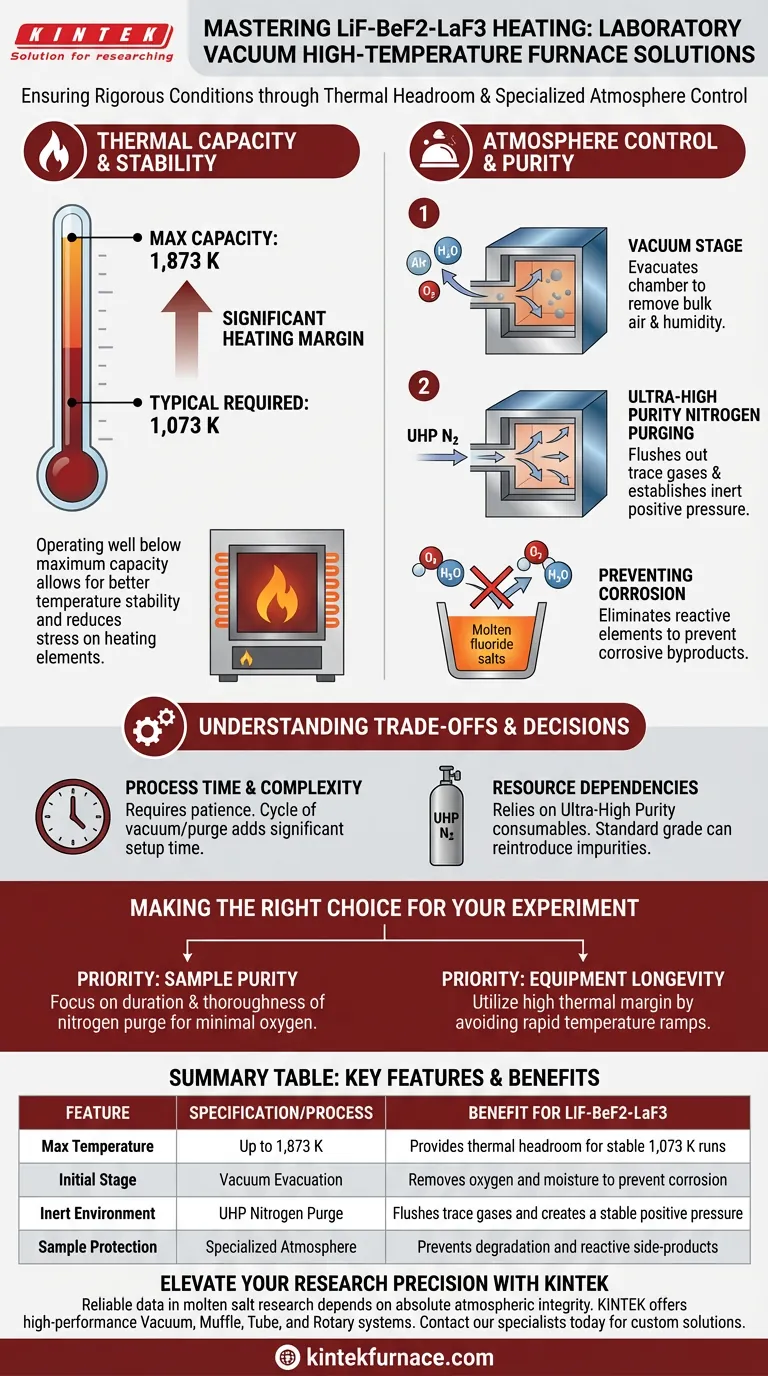

A laboratory vacuum high-temperature furnace ensures rigorous experimental conditions by combining significant thermal headroom with a specialized atmosphere control system. It utilizes a vacuum phase followed by an ultra-high purity nitrogen purge to eliminate environmental contaminants, protecting the LiF-BeF2-LaF3 mixture from degradation.

Success in heating fluoride salt mixtures relies on preventing interaction with the atmosphere. This furnace system mitigates the risk of corrosive side reactions by effectively removing oxygen and moisture before the temperature rises.

Thermal Capacity and Stability

Significant Heating Margin

The furnace is capable of reaching temperatures up to 1,873 K. This provides a substantial performance margin over the 1,073 K typically required for LiF-BeF2-LaF3 experiments.

Consistent Thermal Performance

Operating well below the furnace's maximum capacity allows for better temperature stability. It reduces stress on heating elements, ensuring consistent thermal conditions throughout the duration of the experiment.

Atmosphere Control and Purity

The Vacuum Stage

Before heating begins, the system employs a vacuum mechanism. This step physically evacuates the chamber, removing the bulk of air and ambient humidity that would otherwise react with the sample.

Ultra-High Purity Nitrogen Purging

Following the vacuum stage, the chamber is purged with ultra-high purity nitrogen. This process flushes out any remaining trace gases and establishes an inert positive pressure environment.

Preventing Corrosive Side Reactions

Molten fluoride salts are highly reactive to oxygen and moisture. By eliminating these elements, the furnace prevents the formation of corrosive byproducts that could damage the apparatus or invalidate experimental results.

Understanding the Trade-offs

Process Time and Complexity

Achieving such rigorous conditions requires patience. The cycle of drawing a vacuum and purging with nitrogen adds significant setup time compared to standard atmospheric furnaces.

Resource Dependencies

The system relies heavily on the availability of ultra-high purity consumables. Using standard industrial-grade nitrogen can reintroduce impurities, negating the benefits of the vacuum system.

Making the Right Choice for Your Experiment

To maximize the effectiveness of this furnace setup for your specific goals, consider the following:

- If your primary focus is Sample Purity: Prioritize the duration and thoroughness of the nitrogen purge cycle to ensure absolute minimal oxygen content.

- If your primary focus is Equipment Longevity: Utilize the high thermal margin by avoiding rapid temperature ramps, as the furnace is operating comfortably within its limits.

Reliable data in molten salt research depends entirely on the integrity of your atmospheric control.

Summary Table:

| Feature | Specification/Process | Benefit for LiF-BeF2-LaF3 |

|---|---|---|

| Max Temperature | Up to 1,873 K | Provides thermal headroom for stable 1,073 K runs |

| Initial Stage | Vacuum Evacuation | Removes oxygen and moisture to prevent corrosion |

| Inert Environment | UHP Nitrogen Purge | Flushes trace gases and creates a stable positive pressure |

| Sample Protection | Specialized Atmosphere | Prevents degradation and reactive side-products |

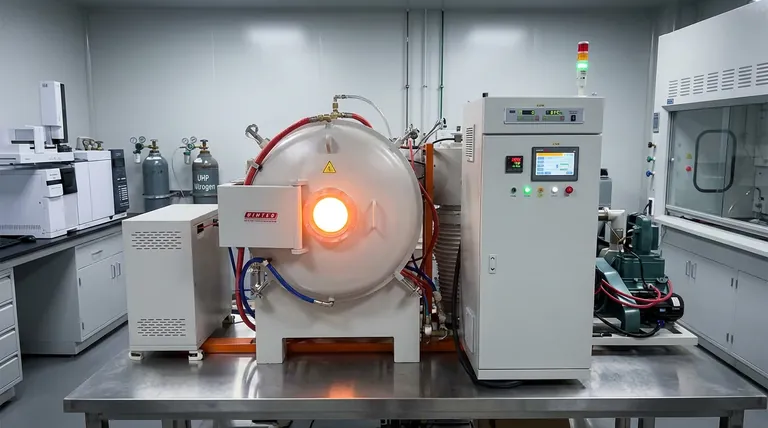

Elevate Your Research Precision with KINTEK

Reliable data in molten salt research depends on absolute atmospheric integrity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and Rotary systems designed to handle the most sensitive experimental conditions. Whether you are heating corrosive fluoride salts or developing advanced materials, our customizable laboratory high-temp furnaces provide the thermal margin and purity control you require.

Ready to optimize your thermal processes? Contact our specialists today to find the perfect furnace solution for your unique laboratory needs.

Visual Guide

References

- Jisue Moon, Theodore M. Besmann. Density Measurements of Molten LiF–BeF<sub>2</sub> and LiF–BeF<sub>2</sub>–LaF<sub>3</sub> Salt Mixtures by Neutron Radiography. DOI: 10.1021/acsomega.4c01446

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the challenges of maintaining a high vacuum in furnaces? Overcome Key Hurdles for Optimal Performance

- What are the advantages of horizontal vacuum furnaces in terms of space and integration? Optimize Your Lab's Layout and Efficiency

- What is the function of a Vacuum or Inert Gas Brazing Furnace? Ensure High-Integrity Energy Equipment Seals

- What technical problems are addressed by using a tempering furnace for bearing steel? Achieve Peak Stability.

- What role does hydrogen play in the operation of a vacuum sintering furnace? Unlock Superior Sintering Quality and Efficiency

- What is the purpose of using a vacuum in a furnace? Prevent Oxidation and Achieve Superior Material Purity

- What are the benefits of using vacuum and controlled environments in sintering furnaces? Achieve Superior Material Quality and Efficiency

- What are the key differences in maximum temperature between low vacuum and high vacuum furnaces? Unlock Higher Heat for Purity