At their core, vacuum furnaces are important because they create a chemically pure, highly controlled environment for heat treatment. By removing air and other atmospheric gases that cause unwanted reactions like oxidation, they enable the manufacturing of materials with superior strength, purity, and performance that are impossible to achieve with conventional furnaces.

The fundamental value of a vacuum furnace isn't just the heat it provides, but the environment it creates. By eliminating atmospheric contamination, it unlocks the true potential of advanced materials, making it indispensable for high-stakes industries.

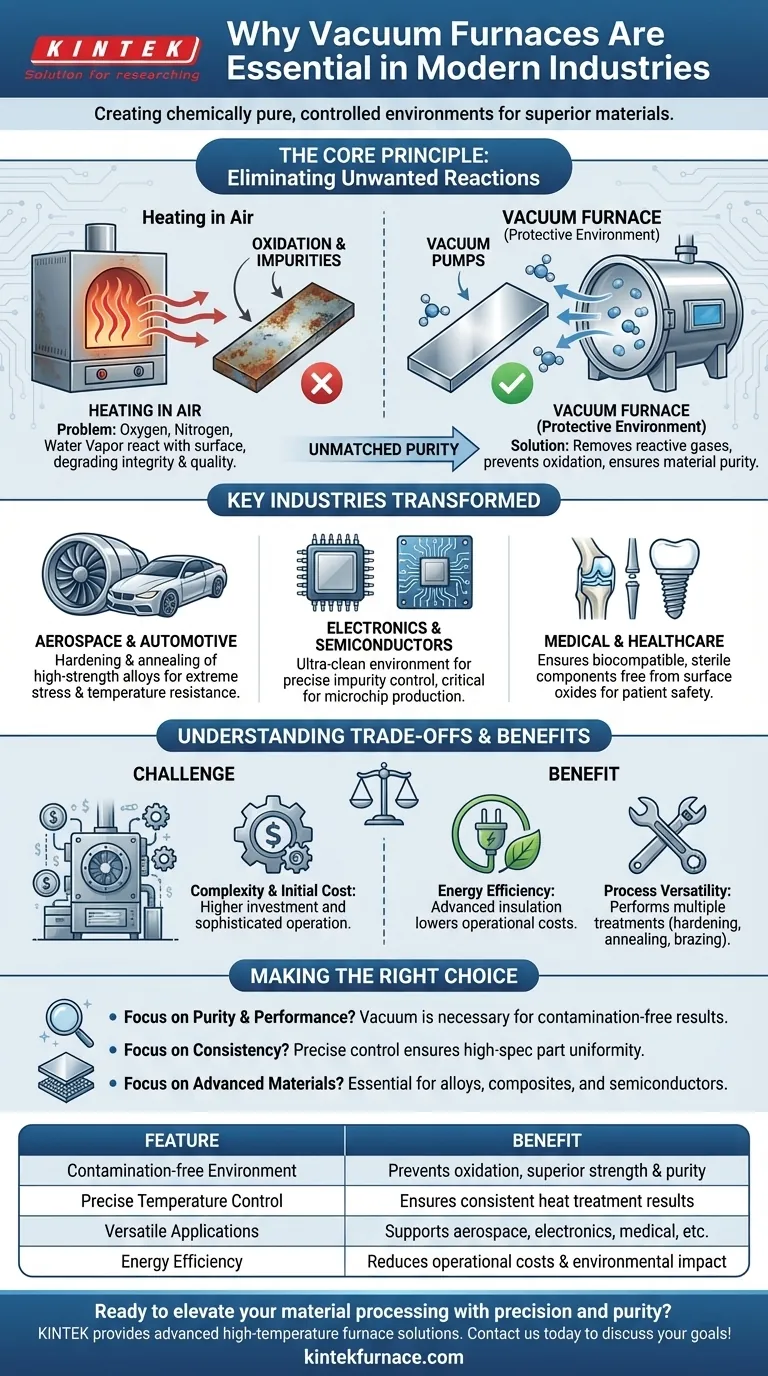

The Core Principle: Eliminating Unwanted Reactions

The primary advantage of a vacuum furnace lies in its ability to control the processing atmosphere with extreme precision. This control directly prevents the negative effects of heating materials in the open air.

The Problem with Heating in Air

When materials are heated in a traditional furnace, they are exposed to oxygen, nitrogen, and water vapor present in the air. These elements can react with the material's surface, causing oxidation (rust), discoloration, and the introduction of impurities.

These reactions degrade the material's structural integrity, electrical properties, and overall quality, making it unsuitable for high-performance applications.

How a Vacuum Provides Protection

A vacuum furnace works by pumping nearly all the air out of a sealed chamber before the heating process begins. This creates an environment that is almost entirely free of reactive gases.

By removing the atmosphere, the furnace eliminates the possibility of oxidation and other surface contamination. The vacuum itself becomes the protective "atmosphere," ensuring the material's chemical composition remains unchanged.

Achieving Unmatched Material Purity

This contamination-free environment is critical in industries where even microscopic impurities can lead to catastrophic failure. The process ensures the uniformity of metal alloy compositions and the creation of perfectly clean surfaces.

This is why vacuum furnaces are essential for producing sensitive electronic components, medical implants, and critical aerospace parts.

Key Industries Transformed by Vacuum Technology

The unique capabilities of vacuum furnaces make them a cornerstone technology across several advanced manufacturing sectors.

Aerospace and Automotive

In these industries, components must be both incredibly strong and lightweight. Vacuum furnaces are used for processes like hardening and annealing of high-strength alloys.

This results in parts that can withstand extreme stress and temperature without compromising their structural integrity, a requirement for jet engine turbines and high-performance vehicle components.

Electronics and Semiconductors

The semiconductor industry relies on creating materials with precisely controlled impurity levels. A vacuum furnace provides the ultra-clean environment needed to manufacture highly sensitive electronic components.

Even the smallest amount of contamination can ruin a batch of microchips, making the controlled atmosphere of a vacuum furnace non-negotiable.

Medical and Healthcare

Materials used for medical implants, such as artificial joints or dental posts, must be perfectly biocompatible. Any surface contamination can cause the human body to reject the implant.

Vacuum heat treatment ensures these components are sterile, pure, and free from any surface oxides, promoting patient safety and device longevity.

Understanding the Trade-offs and Benefits

While incredibly powerful, vacuum furnaces represent a significant investment. Understanding their operational costs and benefits is key to appreciating their value.

The Challenge of Complexity and Cost

Vacuum furnaces are complex machines that require a higher initial investment than traditional atmosphere furnaces. They also involve more sophisticated operation and maintenance procedures.

The Benefit of Energy Efficiency

Modern vacuum furnaces are designed with advanced heating technology and superior insulation. This significantly reduces energy consumption compared to older or conventional methods.

Over time, this improved energy efficiency helps lower production costs and minimize the environmental impact of the manufacturing process.

The Advantage of Process Versatility

A single vacuum furnace can often perform multiple heat treatment processes, such as hardening, annealing, and brazing. This adaptability makes them a flexible and valuable asset in both small-scale research labs and large industrial production facilities.

Making the Right Choice for Your Goal

Deciding to use a vacuum furnace depends entirely on the required quality and performance standards of the final product.

- If your primary focus is material purity and performance: A vacuum furnace is the only way to guarantee a component is free from oxidation and surface contamination.

- If your primary focus is process consistency for high-spec parts: The precise control over the heating and cooling cycles ensures every part meets exacting standards.

- If your primary focus is manufacturing advanced materials: For composites, high-strength alloys, or semiconductors, a vacuum environment is not a choice but a necessity.

Ultimately, investing in vacuum furnace technology is a strategic decision to prioritize material quality and reliability above all else.

Summary Table:

| Feature | Benefit |

|---|---|

| Contamination-free environment | Prevents oxidation and impurities for superior material strength and purity |

| Precise temperature control | Ensures consistent results in heat treatment processes like hardening and annealing |

| Versatile applications | Supports multiple industries including aerospace, electronics, and medical |

| Energy efficiency | Reduces operational costs and environmental impact with advanced insulation |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, Muffle, Tube, and Rotary Furnaces, is complemented by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, electronics, or medical fields, our vacuum furnaces ensure unmatched quality and reliability. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability