low/Atmospheric |

| Bio-oil Energy Density | Higher Heating Value (HHV) | Lower Heating Value |

| Oxygen Content | Low (Improved Stability) | High (Lower Stability) |

| Energy Efficiency | High (No evaporation loss) | Lower (High drying penalty) |

Transform Your Waste into High-Value Fuel

Maximize your energy efficiency and fuel quality with KINTEK’s advanced high-pressure solutions. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temperature furnaces designed to handle the rigorous 5-20 MPa demands of Hydrothermal Liquefaction.

Whether you are processing moist agricultural waste or developing next-generation biofuels, our engineering team provides the specialized reactor designs you need for safety and performance. Contact KINTEK today to discuss your unique project requirements!

Visual Guide

References

- Jean de Dieu Marcel Ufitikirezi, Luboš Smutný. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. DOI: 10.3390/su16093617

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is vacuum brazing and what materials does it primarily join? Discover High-Purity Joining for Superior Bonds

- What are the primary differences in sintering strategies for ceramic membranes? Optimize Your Thermal Processing

- What is the typical heating process for steel castings in an annealing furnace? Achieve Optimal Microstructure and Stress Relief

- What are the benefits of vacuum hardening? Achieve Superior Surface Quality and Dimensional Accuracy

- What are the main applications of multi-chamber continuous vacuum furnaces? Boost High-Volume Industrial Efficiency

- What are the technical advantages of vacuum furnaces? Superior Heat Treatment for Steel & Alloys

- What role does a high-temperature vacuum furnace play in the synthesis of LaTiOC/NdTiOC? Master Heteroanionic Materials

- What advantages does laser active brazing offer compared to traditional furnace brazing? Precision Sealing Explored