The fundamental difference between conventional heat treatment and vacuum heat treatment is the environment in which the metal is heated. Conventional methods expose the material to atmospheric air during the heating cycle. Vacuum heat treatment, in contrast, takes place inside a sealed chamber where a pump has removed the air, creating a controlled, contamination-free environment.

The choice between these two methods comes down to a single principle: control. While conventional heat treatment is a straightforward process, it exposes metal to reactive gases in the air. Vacuum heat treatment eliminates these variables, preventing unwanted surface reactions and providing superior control over the final material properties.

How the Environment Changes Everything

The atmosphere, or lack thereof, is the defining factor that separates these two processes and dictates their outcomes.

Conventional Heat Treatment: The Open-Air Approach

In conventional heat treatment, parts are heated in furnaces that operate in the presence of atmospheric air. This air contains approximately 21% oxygen, along with nitrogen and other trace gases.

When steel and other alloys are heated to high temperatures in this environment, the oxygen reacts with the surface of the metal. This chemical reaction is known as oxidation, which forms a dark, flaky layer of scale.

Vacuum Heat Treatment: The Controlled Chamber

Vacuum heat treatment places the parts in a sealed furnace, and a powerful pump system removes the air before heating begins. This creates a low-pressure, near-vacuum environment.

By eliminating the oxygen and other reactive gases, there is nothing for the hot metal surface to react with. This completely prevents oxidation and other atmospheric contamination during the entire process.

The Impact on Process and Results

This difference in environment has profound implications for the quality, consistency, and finish of the final product.

Preventing Oxidation and Decarburization

The most significant advantage of the vacuum environment is the prevention of surface reactions. Without oxygen, no scale can form on the part's surface.

Furthermore, it prevents decarburization—a critical issue for high-carbon steels. In a conventional furnace, reactive gases can strip carbon from the surface layer of the steel, leaving it softer and reducing its wear resistance. A vacuum completely prevents this.

Achieving a Bright, Clean Finish

Because oxidation is eliminated, parts that undergo vacuum heat treatment emerge from the furnace with a clean and bright surface.

This often eliminates the need for post-treatment cleaning operations like sandblasting or chemical pickling, saving time and cost while preserving the component's precise dimensions.

Unmatched Process Control

Vacuum furnaces offer a highly controlled, convection-free environment. Heating is typically done with resistive elements that allow for extremely precise and uniform temperature management.

This level of control ensures highly predictable and repeatable results from one batch to the next, which is critical for high-performance applications in industries like aerospace, medical, and high-end tool manufacturing.

Understanding the Trade-offs

While vacuum heat treatment offers superior results, it is not always the necessary or most economical choice.

The Cost and Complexity Factor

Vacuum furnaces are more complex and have a higher initial investment and operating cost than conventional atmospheric furnaces.

The process cycle can also be longer due to the time required to pump the air out of the chamber before the heating cycle can begin.

When Conventional Is the Right Tool

For many general-purpose applications, conventional heat treatment is perfectly adequate and more cost-effective.

If a component's surface finish is not a critical concern or if it will be machined after heat treatment anyway, the scale produced by atmospheric heating is often acceptable.

Making the Right Choice for Your Material

Your specific goal for the component should guide your decision.

- If your primary focus is cost-effectiveness on low-alloy steels or non-critical parts: Conventional heat treatment is the most practical and economical choice.

- If your primary focus is a pristine surface finish to avoid secondary cleaning: Vacuum heat treatment is the superior method, as it delivers clean, bright parts directly from the furnace.

- If your primary focus is maximizing the performance of tool steels, stainless steels, or aerospace alloys: The precise control and prevention of decarburization offered by a vacuum process are essential.

By understanding the role of the atmosphere in the process, you can select the method that best aligns with your material, budget, and performance requirements.

Summary Table:

| Feature | Conventional Heat Treat | Vacuum Heat Treat |

|---|---|---|

| Process Environment | Open-air furnace with atmospheric gases | Sealed, low-pressure vacuum chamber |

| Surface Outcome | Oxidation and scale formation; decarburization possible | Clean, bright finish; no oxidation or decarburization |

| Part Cleanliness | Requires post-treatment cleaning (e.g., sandblasting) | Parts are clean and ready for use |

| Process Control & Consistency | Good for general applications | Excellent for high-precision, repeatable results |

| Ideal For | Cost-effective processing of non-critical parts | High-performance alloys, tool steels, aerospace, and medical components |

Need Precise, Contamination-Free Heat Treatment?

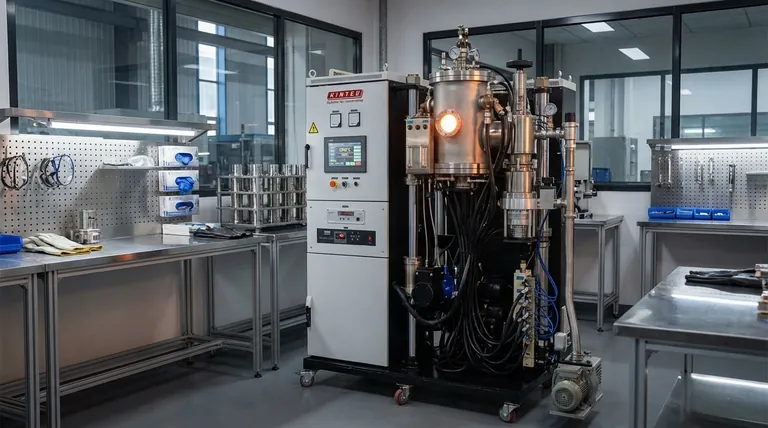

Your high-value components demand the ultimate in process control and surface integrity. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced vacuum furnace solutions that eliminate oxidation and decarburization, ensuring pristine finishes and superior material properties.

Our product line, including Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

→ Contact our experts today to discuss how our vacuum heat treatment solutions can enhance your product quality and performance.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What technological features enhance the efficiency of vacuum furnaces? Boost Performance with Advanced Control & Energy Savings

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures