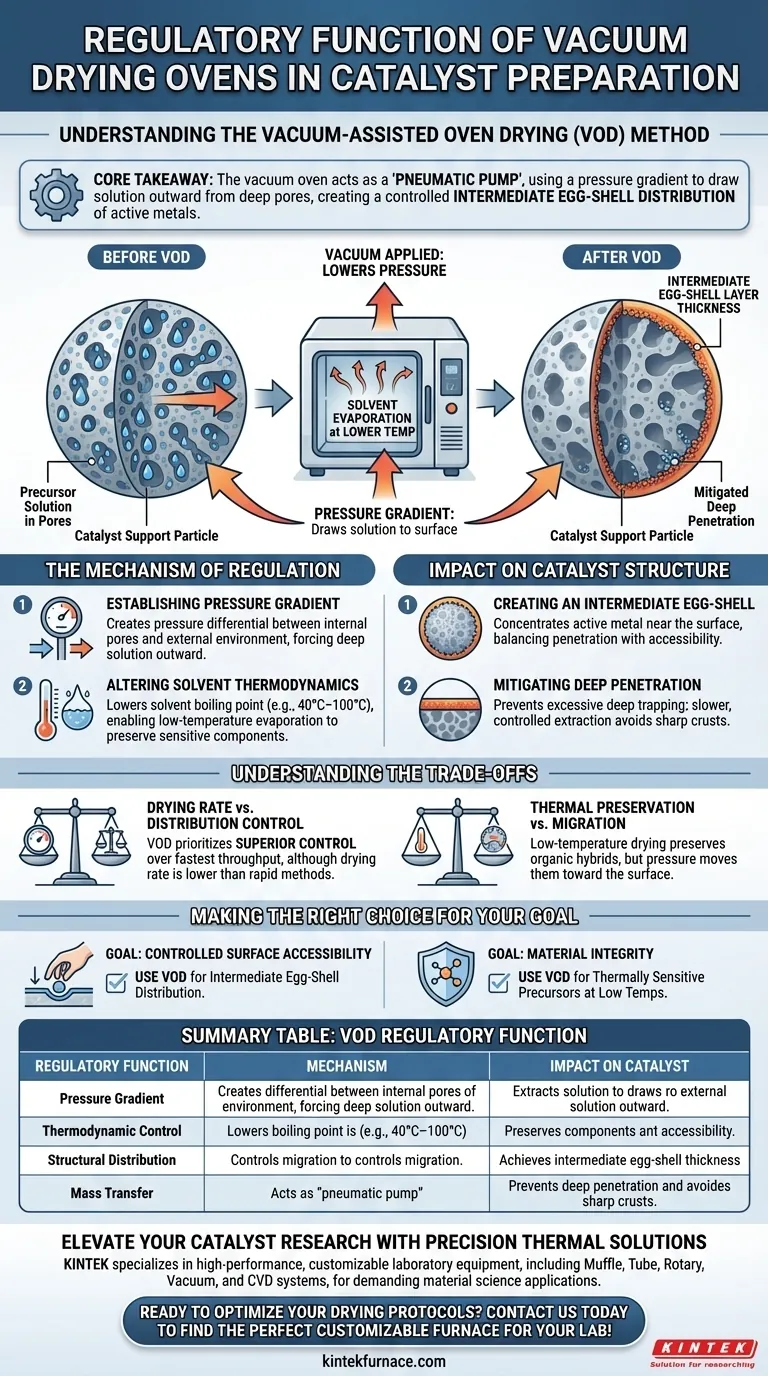

The regulatory function of a vacuum drying oven in the Vacuum-assisted Oven Drying (VOD) method is to manipulate the distribution of active components by creating a specific pressure gradient.

By lowering the system pressure, the oven reduces the solvent's boiling point and generates a pressure differential that physically extracts a portion of the precursor solution from the internal pores of the catalyst support. This process regulates the depth of component penetration, resulting in an intermediate egg-shell layer thickness—placing the catalyst structure between that of standard oven drying and rapid convective drying.

Core Takeaway The vacuum drying oven acts as a "pneumatic pump" during drying; rather than simply evaporating solvent in place, it uses a pressure gradient to draw solution outward from deep pores. This creates a controlled, intermediate distribution of active metals near the surface (egg-shell), balancing deep penetration with surface accessibility.

The Mechanism of Regulation

Establishing the Pressure Gradient

The primary regulatory mechanism is the creation of a pressure differential between the interior of the catalyst pores and the external environment.

Unlike standard drying, which relies on capillary forces or diffusion, VOD lowers the external pressure significantly. This forces the solution residing deep within the internal pores to move outward toward the surface.

Altering Solvent Thermodynamics

The vacuum environment directly regulates the thermal dynamics of the drying process.

By reducing the system pressure, the boiling point of the solvent (often water or organic solvents) is lowered. This allows evaporation to occur at much lower temperatures (e.g., 40°C to 100°C), preserving the integrity of thermally sensitive components while facilitating the physical extraction of the solution.

Impact on Catalyst Structure

Creating an Intermediate Egg-Shell

The defining outcome of this regulatory function is the structural distribution of the active metal.

Because the pressure gradient pulls some—but not all—of the solution to the surface, the resulting distribution is an "intermediate egg-shell." This means the active components are concentrated near the outer shell of the support, but the layer is not as thin or concentrated as it would be with rapid convective drying, nor as deeply distributed as with standard uniform drying.

Mitigating Deep Penetration

The VOD method specifically functions to prevent the active components from being trapped too deeply within the support.

While the low-pressure environment mitigates deep penetration, the drying rate is generally lower than "quick drying" methods. This slower, controlled extraction prevents the formation of an excessively sharp or thin crust, leading to the "intermediate" characteristic described above.

Understanding the Trade-offs

Drying Rate vs. Distribution Control

A common misconception is that vacuum drying is purely for speed; however, its primary value here is distribution control.

While it lowers boiling points, the actual drying rate in VOD is typically lower than rapid convective drying methods. If your goal is purely the fastest possible throughput, VOD may be a bottleneck compared to high-heat rapid drying, even though it offers superior control over the metal profile.

Thermal Preservation vs. Migration

While the primary function is structural regulation via pressure, a critical side effect is thermal protection.

For organic-inorganic hybrid precursors, the ability to dry at lower temperatures prevents oxidation and deterioration. However, one must balance this against the pressure-induced migration; you are preserving the chemical nature of the precursor, but you are effectively moving it toward the surface of the support.

Making the Right Choice for Your Goal

To determine if the Vacuum-assisted Oven Drying (VOD) method aligns with your manufacturing requirements, evaluate your targets against the method's regulatory mechanics.

- If your primary focus is Controlled Surface Accessibility: Use VOD to achieve an intermediate egg-shell distribution, concentrating active sites near the surface without creating an overly dense or brittle crust.

- If your primary focus is Material Integrity: Use VOD to process thermally sensitive precursors (like organic hybrids) at low temperatures (40°C–100°C) to prevent oxidation or structural collapse.

Ultimately, the vacuum drying oven serves not just as a dryer, but as a mass-transfer tool that uses pressure to fine-tune the location of active metals within the catalyst support.

Summary Table:

| Regulatory Function | Mechanism | Impact on Catalyst |

|---|---|---|

| Pressure Gradient | Creates differential between internal pores and environment | Extracts solution from deep pores to the surface |

| Thermodynamic Control | Lowers solvent boiling point (40°C - 100°C) | Preserves thermally sensitive components |

| Structural Distribution | Controls liquid migration speed and depth | Achieves precise intermediate egg-shell thickness |

| Mass Transfer | Acts as a "pneumatic pump" | Prevents deep penetration of active sites |

Elevate Your Catalyst Research with Precision Thermal Solutions

Achieving the perfect active metal distribution requires precise control over pressure and temperature. At KINTEK, we specialize in providing high-performance laboratory equipment designed for the most demanding material science applications.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique catalyst preparation needs. Whether you are aiming for specific egg-shell thickness or processing thermally sensitive organic-inorganic hybrids, our vacuum ovens provide the stability and control your research demands.

Ready to optimize your drying protocols? Contact us today to find the perfect customizable furnace for your lab!

Visual Guide

References

- Eun-Han Lee, Shin‐Kun Ryi. Quick drying process: a promising strategy for preparing an egg-shell-type Cu/γ-Al <sub>2</sub> O <sub>3</sub> catalyst for direct N <sub>2</sub> O decomposition. DOI: 10.1039/d4ta07764d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the advantages of using a vacuum drying oven for t-BTO nanoparticles? Preserve Critical Material Integrity

- What components are used in the construction of vacuum graphitizing furnaces? A Guide to High-Temp Performance

- What is the difference between heat treat and vacuum heat treat? Achieve Superior Metal Properties with Pristine Finishes

- What industries benefit from High Vacuum Melting Furnaces? Unlock Purity for Aerospace, Biomedical & More

- What improvements in mechanical properties can be achieved using a vacuum furnace? Boost Strength, Toughness, and Fatigue Life

- What processes are performed in a high-temperature vacuum furnace? Achieve Purity and Precision in Material Processing

- Can horizontal vacuum furnaces be customized for specific needs? Tailor Your Thermal Process for Optimal Results

- What role does rotary mechanical stirring play in the high-temperature synthesis of mesophase pitch? Maximize Homogeneity