Yes, absolutely. Horizontal vacuum furnaces can be, and frequently are, customized to meet highly specific operational needs. While standard models exist for common applications, projects that are experimental, involve unique materials, or require atypical process parameters often necessitate a tailored solution designed in close collaboration with engineering experts.

The ability to customize a vacuum furnace goes far beyond simple dimensional changes. True customization is about engineering the core thermal process—from heating and cooling rates to vacuum levels—to perfectly match your material and production goals, ensuring optimal results and efficiency.

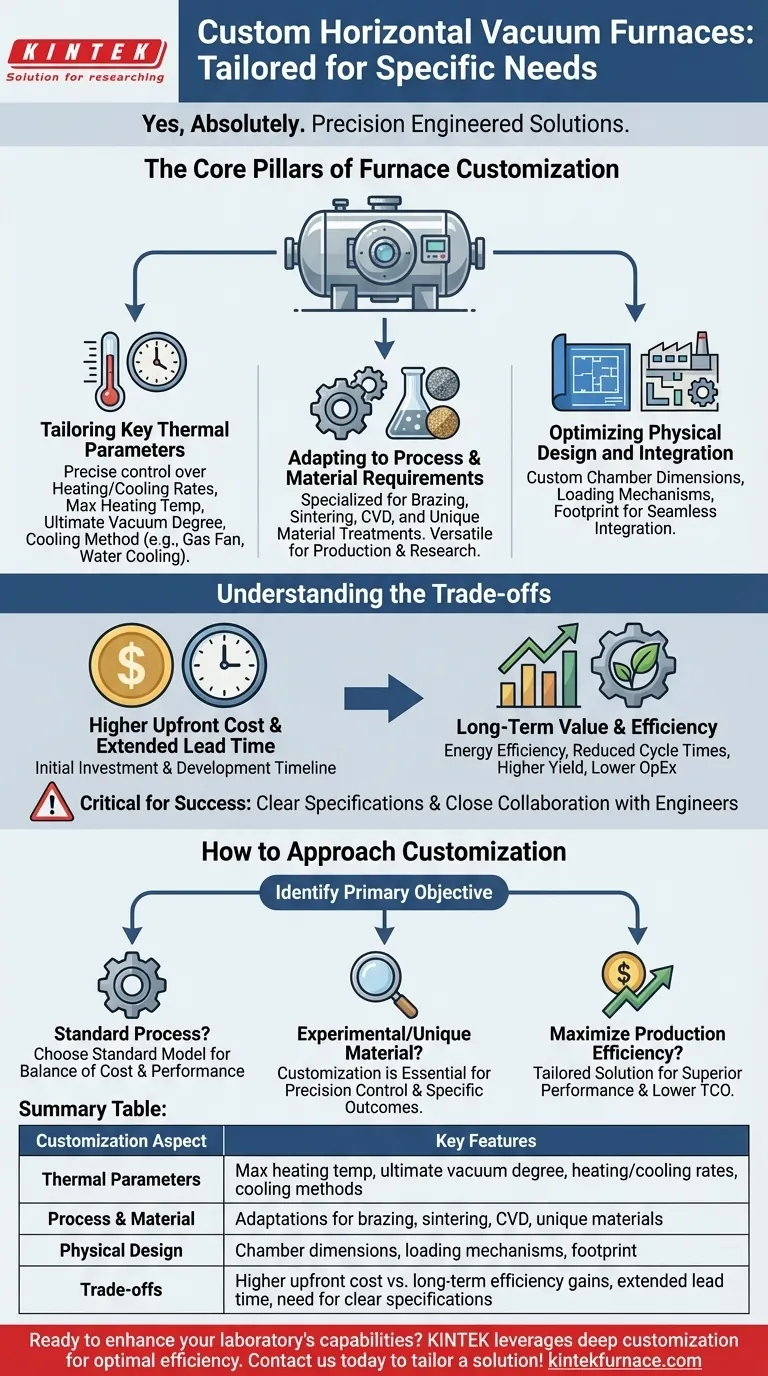

The Core Pillars of Furnace Customization

Understanding what can be modified is the first step in determining if a custom solution is right for you. Customization revolves around adapting the furnace's key operational parameters and physical characteristics to a specific process.

Tailoring Key Thermal Parameters

The heart of any furnace is its ability to control the thermal environment. Customization allows for precise engineering of these critical variables.

This includes specifying the maximum heating temperature, the required ultimate vacuum degree, the precise heating and cooling rates, and the cooling method (e.g., gas fan, water cooling).

Adapting to Process & Material Requirements

Different processes, such as brazing, sintering, or chemical vapor deposition (CVD), have unique demands. Likewise, special materials require specific treatment protocols.

A custom furnace can be designed to handle these unique needs, ensuring the system is a versatile and effective tool for both industrial production and advanced research.

Optimizing the Physical Design and Integration

Customization isn't limited to internal performance. The furnace must also fit within your facility and workflow.

This can involve modifying the chamber dimensions, loading mechanisms, and overall footprint to seamlessly integrate into your existing production line and material handling processes.

Understanding the Trade-offs

While customization offers significant advantages, it's essential to approach it with a clear understanding of the associated trade-offs.

Cost vs. Long-Term Value

A bespoke furnace will have a higher upfront investment compared to a standard, off-the-shelf model.

However, this initial cost can be offset by long-term gains in energy efficiency, reduced cycle times, higher product yield, and lower operational expenses, as mentioned in the references regarding advanced heating and insulation.

Lead Time and Development

Designing and manufacturing a custom system is an intensive process that requires more time than purchasing a standard unit.

This extended lead time must be factored into your project timeline. The process involves close collaboration, design reviews, and fabrication, all of which contribute to the delivery schedule.

The Need for a Clear Specification

The success of a custom furnace depends entirely on the quality of the initial requirements. Ambiguity can lead to a solution that doesn't fully meet expectations.

Working closely with the manufacturer's engineers to clearly define every aspect of your process is not just recommended—it is critical for success.

How to Approach Customization

Deciding between a standard and custom furnace requires evaluating your primary objective.

- If your primary focus is a standard, well-defined process: A standard furnace model will likely provide the most effective balance of cost, performance, and availability.

- If your primary focus is experimental research or a unique material: Customization is essential to precisely control variables and achieve the specific outcomes your work demands.

- If your primary focus is maximizing long-term production efficiency: A tailored furnace, engineered for your specific workflow, can deliver superior performance and a lower total cost of ownership over its lifespan.

Ultimately, choosing the right vacuum furnace is a strategic decision that directly impacts the quality and efficiency of your operations.

Summary Table:

| Customization Aspect | Key Features |

|---|---|

| Thermal Parameters | Max heating temperature, ultimate vacuum degree, heating/cooling rates, cooling methods (e.g., gas fan, water cooling) |

| Process & Material | Adaptations for brazing, sintering, CVD, and unique material treatments |

| Physical Design | Chamber dimensions, loading mechanisms, footprint for seamless integration |

| Trade-offs | Higher upfront cost vs. long-term efficiency gains, extended lead time, need for clear specifications |

Ready to enhance your laboratory's capabilities with a custom high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With strong deep customization, we precisely meet your unique experimental needs for optimal efficiency and results. Contact us today to discuss how we can tailor a solution for you!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability