In short, vacuum and protective atmosphere melting are used to fundamentally purify aerospace alloys during their creation. By melting materials in a controlled environment free of atmospheric gases, these processes eliminate the root cause of microscopic defects that would otherwise compromise the material's strength and reliability under extreme stress.

The core challenge in creating aerospace-grade superalloys is not just mixing the right elements, but preventing those elements from reacting with the air during melting. Vacuum and protective atmosphere techniques are the definitive solution, transforming a standard metal into a material pure enough for the most demanding applications.

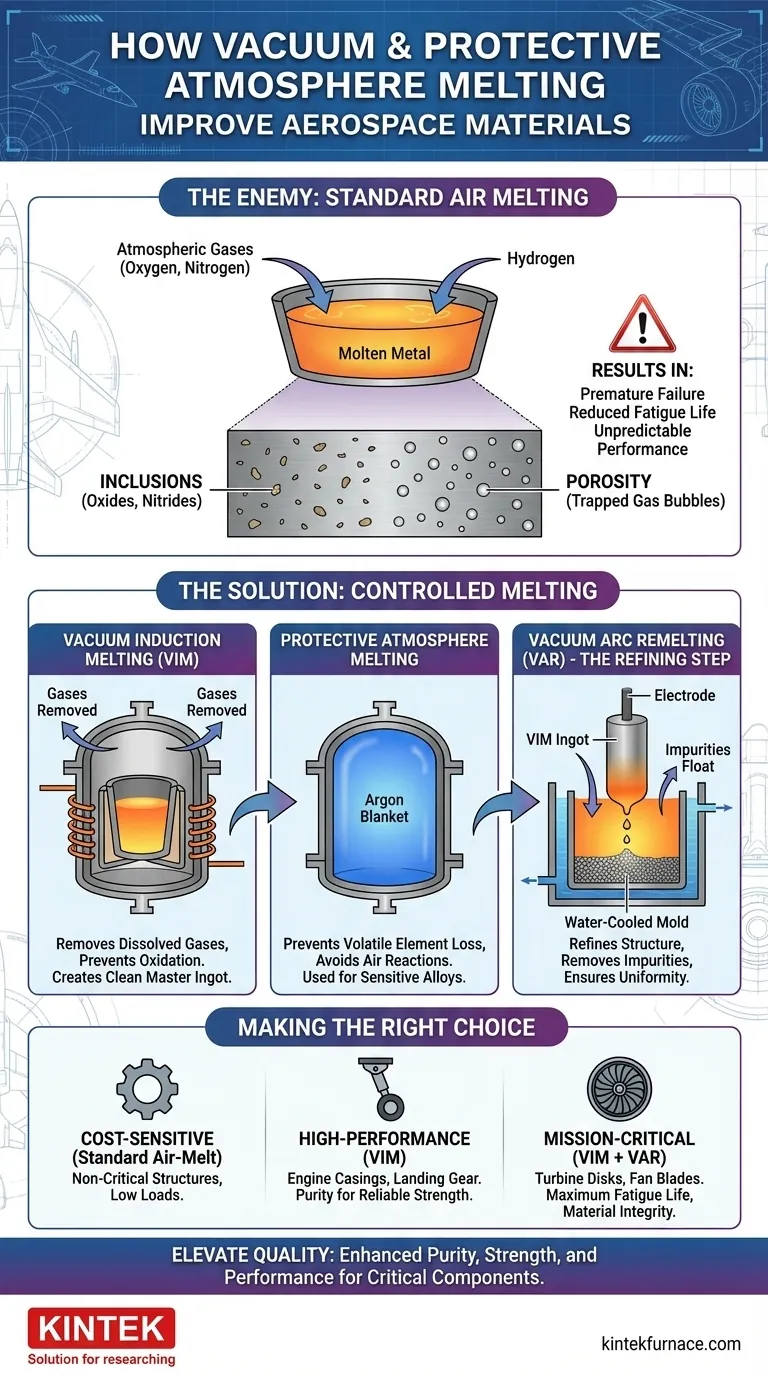

The Enemy: Why Standard Air Melting Fails

To understand the value of vacuum melting, you must first understand the problem it solves. When metal is melted in open air, it is exposed to a highly reactive environment that introduces critical flaws.

Oxygen and Nitrogen Contamination

Molten metal is highly reactive with the oxygen (~21%) and nitrogen (~78%) in the air. These reactions form microscopic oxides and nitrides within the liquid metal.

As the metal solidifies, these non-metallic compounds are trapped, creating hard, brittle particles known as inclusions. Inclusions act as stress concentration points, initiating cracks and leading to premature failure.

Hydrogen and Porosity

Hydrogen gas can easily dissolve into molten metal. As the metal cools and solidifies, its ability to hold dissolved hydrogen plummets.

The excess hydrogen is forced out of the solution, forming tiny gas bubbles that become trapped in the solid structure. This results in porosity—a network of microscopic voids that severely reduces the material's density and load-bearing capacity.

The Impact on Mechanical Properties

For an aerospace component like a turbine blade, which spins at thousands of RPM at extreme temperatures, these defects are catastrophic. They dramatically reduce fatigue life, ductility, and fracture toughness, making material performance unpredictable and unreliable.

The Solution: Controlling the Melting Environment

Vacuum and protective atmosphere melting directly remove the atmospheric contaminants that cause these defects, resulting in an exceptionally clean and uniform material.

Vacuum Induction Melting (VIM)

VIM is often the first step. The raw alloy materials are placed in a crucible inside a sealed chamber, and a powerful vacuum is pulled.

The melting process then begins, powered by electromagnetic induction. The vacuum environment actively pulls dissolved gases like hydrogen and nitrogen out of the molten bath and, crucially, prevents any reaction with oxygen. This produces a very clean master ingot.

Protective Atmosphere Melting

In some cases, a full vacuum is not ideal, as it can cause essential, volatile alloying elements to boil off. Here, an inert gas like argon is used.

The chamber is first evacuated and then backfilled with high-purity argon. This creates a positive pressure that prevents air from leaking in while providing a non-reactive "protective blanket" over the molten metal.

Vacuum Arc Remelting (VAR): The Refining Step

For the most critical applications, the ingot produced by VIM undergoes a second refining process called VAR. The VIM ingot is used as a giant electrode in another vacuum chamber.

A powerful electric arc is struck, causing the electrode to melt drop by drop into a water-cooled copper mold below. This slow, controlled remelting and solidification process provides two key benefits:

- It gives any remaining impurities time to float to the top of the molten pool.

- It creates a highly uniform and fine-grained final structure, further enhancing mechanical properties.

Understanding the Trade-offs

While these processes deliver unparalleled quality, that performance comes at a cost.

Significant Cost Increase

Vacuum furnaces and the associated equipment represent a massive capital investment. The energy consumption and maintenance requirements are also substantially higher than for standard air-melt furnaces.

Slower Production Rates

VIM and VAR are batch processes that require significant time for chamber pump-down, melting, and cooling. This makes them inherently slower and less scalable than continuous air melting, directly impacting throughput.

Process Complexity

Operating this equipment requires highly skilled technicians and stringent process controls. Any failure in the vacuum systems or process parameters can compromise an entire expensive batch of material.

Making the Right Choice for Your Application

The necessity of these advanced melting techniques is directly proportional to the criticality of the component's function.

- If your primary focus is cost-sensitive, non-critical structures: Standard air-melted alloys may be perfectly adequate for applications where loads are low and failure is not catastrophic.

- If your primary focus is high-performance, stressed components: VIM is the essential baseline for parts like engine casings or landing gear, where purity is required for reliable strength.

- If your primary focus is mission-critical, rotating components: A dual VIM/VAR process is the non-negotiable standard for parts like turbine disks and fan blades, where maximum fatigue life and material integrity are paramount.

Ultimately, the integrity of an aerospace material is the foundation of its safety and performance, a standard set by controlling its environment from the very first melt.

Summary Table:

| Process | Key Benefits | Common Applications |

|---|---|---|

| Vacuum Induction Melting (VIM) | Removes dissolved gases, prevents oxidation | Engine casings, landing gear |

| Protective Atmosphere Melting | Prevents element loss, avoids air reactions | Alloys with volatile elements |

| Vacuum Arc Remelting (VAR) | Refines structure, removes impurities | Turbine disks, fan blades |

Elevate your aerospace material quality with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces, as well as CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering enhanced purity, strength, and performance for critical components. Don't let impurities compromise your results—contact us today to discuss how we can support your high-performance applications!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production