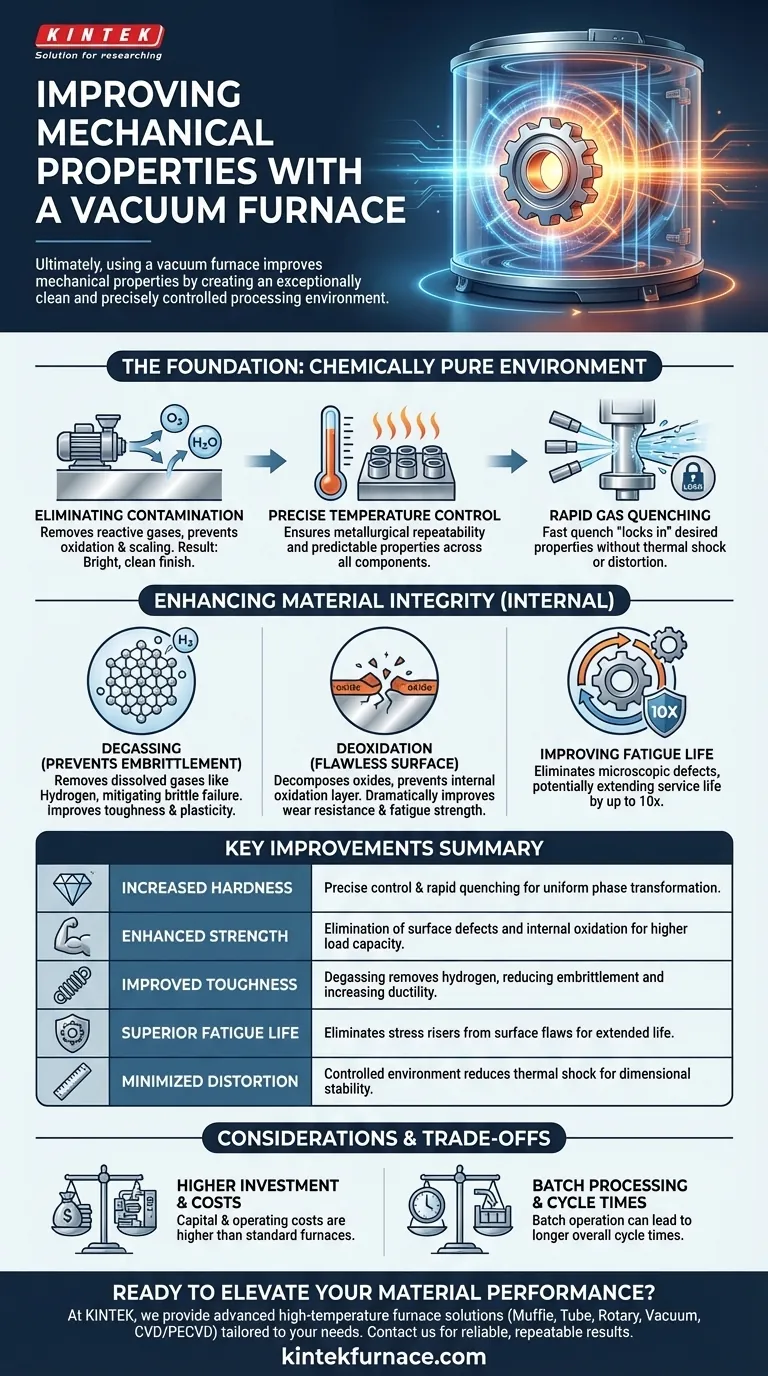

Ultimately, using a vacuum furnace improves mechanical properties by creating an exceptionally clean and precisely controlled processing environment. This allows for heat treatments that yield parts with superior hardness, strength, toughness, and fatigue life. Crucially, these enhancements are achieved while minimizing the distortion and surface defects common in traditional atmospheric furnaces.

The core advantage of a vacuum furnace is not just heat, but control. By removing reactive gases like oxygen and hydrogen, it allows thermal processes to enhance a material's intrinsic properties without introducing new flaws, resulting in cleaner, stronger, and more reliable components.

The Foundation: A Chemically Pure Environment

The primary function of the vacuum is to remove the atmosphere, which is full of reactive elements that can harm metal at high temperatures. This creates an ideal state for heat treatment.

Eliminating Atmospheric Contamination

A vacuum furnace acts like a pristine cleanroom for metal. It pumps out oxygen, water vapor, and other gases that cause oxidation and scaling on the material's surface during heating.

This prevention of surface reactions is critical. It results in a bright, clean finish that requires no subsequent cleaning and ensures the surface metallurgy is not compromised.

The Role of Precise Temperature Control

Modern vacuum furnaces provide exceptionally uniform and accurate temperature control. This precision ensures that the entire part, or an entire batch of parts, experiences the exact same thermal cycle.

This level of control guarantees metallurgical repeatability. Every component achieves the desired microstructure and, therefore, the same predictable mechanical properties, which is vital for critical applications.

The Advantage of Rapid Cooling (Quenching)

Many vacuum furnaces are equipped with high-pressure gas quenching systems. This allows for rapid, controlled cooling after the heating cycle is complete.

This fast quench "locks in" the desired properties, such as high hardness, by controlling the material's phase transformation without the thermal shock and distortion associated with liquid quenching.

How Vacuum Directly Enhances Material Integrity

Beyond simply preventing surface reactions, the vacuum environment actively purifies the metal, leading to significant improvements in its bulk properties.

Degassing to Prevent Embrittlement

At high temperatures, a vacuum effectively pulls dissolved gases out of the metal itself. One of the most important gases removed is hydrogen.

Removing hydrogen mitigates the risk of hydrogen embrittlement, a phenomenon that can cause catastrophic, brittle failure in high-strength materials. The result is a component with significantly improved toughness and plasticity.

Deoxidation for a Flawless Surface Layer

The vacuum can be powerful enough to decompose existing oxides on the metal's surface. The liberated oxygen is then pumped out of the chamber.

This process, combined with specialized techniques like vacuum carburizing, prevents the formation of an "internal oxidation" layer just below the surface. This flaw-free surface dramatically improves the part's wear resistance and fatigue strength.

Improving Fatigue Strength and Overall Life

The combination of a clean surface, no internal oxidation, and reduced embrittlement leads to a substantial increase in fatigue life.

By eliminating the microscopic surface and subsurface defects that act as stress risers, vacuum heat treatment can allow a component's service life to be doubled or even increased tenfold.

Understanding the Trade-offs and Considerations

While the benefits are significant, a vacuum furnace is not a universal solution. Its advantages come with practical trade-offs that must be evaluated.

Higher Initial Investment and Operating Costs

Vacuum furnaces are complex machines with high capital costs compared to standard atmospheric furnaces. Their operation, including energy consumption and maintenance of vacuum pumps, is also more expensive.

Batch Processing and Cycle Times

Most vacuum furnaces operate in batches, which can limit throughput compared to continuous atmospheric furnaces. The time required to pump down to vacuum, run the thermal cycle, and cool the load can lead to longer overall cycle times.

Material and Process Specificity

The benefits of vacuum treatment are most pronounced for specific alloys and applications where purity, surface integrity, and dimensional control are paramount. For simple, low-cost parts with wide tolerances, the expense may not be justifiable.

Making the Right Choice for Your Application

Selecting the right heat treatment process depends entirely on the performance requirements and economic realities of your component.

- If your primary focus is maximum fatigue life and toughness: Vacuum treatment is the superior choice due to its ability to remove hydrogen and prevent internal oxidation.

- If your primary focus is dimensional stability and surface finish: The low distortion and clean, bright finish from vacuum processing are ideal for precision components like gears, bearings, and molds.

- If your primary focus is process repeatability for critical components: The computer-controlled, stable environment of a vacuum furnace delivers unmatched consistency from batch to batch.

By understanding these principles, you can confidently determine when the investment in vacuum heat treatment is essential for achieving your material performance goals.

Summary Table:

| Improvement | Description |

|---|---|

| Increased Hardness | Achieved via precise temperature control and rapid gas quenching for uniform phase transformation. |

| Enhanced Strength | Results from elimination of surface defects and internal oxidation, improving load-bearing capacity. |

| Improved Toughness | Due to degassing that removes hydrogen, reducing embrittlement and increasing ductility. |

| Superior Fatigue Life | Eliminates stress risers from surface flaws, potentially extending service life by up to 10x. |

| Minimized Distortion | Controlled environment reduces thermal shock, ensuring dimensional stability and fewer defects. |

Ready to elevate your material performance with precision heat treatment? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're aiming for superior hardness, strength, or fatigue resistance in critical components, our vacuum furnaces deliver reliable, repeatable results. Contact us today to discuss how we can enhance your lab's efficiency and achieve your material goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance