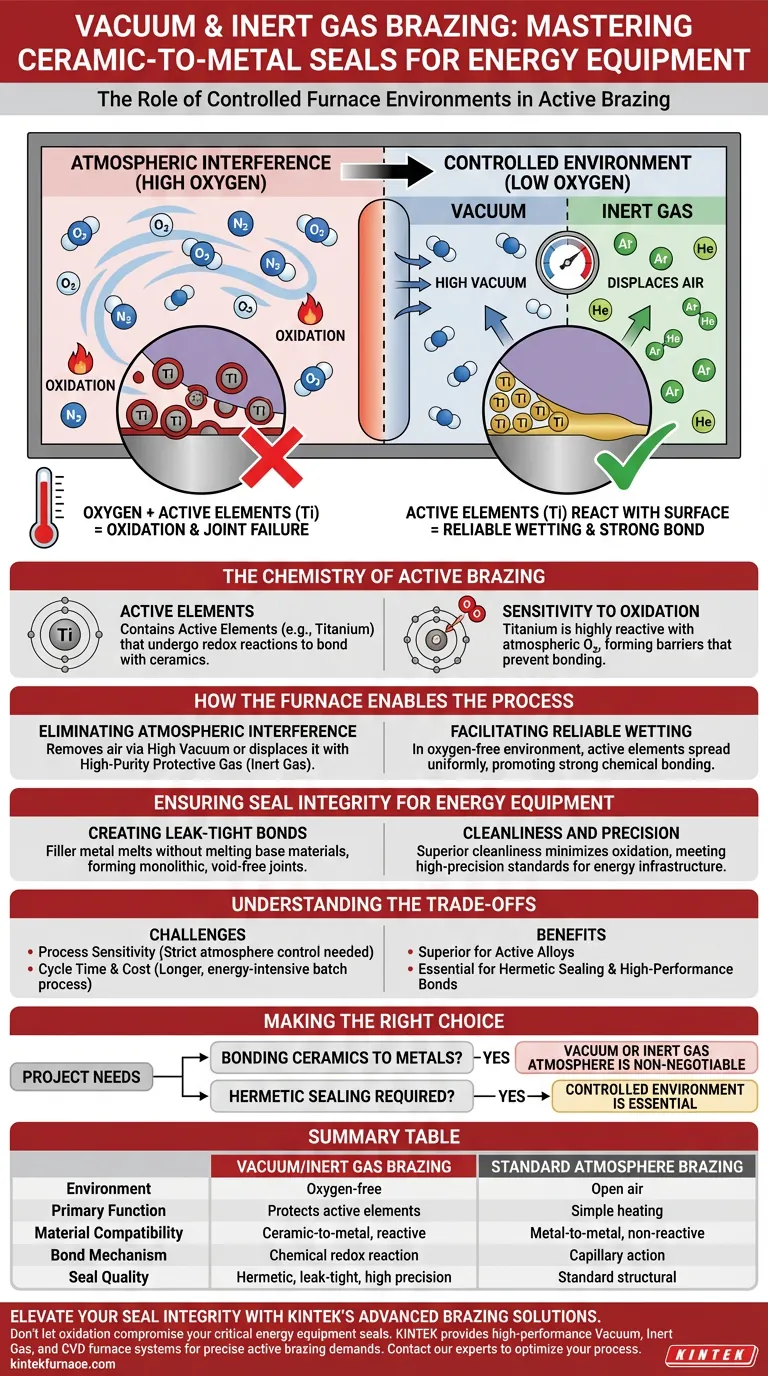

The primary function of a Vacuum or Inert Gas Brazing Furnace is to create a strictly controlled, low-oxygen environment. By either extracting a high vacuum or filling the chamber with high-purity protective gas, the furnace prevents atmospheric oxygen from interfering with the highly reactive chemistry required to bond metals to ceramics.

Core Takeaway Active brazing relies on "active" chemical elements effectively attacking a ceramic surface to create a bond. Because these elements react instantly with oxygen in the air, a specialized furnace environment is mandatory to ensure they react with the component surfaces instead of the atmosphere.

The Chemistry of Active Brazing

To understand the furnace's role, you must first understand the unique requirements of Active Brazing Alloys (ABA).

The Role of Active Elements

Standard brazing relies on capillary action, but active brazing uses chemical reactions.

ABAs contain "active" elements, most notably titanium (Ti). These elements are designed to undergo redox reactions with ceramic surfaces, facilitating a bond where one normally wouldn't exist.

The Sensitivity to Oxidation

The strength of titanium is also its weakness in processing: it is highly reactive with atmospheric oxygen.

If oxygen is present in the furnace chamber, the titanium will scavenge it and oxidize immediately. This creates a barrier that prevents the alloy from interacting with the base materials, leading to joint failure.

How the Furnace Enables the Process

The furnace acts as a shield, preserving the chemical potential of the brazing alloy.

Eliminating Atmospheric Interference

The furnace removes air to an extreme degree.

By creating a high vacuum, the system physically extracts oxygen molecules that would otherwise contaminate the process. Alternatively, the chamber can be filled with a high-purity protective gas (inert gas) to displace the air.

Facilitating Reliable Wetting

Once the oxygen is removed, the active elements are free to do their job.

In this protected environment, the titanium can successfully react with the ceramic surface. This reaction promotes wetting—the ability of the molten filler metal to spread uniformly across the surface—which is the prerequisite for a strong bond.

Ensuring Seal Integrity for Energy Equipment

For energy equipment, the stakes for seal failure are often high.

Creating Leak-Tight Bonds

Energy equipment seals often require hermetic integrity.

Furnace brazing ensures that the filler metal melts without melting the base materials, creating a monolithic, leak-tight joint. The controlled environment minimizes voids and inclusions that could lead to leaks.

Cleanliness and Precision

Vacuum and inert gas furnaces provide superior cleanliness compared to open-air methods.

This minimizes oxidation on the finished part, ensuring the final assembly meets the high-precision standards required for sophisticated energy infrastructure.

Understanding the Trade-offs

While vacuum or inert gas brazing is superior for active alloys, it presents specific operational challenges.

Process Sensitivity

The process leaves little room for error regarding atmosphere purity.

Even a minor leak in the vacuum system or contaminants in the inert gas supply can compromise the titanium, resulting in a failed batch. Strict maintenance of the furnace atmosphere is required.

Cycle Time and Cost

These furnaces operate as batch processes with significant cycle times.

Heating a chamber under vacuum and cooling it down requires more time and energy than continuous atmospheric brazing, representing a higher cost per part that is justified only by the need for high-performance ceramic-to-metal bonds.

Making the Right Choice for Your Project

The decision to use this specific equipment is driven by the materials you are joining.

- If your primary focus is bonding ceramics to metals: The vacuum or inert gas atmosphere is non-negotiable to prevent the active elements (like Titanium) from oxidizing before they bond.

- If your primary focus is hermetic sealing: The controlled environment is essential to create void-free, leak-tight joints required for energy applications.

Ultimately, the furnace is not just a heat source; it is a chemical reaction vessel that makes active brazing physically possible.

Summary Table:

| Feature | Vacuum/Inert Gas Brazing | Standard Atmosphere Brazing |

|---|---|---|

| Environment | Oxygen-free (High vacuum or inert gas) | Open air or standard atmosphere |

| Primary Function | Protects active elements (Ti) from oxidation | Simple heating of filler metals |

| Material Compatibility | Ceramic-to-metal, reactive alloys | Metal-to-metal, non-reactive alloys |

| Bond Mechanism | Chemical redox reaction (Wetting) | Capillary action |

| Seal Quality | Hermetic, leak-tight, high precision | Standard structural bonding |

Elevate Your Seal Integrity with KINTEK’s Advanced Brazing Solutions

Don't let oxidation compromise your critical energy equipment seals. At KINTEK, we specialize in providing high-performance Vacuum, Inert Gas, and CVD furnace systems designed for the precise demands of active brazing. Backed by expert R&D and world-class manufacturing, our customizable high-temperature furnaces ensure the reliable wetting and hermetic bonding required for your unique ceramic-to-metal applications.

Ready to optimize your brazing process? Contact our engineering experts today to discover how KINTEK’s precision equipment can enhance your lab’s efficiency and product reliability.

Visual Guide

References

- Jian Feng, Antonio Hurtado. Active Brazing for Energy Devices Sealing. DOI: 10.3390/jeta2010001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the regulatory function of a vacuum drying oven? Master Catalyst Preparation and Distribution Control

- Why are cooling systems necessary in vacuum furnaces? Essential for Material Control and Equipment Protection

- What role does a vacuum system play in Vanadium-Nitrogen alloy preparation? Boost Chemical Efficiency and Yield

- What are the benefits of custom-designed vacuum furnaces in advanced manufacturing? Achieve Precision and Efficiency in Your Processes

- What temperature range is used in vacuum brazing? Achieve Strong, Flux-Free Metal Joints

- What are the main functions of an annealing furnace? Achieve Precise Material Control and Enhanced Performance

- What benefits does a Vacuum Oven offer for silica-based anode coatings? Enhance Battery Coulombic Efficiency

- How is a laboratory vacuum drying oven utilized in the production of shape-stabilized phase change materials?