In short, high vacuum melting furnaces are indispensable for industries that demand the highest possible material purity and performance. The primary beneficiaries are aerospace, biomedical, energy, and advanced electronics, where even microscopic impurities can lead to catastrophic failure. These furnaces solve the fundamental problem of atmospheric contamination during the melting process.

The critical takeaway is not just which industries use these furnaces, but why. Standard melting exposes liquid metal to oxygen and nitrogen, creating impurities that weaken the final product. A high vacuum environment removes these reactive gases, enabling the creation of ultra-pure metals and complex superalloys that are simply impossible to produce otherwise.

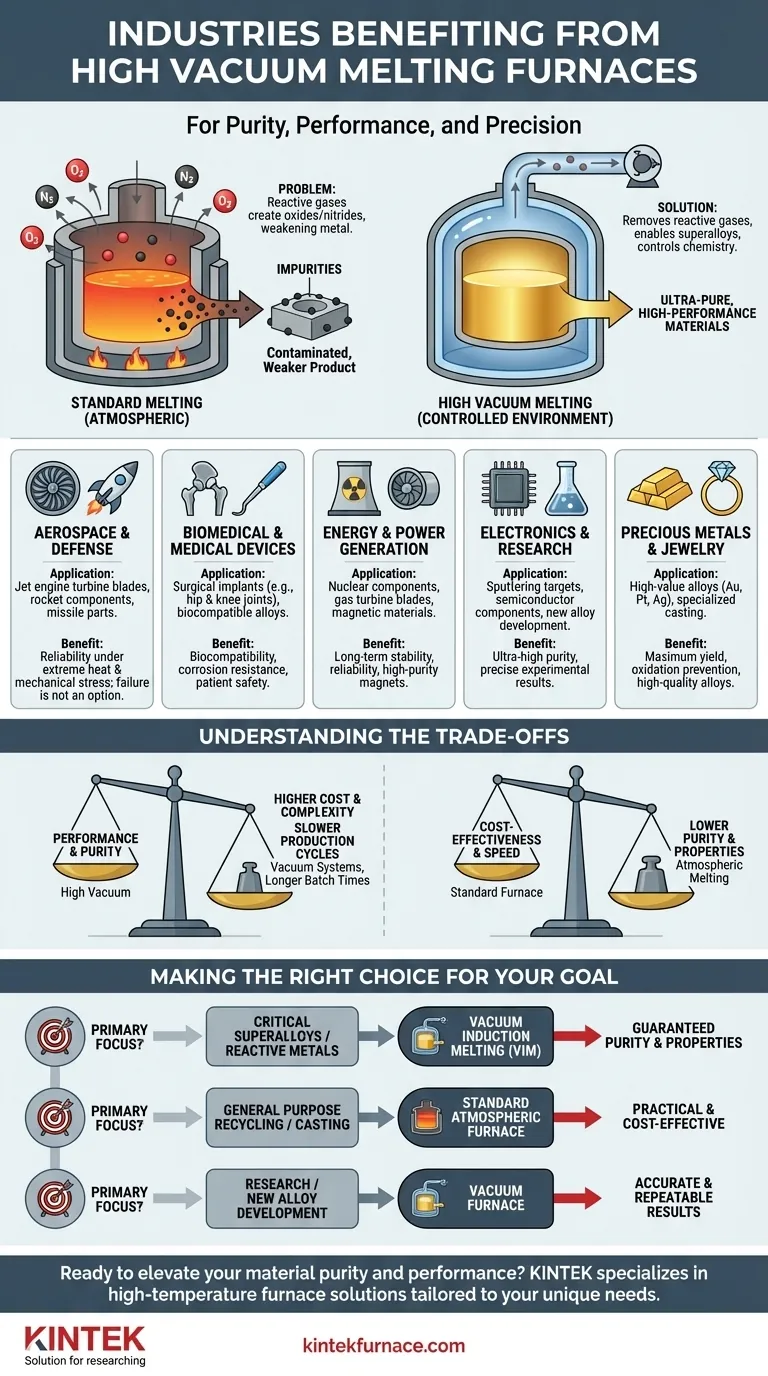

The Core Problem: Why Vacuum is Non-Negotiable

A high vacuum furnace isn't just an oven; it's a controlled environment designed to solve a fundamental metallurgical challenge: contamination.

Eliminating Atmospheric Contamination

When metals are melted in open air, they aggressively react with oxygen and nitrogen. This creates oxides and nitrides, which are essentially metallic "rust" that gets trapped in the final product.

A vacuum furnace pumps out these reactive gases before melting begins, creating a clean environment. This prevents the formation of these impurities from the start.

The Impact of Unwanted Impurities

Impurities act as weak points within the metal's crystal structure. They can drastically reduce critical properties like strength, ductility, and corrosion resistance, making the material unreliable for high-stress applications.

Controlling Volatile Elements

A vacuum also provides precise control over the alloy's final chemistry. It can be used to boil off and remove undesirable, volatile elements (like lead or cadmium). Conversely, by backfilling with an inert gas like argon, it helps retain beneficial volatile elements required for the alloy's properties.

Key Industries and Their Critical Applications

The need for this level of control and purity directly drives adoption in several high-stakes fields.

Aerospace and Defense

This sector relies on superalloys (nickel or cobalt-based) for jet engine turbine blades, rocket components, and missile parts. These components must operate reliably under extreme heat and mechanical stress, where material failure is not an option.

Biomedical and Medical Devices

Purity is a matter of patient safety. Vacuum furnaces are used to produce highly biocompatible and corrosion-resistant materials like titanium and cobalt-chrome alloys for surgical implants (e.g., hip and knee joints), where any reaction with the human body must be avoided.

Energy and Power Generation

From components in nuclear reactors to blades in high-efficiency gas turbines, the energy sector demands materials with long-term stability and reliability. Vacuum melting is also used to create powerful, high-purity magnetic materials essential for modern power generators.

Electronics and Research

The electronics industry requires ultra-high purity metals for creating sputtering targets (used to deposit thin films on semiconductors) and other sensitive components. For researchers, vacuum furnaces provide the ultimate controlled environment for new alloy development, ensuring experimental results are precise and repeatable.

Precious Metals and Jewelry

When working with high-value materials like gold, platinum, and silver, preventing any material loss through oxidation is a financial imperative. Vacuum melting ensures maximum yield and purity, and it allows for the creation of specialized, high-quality alloys.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every melting task.

Higher Cost and Complexity

Vacuum systems add significant cost and mechanical complexity compared to standard atmospheric furnaces. They require robust vacuum pumps, seals, and control systems, along with specialized operator training.

Slower Production Cycles

The process of pumping the chamber down to a deep vacuum takes time. This makes the batch cycle time for a vacuum furnace inherently longer than that of a simple air-melt furnace, impacting overall throughput.

When Is It Overkill?

For many common applications—such as producing standard structural steel, cast iron parts, or aluminum components where minor impurities don't compromise performance—the expense and lower speed of a vacuum furnace are not justified. A conventional induction or arc furnace is far more cost-effective.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on the requirements of your final product.

- If your primary focus is performance-critical superalloys or reactive metals: A vacuum induction melting (VIM) furnace is the only way to guarantee the necessary chemical purity and mechanical properties.

- If your primary focus is casting high-purity precious metals or specialty alloys: A vacuum furnace is essential to prevent oxidation, maximize material yield, and ensure final product quality.

- If your primary focus is general-purpose metal recycling or casting: A standard atmospheric induction furnace is almost always the more practical and cost-effective choice.

- If your primary focus is research and new alloy development: The pristine, controlled environment of a vacuum furnace is indispensable for achieving accurate and repeatable results.

Ultimately, choosing to use a vacuum furnace is a strategic decision to master the very chemistry of your material.

Summary Table:

| Industry | Key Applications | Benefits |

|---|---|---|

| Aerospace & Defense | Jet engine turbine blades, rocket components | High strength, reliability under extreme stress |

| Biomedical & Medical Devices | Surgical implants (e.g., hip joints) | Biocompatibility, corrosion resistance |

| Energy & Power Generation | Nuclear reactor parts, gas turbine blades | Long-term stability, high-purity magnetic materials |

| Electronics & Research | Sputtering targets, new alloy development | Ultra-high purity, precise experimental results |

| Precious Metals & Jewelry | Gold, platinum alloys | Maximum yield, purity, specialized alloys |

Ready to elevate your material purity and performance? At KINTEK, we specialize in high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer advanced options like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, with deep customization to meet precise experimental requirements. Whether you're in aerospace, biomedical, energy, or electronics, our expertise ensures reliable, contamination-free melting. Contact us today to discuss how we can support your high-stakes applications!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity