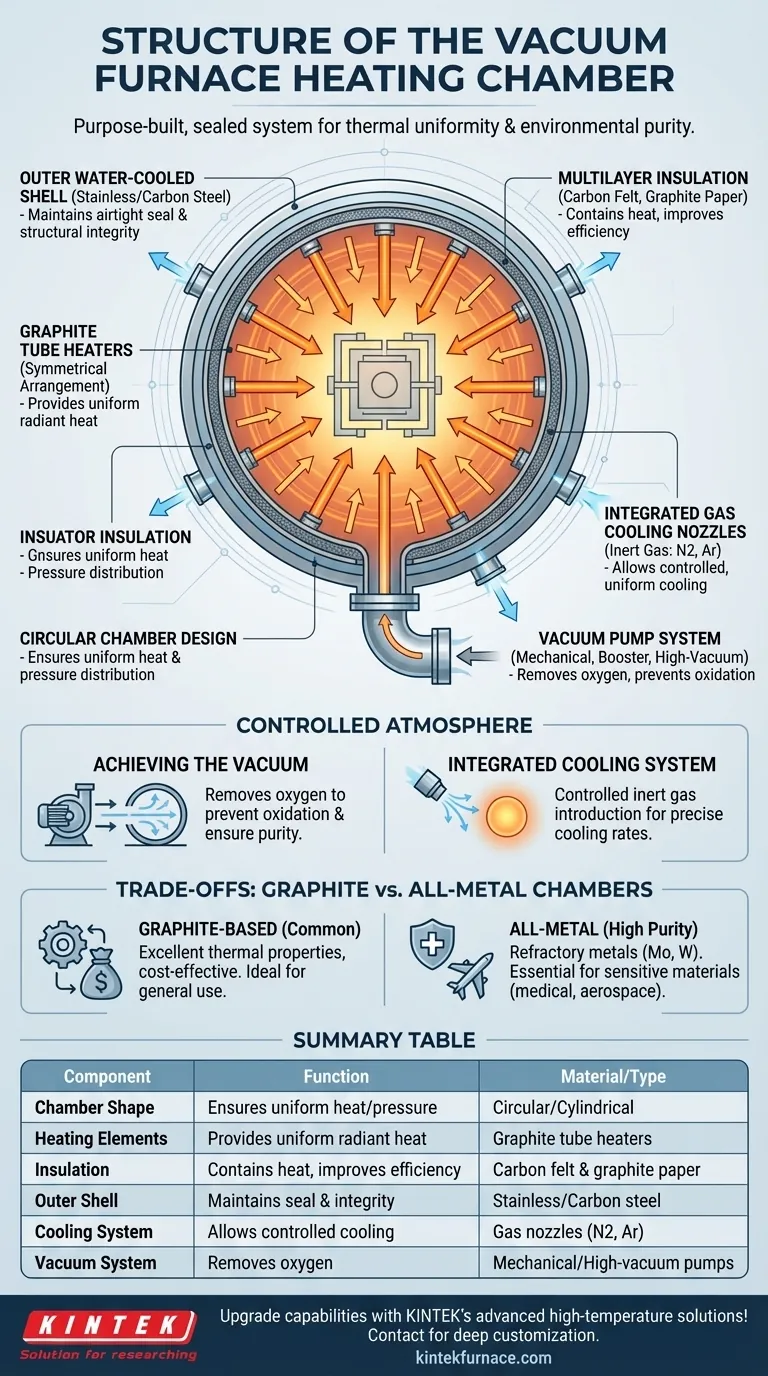

At its core, a vacuum furnace heating chamber is a purpose-built, sealed system designed for thermal uniformity and environmental purity. The most common configuration is a circular chamber lined with insulation, featuring uniformly distributed graphite heaters and gas cooling nozzles to precisely control the entire heat treatment cycle.

The design of a heating chamber is not just about containing heat; it is a sophisticated system where every component—from the shape of the chamber to the type of insulation—works in concert to create a perfectly controlled, oxygen-free environment for processing materials.

Deconstructing the Core Components

To understand how a vacuum furnace functions, we must first examine its essential structural elements. Each part serves a distinct and critical purpose in achieving the desired process conditions.

The Circular Chamber Design

The chamber itself is almost always circular. This cylindrical shape is not arbitrary; it ensures that heat from the elements and pressure from the vacuum are distributed evenly across the workload. This uniformity is critical for consistent material properties after treatment.

Heating Elements: The Engine of the Furnace

The heat is generated by graphite tube heaters. These elements are arranged symmetrically around the chamber's 360-degree perimeter. This placement guarantees that heat radiates uniformly inward, eliminating hot or cold spots on the material being processed. Graphite is chosen for its efficiency, simple installation, and low failure rates in high-temperature, vacuum environments.

Insulation Layers: Containing the Heat

Containing extreme temperatures is the job of the insulation. This is typically achieved with multiple layers of high-grade carbon felt and flexible graphite paper. These materials act as highly effective heat shields, preventing thermal energy from escaping. This makes the furnace efficient and also keeps the structure relatively lightweight.

The Outer Shell and Frame: Providing Integrity

The entire assembly is housed within a durable frame, often made of stainless steel for easy maintenance. The outer vacuum shell, welded from carbon steel or stainless steel, creates the airtight seal. This shell is often water-cooled to prevent it from deforming under the intense internal heat.

The Controlled Atmosphere: More Than Just Heat

A vacuum furnace's primary advantage is its ability to control the processing atmosphere. This is achieved through the integration of vacuum and cooling systems directly into the chamber's structure.

Achieving the Vacuum

After the chamber is sealed, a system of vacuum pumps is used to evacuate all air and, most importantly, oxygen. Depending on the required vacuum level, this can involve a combination of mechanical, booster, and high-vacuum pumps like diffusion or turbo-molecular pumps.

The Importance of a Pure Environment

By removing oxygen, the vacuum prevents oxidation and other chemical reactions that would otherwise occur at high temperatures. This ensures the surface finish and metallurgical properties of the material remain pure and uncontaminated throughout the process.

Integrated Cooling System

Heat treatment doesn't end with heating. Cooling gas nozzles, distributed alongside the heaters, allow for the introduction of an inert gas (like nitrogen or argon) to cool the material at a controlled rate. This rapid and uniform cooling is essential for achieving specific material hardness and microstructures.

Understanding the Trade-offs: Graphite vs. All-Metal

While graphite-based chambers are the standard, they are not the only option. Understanding the alternative reveals the design principles at play.

The Graphite-Based Chamber

This is the most common design due to its excellent thermal properties, efficiency, and cost-effectiveness. The use of carbon felt and graphite heaters is ideal for a vast range of general heat-treating, brazing, and sintering applications.

The All-Metal Alternative

For applications where even trace amounts of carbon are unacceptable (such as in medical, aerospace, or certain electronics), an all-metal chamber is used. These chambers replace the graphite components with refractory metals like molybdenum or tungsten. This guarantees the highest level of purity but comes at a higher cost and often with increased weight.

Making the Right Choice for Your Application

The structure of the heating chamber directly impacts its performance capabilities. Your final decision should be guided by the specific demands of your material and process.

- If your primary focus is general-purpose heat treatment and cost-effectiveness: The standard graphite-lined circular chamber provides the best balance of performance and value.

- If your primary focus is processing highly sensitive materials where carbon contamination is unacceptable: An all-metal chamber is the necessary choice to ensure product purity.

- If your primary focus is process control and rapid cycling: Prioritize a design with highly uniform heating elements and an integrated, fast-response gas cooling system.

Ultimately, the heating chamber is an engineered environment where structure directly enables function.

Summary Table:

| Component | Function | Material/Type |

|---|---|---|

| Chamber Shape | Ensures uniform heat and pressure distribution | Circular/Cylindrical |

| Heating Elements | Provides uniform radiant heat | Graphite tube heaters |

| Insulation | Contains heat and improves efficiency | Carbon felt and graphite paper |

| Outer Shell | Maintains airtight seal and structural integrity | Stainless steel or carbon steel |

| Cooling System | Allows controlled cooling with inert gases | Gas nozzles (e.g., nitrogen, argon) |

| Vacuum System | Removes oxygen to prevent oxidation | Mechanical, booster, and high-vacuum pumps |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision-engineered products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering superior thermal uniformity, purity, and efficiency. Contact us today to discuss how our tailored solutions can enhance your heat treatment processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion