At their core, multi-chamber continuous vacuum furnaces are used for high-volume industrial processes that require a controlled, oxygen-free environment. Their main applications include the vacuum heat treatment of metals, vacuum sintering of powder metallurgy and metal injection molded parts, vacuum brazing of complex assemblies, and the degassing and sealing of electronic components and vacuum-insulated containers.

The critical distinction is not just what these furnaces do, but how they do it. While a single-chamber furnace performs these same processes in batches, a multi-chamber continuous furnace transforms them into an automated, assembly-line-style operation for mass production, delivering significant gains in throughput and energy efficiency.

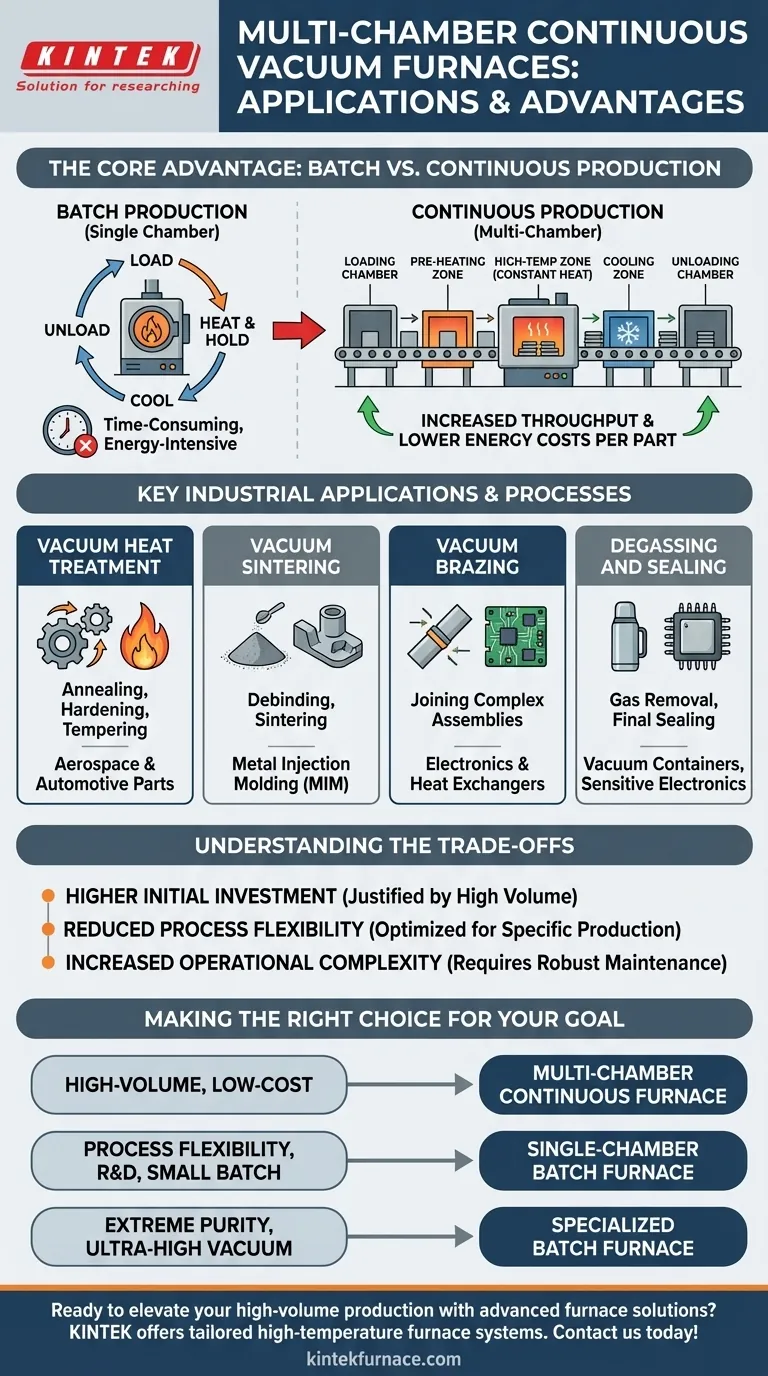

The Core Advantage: Moving from Batch to Continuous Production

The decision to use a multi-chamber furnace is fundamentally a strategic one about production scale. It represents a shift from processing individual batches to creating a continuous, uninterrupted flow of material.

Why Continuous Processing Matters

A standard single-chamber, or "batch," furnace performs every step in one location. The chamber is loaded, sealed, pumped down to a vacuum, heated, held at temperature, cooled, and vented before it can be unloaded. This entire thermal cycle is time-consuming and energy-intensive.

How a Multi-Chamber System Works

A multi-chamber continuous furnace breaks this cycle into a series of specialized, connected modules. A typical line includes a loading chamber, a pre-heating zone, the main high-temperature processing zone, a cooling zone, and an unloading chamber.

Parts are moved between these modules on a roller or belt-based transmission system. Crucially, pneumatic gate valves isolate each chamber, allowing the central high-temperature zone to remain consistently hot and under vacuum while parts enter and exit the system.

The Impact on Throughput and Efficiency

This design provides two decisive advantages. First, throughput is dramatically increased because you no longer wait for a single chamber to complete an entire heating and cooling cycle. Second, energy costs per part are significantly lower because the main furnace is not repeatedly cooled and reheated, which also reduces wear and maintenance on heating elements and insulation.

Key Industrial Applications and Processes

While the technology enables high volume, the applications themselves demand the unique qualities of a vacuum environment—namely, preventing oxidation and contamination to ensure material purity and integrity.

Vacuum Heat Treatment

This involves altering the physical and mechanical properties of a material. A continuous furnace is ideal for high-volume treatments like annealing (softening), hardening, and tempering of metal parts used in the aerospace and automotive industries.

Vacuum Sintering

Sintering fuses powdered materials into a solid mass using heat. Multi-chamber furnaces are essential for the Metal Injection Molding (MIM) industry, which produces massive quantities of small, complex metal parts. The continuous flow allows for both debinding (removing a binder agent) and sintering in a seamless process.

Vacuum Brazing

Brazing joins two or more metal items by melting a filler metal between them. In a vacuum, the joints are exceptionally clean and strong. Continuous furnaces are used to braze components for electronics or high-performance heat exchangers at scale.

Degassing and Sealing

This process removes trapped gases from a material or device. A prime example is the production of stainless steel vacuum containers (like thermal flasks) or the final sealing of sensitive electronic devices where internal atmospheric contamination must be eliminated.

Understanding the Trade-offs

While powerful, a multi-chamber continuous system is not the right solution for every problem. Objectivity requires acknowledging its limitations.

Higher Initial Investment

A multi-chamber line is a significant capital expenditure. Its cost is substantially higher than a batch furnace, and the investment can only be justified by high-volume production needs.

Reduced Process Flexibility

These systems are typically designed and optimized for a specific process and part geometry. They lack the flexibility of a batch furnace, which can be easily reprogrammed for a wide variety of heat cycles, part sizes, and materials on a day-to-day basis.

Increased Operational Complexity

With rollers, multiple gate valves, and multi-zone temperature controls, a continuous furnace is a more complex piece of machinery. While maintenance on the hot zone is reduced, the overall system has more moving parts that require a robust preventative maintenance program.

Making the Right Choice for Your Goal

Selecting the correct furnace type depends entirely on your operational goals and production volume.

- If your primary focus is high-volume, low-cost-per-part production: A multi-chamber continuous furnace is the definitive choice for a consistent, repeatable process.

- If your primary focus is process flexibility, R&D, or small-batch custom work: A single-chamber batch furnace provides the necessary agility and lower initial cost.

- If your primary focus is extreme purity and ultra-high vacuum levels: Specialized batch furnaces are often preferred for applications like semiconductor crystal growth, as maintaining the highest vacuum is simpler in a single, static chamber.

Ultimately, understanding the fundamental difference between continuous and batch processing empowers you to align your equipment investment with your long-term production strategy.

Summary Table:

| Application | Key Processes | Industries |

|---|---|---|

| Vacuum Heat Treatment | Annealing, hardening, tempering | Aerospace, automotive |

| Vacuum Sintering | Debinding, sintering | Metal Injection Molding (MIM) |

| Vacuum Brazing | Joining with filler metal | Electronics, heat exchangers |

| Degassing and Sealing | Gas removal, sealing | Vacuum containers, electronics |

Ready to elevate your high-volume production with advanced furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, enhanced by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our expertise can boost your throughput and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today