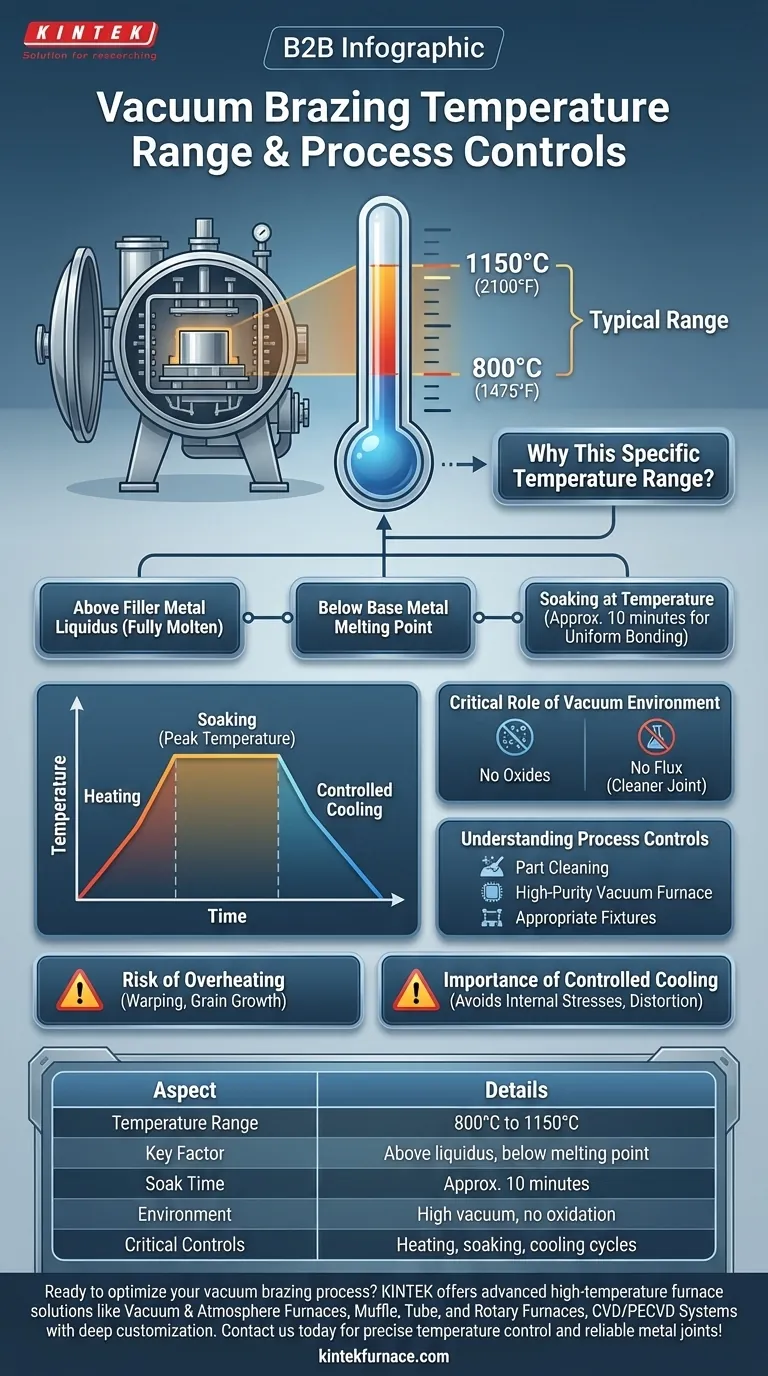

In vacuum brazing, the process is typically conducted within a temperature range of 800°C to 1150°C (approximately 1475°F to 2100°F). This temperature is carefully selected to be above the liquidus point of the brazing filler metal—the temperature at which it becomes fully liquid—but below the melting point of the components being joined. The assembly is held at this peak temperature, a step known as "soaking," for a short duration, often around 10 minutes, before undergoing a controlled cooling cycle.

The specific temperature is not a standalone number; it is the peak of a precisely controlled thermal cycle. The success of vacuum brazing depends on managing the entire profile—heating, soaking, and cooling—within a high-vacuum environment to achieve a pure, flux-free metallurgical bond.

Why This Specific Temperature Range?

The selection of a brazing temperature is a critical engineering decision dictated by the materials involved. It's a careful balance to ensure the filler metal flows correctly without damaging the parent materials.

The Role of the Filler Metal

The primary factor determining the brazing temperature is the filler metal alloy. Each alloy has a specific melting range, and the process temperature must be high enough for it to become fully liquid and flow freely into the joint.

The 'Liquidus' and 'Solidus' Temperatures

Brazing alloys don't melt at a single point. They melt over a range defined by the solidus (when melting begins) and liquidus (when it is fully molten). The brazing temperature must be set above the liquidus temperature to ensure the alloy has the low viscosity needed for capillary action.

Soaking at Temperature

Once the peak temperature is reached, it is held constant for a set period. This "soaking" ensures the entire assembly reaches a uniform temperature and provides sufficient time for the molten filler metal to penetrate the joint completely, creating a strong, continuous bond.

The Critical Role of the Vacuum Environment

Performing this process in a vacuum is what distinguishes vacuum brazing. The temperature is only effective because the atmosphere has been removed.

Preventing Oxidation

The high vacuum (the absence of oxygen and other reactive gases) prevents the formation of oxides on the surfaces of both the base metals and the filler metal. Oxides act as a barrier that would otherwise block the filler metal from wetting and bonding with the base materials.

Eliminating the Need for Flux

In conventional brazing, a chemical flux is used to remove oxides. Vacuum brazing achieves the same goal through a clean environment, resulting in a cleaner joint with no risk of flux entrapment, which can cause corrosion and weak points.

Understanding the Process Controls

Achieving the right temperature is only one part of a successful vacuum brazing operation. The entire process must be meticulously controlled.

It's More Than Just Temperature

Success relies on a chain of controlled variables. This includes the scrupulous cleaning of parts before assembly, the use of a high-purity vacuum furnace, and the design of appropriate fixtures to hold the parts in alignment during the thermal cycle.

The Risk of Overheating

Exceeding the required temperature can be detrimental. It can cause the base metals to warp, sag, or suffer from grain growth, which degrades their mechanical properties. In extreme cases, it can even lead to the unintended melting of the parent materials.

The Importance of Controlled Cooling

The cooling rate after the soak is just as critical as the heating. An uncontrolled or excessively fast cooling rate can introduce internal stresses, distortion, or create brittle metallurgical phases in the joint, compromising its integrity.

Making the Right Choice for Your Goal

To properly specify a vacuum brazing process, you must consider the relationship between the materials, the joint design, and the final application.

- If your primary focus is material selection: Ensure the filler metal's liquidus temperature is well below the melting point or heat treatment temperature of your base materials.

- If your primary focus is joint strength and reliability: Emphasize process controls, specifying strict cleanliness standards and a well-defined thermal cycle, including soak time and a controlled cooling rate.

- If your primary focus is design for manufacturing: Design the joint with clearances that are optimized for the chosen filler metal's flow characteristics at the specified brazing temperature.

Mastering vacuum brazing is about mastering the entire thermal process, not just hitting a target temperature.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | 800°C to 1150°C (approx. 1475°F to 2100°F) |

| Key Factor | Above filler metal liquidus, below base metal melting point |

| Soak Time | Typically around 10 minutes for uniform bonding |

| Environment | High vacuum to prevent oxidation and eliminate flux |

| Critical Controls | Heating, soaking, and controlled cooling cycles |

Ready to optimize your vacuum brazing process? At KINTEK, we specialize in delivering advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces, as well as CVD/PECVD Systems, all with deep customization capabilities to meet your specific experimental requirements. Whether you're in aerospace, automotive, or research, our expertise ensures strong, reliable metal joints with precise temperature control. Contact us today to discuss how we can enhance your laboratory's efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering