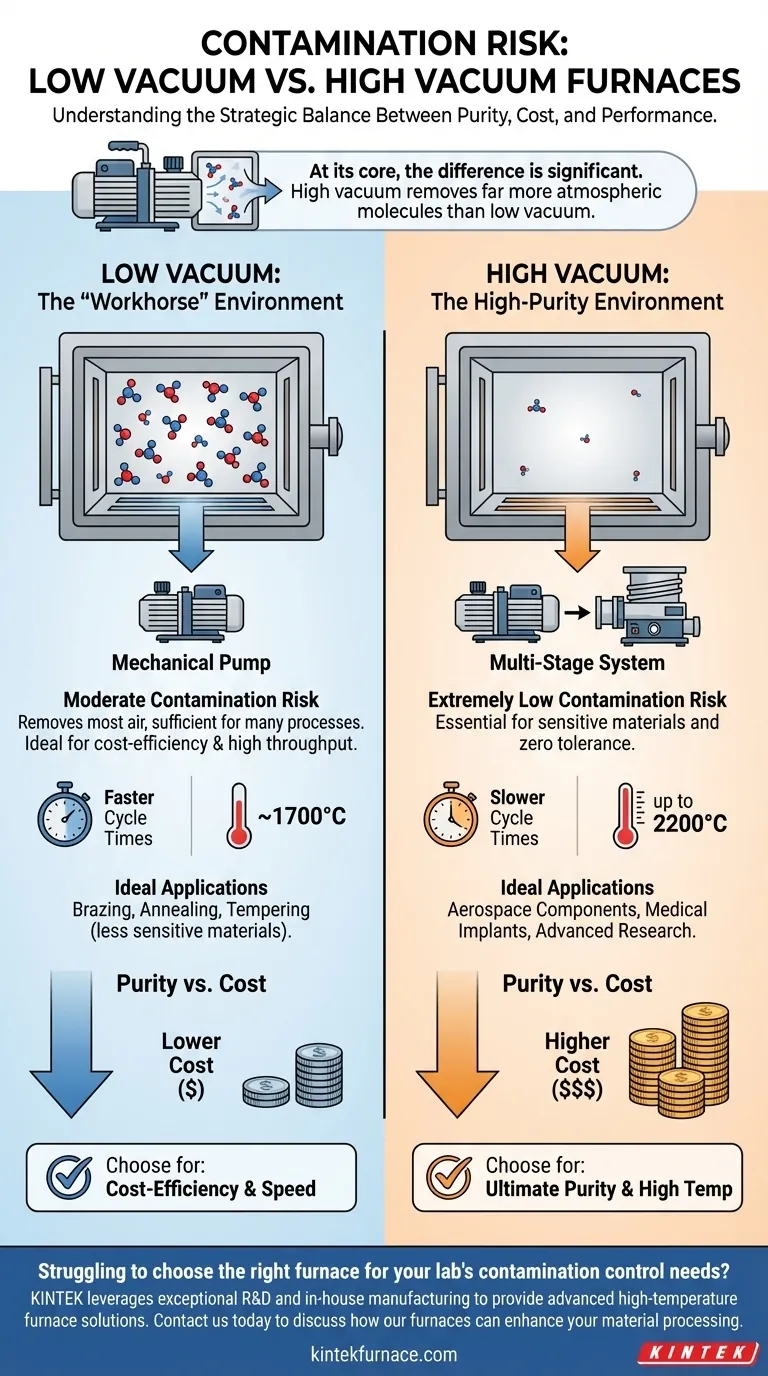

At its core, the difference is significant. High vacuum furnaces provide an environment with an extremely low risk of contamination, whereas low vacuum furnaces present a moderate contamination risk. This distinction arises from the level of atmospheric molecules each system is designed to remove during a process cycle.

The choice between a low and high vacuum furnace is not simply about minimizing contamination. It is a strategic decision that balances the required material purity against critical operational factors like cost, cycle time, and temperature capability.

The Source of Contamination: Understanding Vacuum Levels

To understand the risk, you must first understand what a vacuum furnace does. Its primary job is to remove reactive atmospheric gases—like oxygen, nitrogen, and water vapor—that can contaminate, oxidize, or otherwise compromise the material being processed. The level of vacuum determines how effectively these gases are removed.

Low Vacuum: The "Workhorse" Environment

Low vacuum furnaces, sometimes called atmosphere furnaces, use mechanical pumps like rotary vane pumps. These are effective at removing the vast majority of air from the chamber.

However, a "low vacuum" still contains a measurable number of residual atmospheric molecules. This environment is sufficient for many heat treatment processes, but the remaining gases create a moderate risk of contamination for highly sensitive materials.

High Vacuum: The High-Purity Environment

High vacuum systems achieve a much lower-pressure environment by using a multi-stage pumping system. After an initial mechanical pump removes the bulk of the air, a secondary pump—such as a turbomolecular or diffusion pump—takes over.

This second stage removes far more of the remaining molecules. The result is an exceptionally clean environment with minimal reactive gases, creating an extremely low risk of contamination. This level of purity is essential for processing reactive metals or manufacturing components with zero tolerance for impurities.

Understanding the Trade-offs

Choosing the right vacuum level is a matter of balancing competing priorities. The superior purity of a high vacuum furnace comes with distinct operational and financial costs.

Purity vs. Cost

The advanced, multi-stage pumping systems and robust chamber engineering required for high vacuum make these furnaces significantly more expensive. They have a higher initial investment and higher ongoing maintenance costs compared to the simpler and more economical low vacuum systems.

Purity vs. Throughput

Achieving an ultra-high vacuum level is not instantaneous. The pump-down process for a high vacuum furnace is considerably slower than for a low vacuum furnace. This results in longer overall cycle times, which directly impacts production throughput. Low vacuum systems offer faster cycles, making them more suitable for high-volume operations.

Purity vs. Temperature Capability

High vacuum furnaces are typically engineered for more demanding applications. As a result, they can often reach higher maximum temperatures (up to 2200°C). This capability is necessary for processing advanced ceramics, refractories, and certain alloys. Low vacuum furnaces generally operate at lower maximum temperatures, typically around 1700°C.

Making the Right Choice for Your Process

Your decision should be driven by the specific requirements of your material and your operational goals.

- If your primary focus is ultimate material purity and high-temperature processing: A high vacuum furnace is the correct choice, as it is essential for sensitive applications like aerospace components, medical implants, or advanced research.

- If your primary focus is cost-efficiency and high throughput for less sensitive materials: A low vacuum furnace offers a practical and economical solution for processes like general-purpose brazing, annealing, or tempering.

By aligning the furnace's capabilities with your specific material and production requirements, you ensure both process integrity and operational success.

Summary Table:

| Vacuum Type | Contamination Risk | Key Characteristics | Ideal Applications |

|---|---|---|---|

| Low Vacuum | Moderate | Lower cost, faster cycle times, up to ~1700°C | Brazing, annealing, tempering of less sensitive materials |

| High Vacuum | Extremely Low | Higher cost, slower cycles, up to 2200°C | Aerospace components, medical implants, advanced research |

Struggling to choose the right furnace for your lab's contamination control needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique requirements. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you need the high purity of a high vacuum furnace or the cost-efficiency of a low vacuum system, we can help you achieve precise results. Contact us today to discuss how our furnaces can enhance your material processing and boost your operational success!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations