The typical heating process for annealing steel castings is a three-stage metallurgical treatment involving heating the material to a specific temperature, holding it there, and then cooling it in a controlled manner. For many common steels, this involves heating to approximately 950°C to transform the internal crystal structure into a uniform state known as austenite. This process is fundamental for relieving internal stresses and refining the grain structure of the casting.

The core purpose of annealing is not simply to heat metal, but to precisely manipulate its internal microstructure. The goal is to relieve stresses, increase ductility, and improve machinability by creating a softer, more uniform material state.

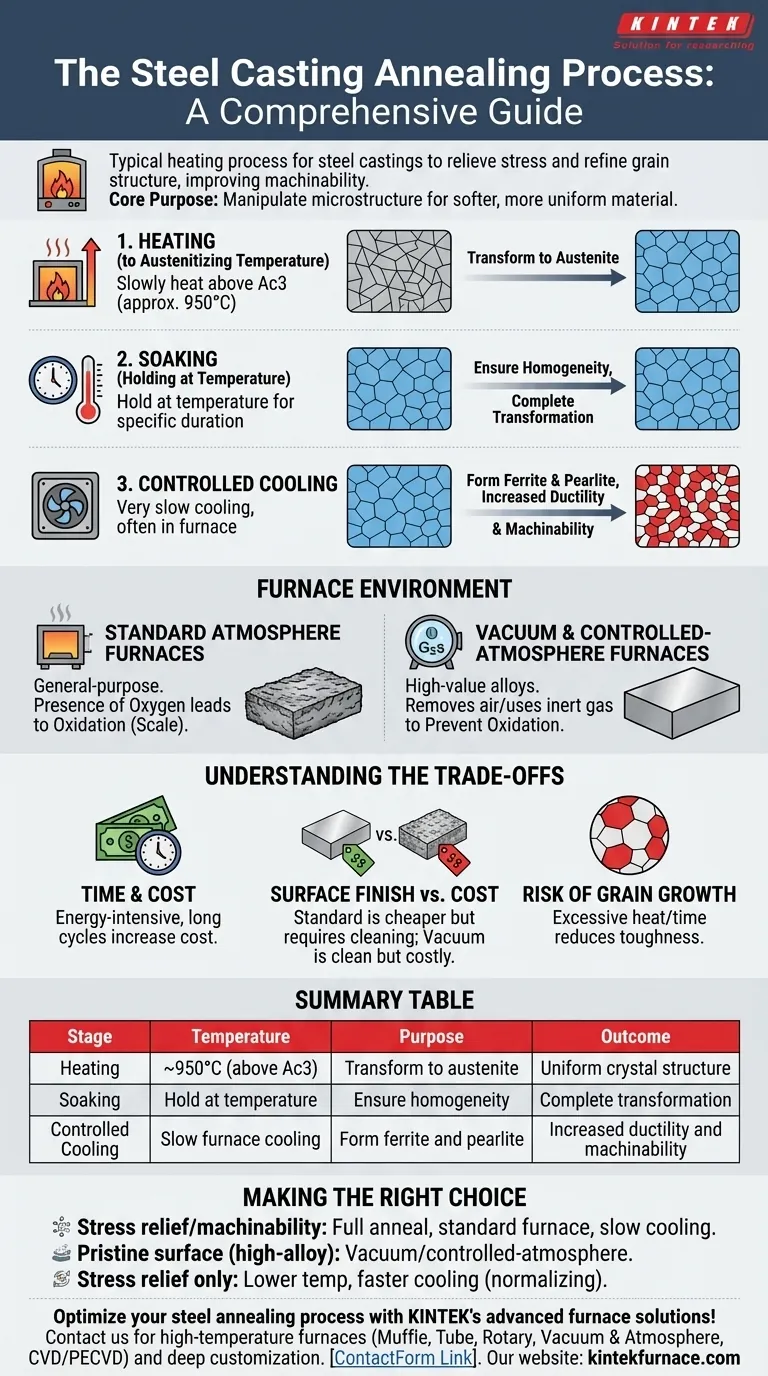

The Three Core Stages of Annealing Steel Castings

The annealing process can be broken down into three distinct and critical phases. Each stage serves a specific metallurgical purpose.

Stage 1: Heating to the Austenitizing Temperature

The first step is to slowly and uniformly heat the steel casting to a temperature above its upper critical transformation point (Ac3). This is the temperature at which the steel’s ferrite and pearlite structure fully transforms into austenite, a uniform solid solution.

As a general rule, this temperature is often set to be 100-200°C above the austenite formation temperature, which for many common steel alloys is around 950°C.

Stage 2: Soaking (Holding at Temperature)

Once the target temperature is reached, the casting is "soaked" or held at that temperature for a specific duration. The goal of this stage is to ensure that the temperature is uniform throughout the entire casting, even in its thickest sections.

This holding period allows the transformation to austenite to complete fully and for the chemical composition to become homogeneous. The exact time depends on the casting's thickness and the steel's specific alloy composition.

Stage 3: Controlled Cooling

The final and perhaps most critical stage is cooling. For a full anneal, the casting is cooled very slowly, often by simply turning off the furnace and allowing it to cool with the part still inside.

This slow cooling rate allows the austenite to transform back into a soft, coarse microstructure of ferrite and pearlite. This refined structure is what gives the annealed steel its high ductility and improved machinability. Faster cooling, such as in open air, results in a different process called normalizing, which also relieves stress but produces a harder material.

The Role of the Furnace Environment

The atmosphere inside the furnace during annealing has a significant impact on the final product, especially on its surface condition.

Standard Atmosphere Furnaces

Most general-purpose annealing is performed in standard box-type furnaces. While effective, the presence of oxygen at high temperatures will cause oxidation, forming a layer of scale on the casting's surface. This scale must typically be removed later through processes like shot blasting or machining.

Vacuum and Controlled-Atmosphere Furnaces

For high-value alloys like stainless steel or titanium alloys, or for parts where a pristine surface is critical, vacuum or controlled-atmosphere furnaces are used.

The process in a vacuum furnace involves removing all air before heating. After soaking, the part is cooled with a non-reactive inert gas or another controlled method. This completely prevents oxidation and surface contamination, preserving the material's surface integrity.

Understanding the Trade-offs

While essential, the annealing process is not without its considerations. Understanding these trade-offs is key to making sound engineering decisions.

Time and Cost

Annealing is an energy-intensive process. The long cycles of heating, soaking, and especially slow cooling mean that furnaces are occupied for extended periods, contributing significantly to the final cost of the part.

Surface Finish vs. Cost

Using a standard furnace is cheaper but requires secondary operations to remove scale. A vacuum or controlled-atmosphere process delivers a clean part directly from the furnace but comes at a much higher operational cost.

Risk of Grain Growth

If the soaking temperature is too high or the holding time is excessively long, the austenite grains can begin to grow too large. This excessive grain growth can be detrimental, reducing the material's toughness and impact strength.

Making the Right Choice for Your Goal

Selecting the correct annealing parameters depends entirely on the material and the desired outcome for the finished part.

- If your primary focus is stress relief and machinability for standard carbon steel castings: A full anneal in a standard furnace followed by slow furnace cooling is the most common and cost-effective approach.

- If your primary focus is a pristine surface finish on high-alloy or stainless steels: A vacuum or controlled-atmosphere furnace is necessary to prevent oxidation and deliver a clean, uncontaminated part.

- If your primary focus is only relieving internal stresses from welding or casting: A lower-temperature stress relief anneal or a faster air-cooling process (normalizing) may be a more efficient solution.

Ultimately, mastering the annealing process is about precisely controlling temperature, time, and atmosphere to achieve the desired material microstructure.

Summary Table:

| Stage | Temperature | Purpose | Outcome |

|---|---|---|---|

| Heating | ~950°C (above Ac3) | Transform to austenite | Uniform crystal structure |

| Soaking | Hold at temperature | Ensure homogeneity | Complete transformation |

| Controlled Cooling | Slow furnace cooling | Form ferrite and pearlite | Increased ductility and machinability |

Optimize your steel annealing process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and material quality. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a double-chamber device preferred over a standard electric furnace for sintering? Achieve Oxidation-Free Results

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?