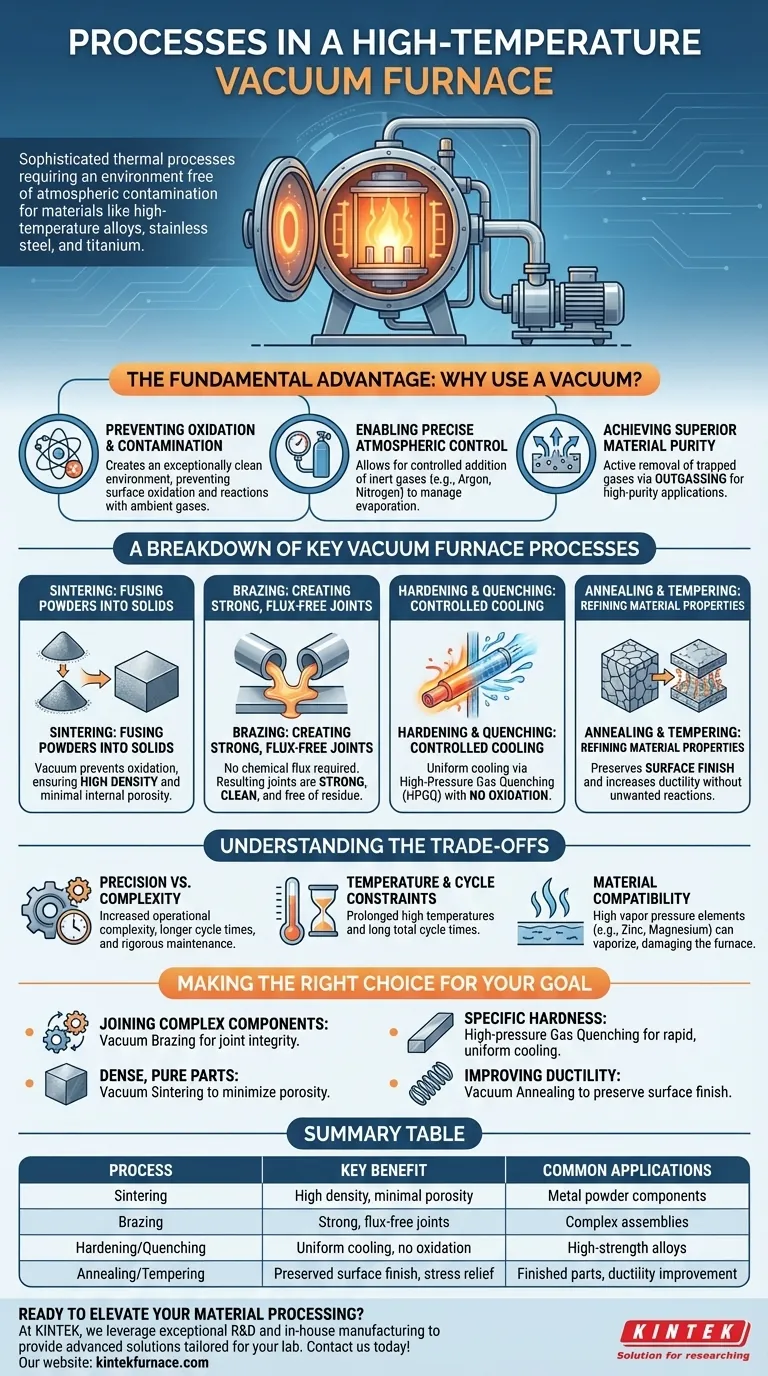

At its core, a high-temperature vacuum furnace is used for sophisticated thermal processes that require an environment free of atmospheric contamination. The most common applications include sintering, brazing, annealing, tempering, and hardening (quenching) for materials like high-temperature alloys, stainless steel, and titanium.

The fundamental purpose of using a vacuum is to create an ultra-clean, inert environment. By removing reactive gases like oxygen, the furnace prevents oxidation and contamination, enabling metallurgical results that are impossible to achieve in a standard atmospheric furnace.

The Fundamental Advantage: Why Use a Vacuum?

The decision to use a vacuum furnace is driven by the need for absolute control over the processing environment. This control prevents unwanted chemical reactions that degrade material quality.

Preventing Oxidation and Contamination

By pumping out nearly all atmospheric gases, a vacuum furnace creates an exceptionally clean environment. This prevents a material's surface from oxidizing or reacting with ambient gases at high temperatures.

This is critical for sensitive alloys where even minor surface oxidation can compromise the final component's structural integrity or performance.

Enabling Precise Atmospheric Control

A vacuum is not just about removing gases; it is also about creating a perfect baseline for adding them back in a controlled manner.

Operators can introduce a specific partial pressure of an inert gas like argon or nitrogen. This technique can be used to manage effects like the vaporization of certain elements, such as chromium in steel, ensuring the material's chemistry remains stable.

Achieving Superior Material Purity

The vacuum environment actively pulls trapped gases out of the material itself in a process called outgassing. This purifies the workload, which is essential for applications in aerospace, medical, and electronics where material purity is paramount.

A Breakdown of Key Vacuum Furnace Processes

Each process leverages the vacuum environment to achieve a specific, high-quality outcome.

Sintering: Fusing Powders into Solids

Vacuum sintering is the process of heating compacted metal powders to just below their melting point, causing the particles to fuse into a solid, dense object.

The vacuum prevents trapped gases and ensures there is no oxidation between powder granules, resulting in components with high density and minimal internal porosity.

Brazing: Creating Strong, Flux-Free Joints

Vacuum brazing joins multiple components using a filler metal that melts and flows into the joint.

Because the vacuum environment is inherently clean, this process requires no chemical flux, which is normally needed to remove oxides. The resulting joints are exceptionally strong, clean, and free of corrosive flux residue.

Hardening and Quenching: Controlled Cooling for Strength

Hardening involves heating a metal and then cooling it rapidly (quenching) to lock in a specific crystalline structure.

In a vacuum furnace, this is often done via high-pressure gas quenching (HPGQ). An inert gas is rapidly introduced into the chamber to cool the part uniformly, minimizing the risk of distortion or cracking while completely avoiding the oxidation that occurs with open-air or oil quenching.

Annealing and Tempering: Refining Material Properties

Annealing and tempering are heat treatments used to soften metals, increase their ductility, and relieve internal stresses created during manufacturing.

Performing these processes in a vacuum ensures the material's surface finish is preserved and that no unwanted reactions occur, which is especially important for finished or near-finished parts.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Precision vs. Complexity

The high level of control offered by a vacuum furnace comes with increased operational complexity. Achieving and maintaining a high vacuum requires specialized equipment, longer cycle times for pump-down, and more rigorous maintenance schedules compared to atmospheric furnaces.

Temperature and Cycle Constraints

Furnaces have a maximum rated temperature that should not be exceeded for prolonged periods to ensure equipment longevity. The entire cycle—including pumping down to the target vacuum level, heating, soaking, and cooling—is often significantly longer than a comparable atmospheric process.

Material Compatibility

Certain materials are not suitable for high-vacuum processing. Elements with a high vapor pressure, like zinc, cadmium, or magnesium, can vaporize at high temperatures under vacuum. This can damage the furnace and alter the chemical composition of the alloy being treated.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace process should be based on the required outcome for your material.

- If your primary focus is joining complex components: Vacuum brazing offers superior joint integrity without the risk of flux contamination.

- If your primary focus is creating dense, pure parts from metal powders: Vacuum sintering is the ideal method for minimizing porosity and eliminating internal contaminants.

- If your primary focus is achieving specific hardness in sensitive alloys: High-pressure gas quenching provides rapid, uniform cooling without oxidation.

- If your primary focus is improving the ductility or relieving stress in a finished part: Vacuum annealing preserves the surface finish and material purity.

Ultimately, a high-temperature vacuum furnace is a tool of precision, enabling material transformations that are simply not achievable in a standard atmosphere.

Summary Table:

| Process | Key Benefit | Common Applications |

|---|---|---|

| Sintering | High density, minimal porosity | Metal powder components |

| Brazing | Strong, flux-free joints | Complex assemblies |

| Hardening/Quenching | Uniform cooling, no oxidation | High-strength alloys |

| Annealing/Tempering | Preserved surface finish, stress relief | Finished parts, ductility improvement |

Ready to elevate your material processing with precision high-temperature vacuum furnaces?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored for your lab. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs.

Whether you're in aerospace, medical, or electronics, our furnaces ensure superior purity, oxidation prevention, and precise control for processes like sintering, brazing, and annealing.

Contact us today to discuss how we can help you achieve flawless results and enhance your laboratory's efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety