At its core, a vacuum environment is critical in a vacuum furnace because it provides an ultra-clean, chemically inert space for processing materials. By pumping out air and other reactive gases like oxygen, the vacuum prevents unwanted chemical reactions such as oxidation and decarburization. This allows for the high-temperature treatment of sensitive materials, ensuring the final product has superior purity, strength, and surface quality.

The primary function of the vacuum is not to create emptiness, but to establish a precisely controlled environment. It removes the reactive elements of air, giving operators complete control over the chemical and thermal conditions of the process.

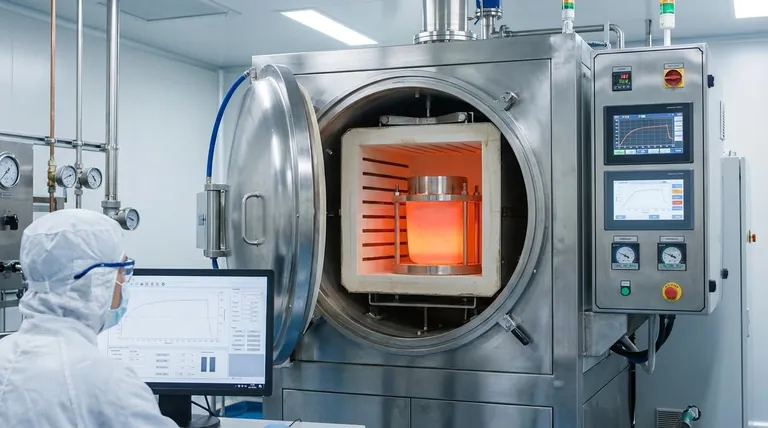

The Three Core Functions of the Vacuum

A vacuum furnace isn't just a hot box; it's a precision instrument. The vacuum itself is the key feature that enables three distinct advantages over conventional atmospheric furnaces.

1. Preventing Contamination and Chemical Reactions

The air we breathe is about 21% oxygen, which is highly reactive at high temperatures. Exposing hot metals to oxygen causes oxidation (rusting or scaling), which creates a brittle, discolored surface layer.

Other reactive gases can cause issues like decarburization, where carbon is stripped from the surface of steel alloys, making them softer and weaker.

A high vacuum removes these reactive gases, creating an inert environment. This ensures the material's surface remains bright and clean, and its fundamental chemistry is unaltered during processing. This is essential for applications like aerospace components, medical implants, and high-purity metals.

2. Enabling Precise Thermal Control

In a traditional furnace, air transfers heat primarily through convection, which can lead to uneven heating as currents circulate within the chamber.

In a vacuum, convection is eliminated. Heat is transferred almost exclusively through radiation from the heating elements to the material. This is a more direct and uniform method of heating, allowing for exceptional temperature consistency across the entire part.

Furthermore, removing air allows for controlled cooling (quenching) by backfilling the chamber with a high-purity inert gas like argon or nitrogen. This provides precise control over the material's final microstructure and mechanical properties.

3. Enhancing Material Properties

Processes like sintering (fusing powdered materials together with heat) and brazing (joining metals with a filler material) benefit immensely from a vacuum.

The vacuum pulls out trapped gases from between the powder particles or at the joint interface. This removal of contaminants and voids results in a denser, stronger final product with superior physical and mechanical integrity.

For advanced materials like refractory alloys (e.g., tungsten, molybdenum) or titanium, processing in a vacuum is not just beneficial—it is often the only way to achieve the required purity and performance characteristics.

Understanding the Trade-offs

While powerful, a vacuum environment is not the default solution for all heating applications. It introduces specific challenges and costs that must be considered.

Slower Heat Transfer Rates

The lack of convection means that radiative heating, while uniform, can be slower than heating in an atmosphere furnace. Processes can take longer, which impacts throughput. This is often mitigated by backfilling with an inert gas to introduce controlled convection once the vacuum has served its primary cleaning purpose.

Complexity and Cost

Vacuum furnaces are complex machines. They require sophisticated pumping systems (roughing pumps and high-vacuum pumps), robust chamber seals, and precise controls. This results in higher initial investment, more rigorous maintenance, and higher operating costs compared to simpler atmospheric furnaces.

The Challenge of Outgassing

Materials, especially those that are porous or have not been properly cleaned, can release trapped gases and vapors when heated. This phenomenon, known as outgassing, can contaminate the vacuum environment and compromise the process. Proper material preparation and adequate pumping capacity are critical to manage it.

Making the Right Choice for Your Application

Selecting the right thermal processing environment depends entirely on your material and your desired outcome.

- If your primary focus is high-purity or reactive materials: A vacuum furnace is essential. It is the standard for processing titanium, refractory metals, and medical-grade alloys.

- If your primary focus is a clean, bright surface finish: Use a vacuum furnace for processes like brazing, annealing, and hardening where post-process cleaning is undesirable.

- If your primary focus is enhanced material density and strength: A vacuum furnace is critical for high-performance sintering and additive manufacturing applications.

- If your primary focus is cost-effective bulk heat treatment: An atmospheric furnace may be sufficient for general-purpose applications where slight surface oxidation is acceptable or can be easily removed.

Ultimately, choosing a vacuum furnace is a decision to prioritize material integrity and environmental control above all else.

Summary Table:

| Function | Key Benefit |

|---|---|

| Preventing Contamination | Eliminates oxidation and decarburization for clean, unaltered surfaces |

| Enabling Precise Thermal Control | Provides uniform heating and controlled cooling via radiation |

| Enhancing Material Properties | Improves density and strength in sintering and brazing processes |

Elevate your material processing with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior purity, strength, and efficiency. Contact us today to discuss how we can optimize your thermal processes and achieve outstanding results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties