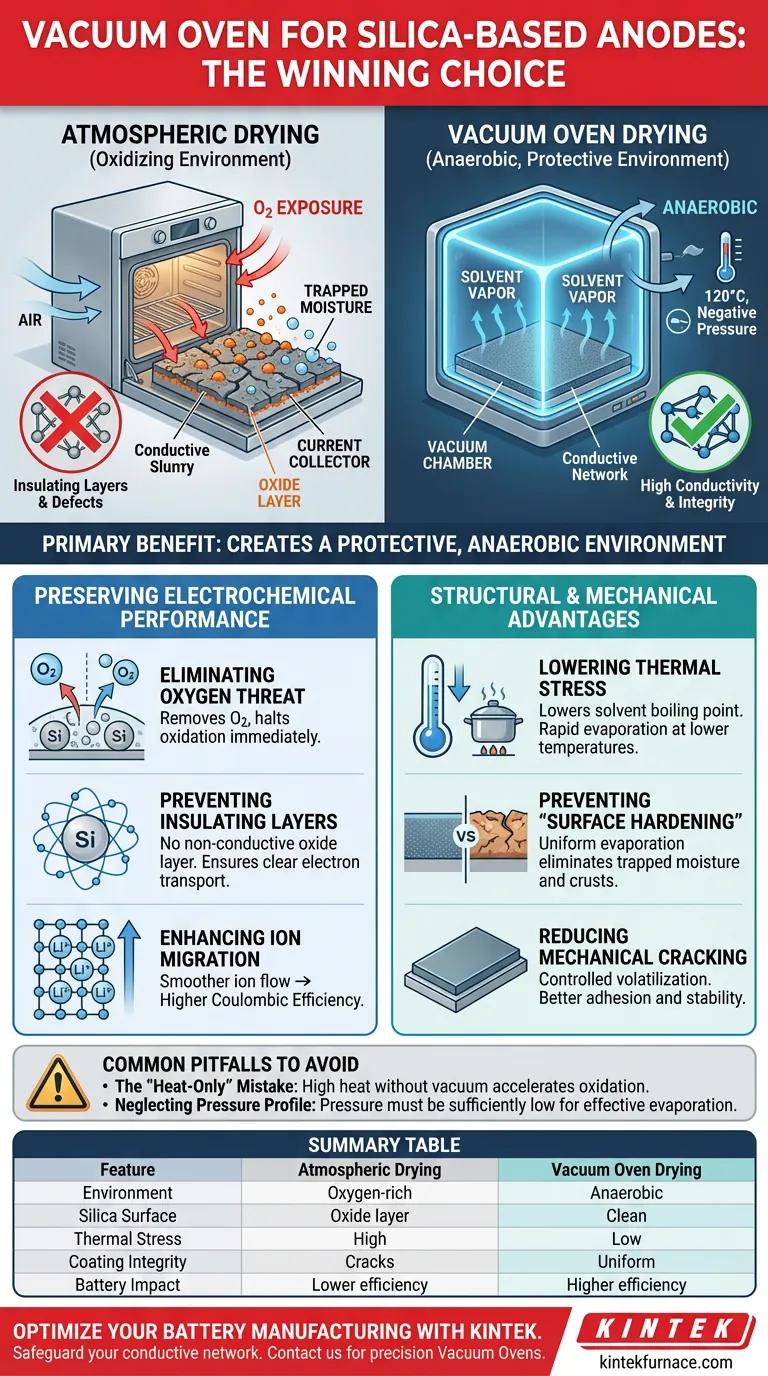

The primary benefit of using a Vacuum Oven for silica-based anode coatings is the creation of a protective, anaerobic environment.

By operating at negative pressure (typically at 120°C), the oven allows for solvent evaporation while strictly excluding oxygen. This prevents the surface oxidation of silica nanoparticles, ensuring the electrode maintains high conductivity and mechanical integrity compared to atmospheric drying.

Core Takeaway The vacuum environment is critical because it prevents the formation of non-conductive oxide layers on silica particles. By preserving the electrode’s conductive network, this process eliminates obstacles to ion migration and directly enhances the coulombic efficiency of the final lithium-ion battery.

Preserving Electrochemical Performance

The deep need in battery manufacturing is not just drying the material, but preserving its chemical properties during the process. Atmospheric drying exposes sensitive materials to reactive elements; vacuum drying neutralizes this threat.

Eliminating the Oxygen Threat

Silica-based anodes are highly susceptible to oxidation. Atmospheric drying inherently exposes the coating to oxygen, which reacts with the silica nanoparticles. Vacuum drying removes oxygen from the chamber, creating an anaerobic environment that halts these chemical reactions immediately.

Preventing Insulating Layers

When silica oxidizes, it forms a non-conductive oxide layer on the particle surface. This layer acts as an electrical insulator, disrupting the conductive network within the electrode. By preventing this layer, the vacuum oven ensures a clear path for electron transport.

Enhancing Ion Migration

The physical obstacles created by oxidation do not just block electrons; they impede lithium-ion movement. A clean, oxide-free silica surface facilitates smoother ion migration. This leads to higher coulombic efficiency, a critical metric for battery cycle life and capacity.

Structural and Mechanical Advantages

Beyond chemical preservation, the physics of vacuum drying offers superior structural control over the electrode coating compared to atmospheric methods.

Lowering Thermal Stress

Vacuum pressure significantly lowers the boiling point of solvents. This allows solvents to evaporate rapidly at lower temperatures, reducing the thermal stress on the coating. This prevents the thermal degradation or agglomeration of nanoparticles often caused by the high heat required in atmospheric drying.

Preventing "Surface Hardening"

Atmospheric drying often causes the surface of the slurry to dry faster than the interior, forming a hard "crust." This crust traps moisture inside the electrode, leading to defects. Vacuum drying promotes uniform evaporation, eliminating trapped moisture and ensuring the binder is evenly distributed.

Reducing Mechanical Cracking

Rapid, uneven drying in atmospheric conditions frequently leads to surface cracking. The controlled volatilization in a vacuum oven maintains the coating's integrity. This results in better adhesion between the active material and the current collector, improving the electrode's overall mechanical stability.

Common Pitfalls to Avoid

While vacuum drying is superior for this application, misunderstanding the process can lead to suboptimal results.

The "Heat-Only" Mistake

A common error is assuming high heat can substitute for vacuum pressure. Raising the temperature without a vacuum will accelerate oxidation and likely degrade the binder. You must rely on negative pressure, not just heat, to drive solvent evaporation efficiently.

Neglecting the Pressure Profile

Simply turning on the vacuum is not enough; the pressure must be low enough to drop the solvent's boiling point effectively. If the pressure is not sufficiently reduced, you lose the benefit of low-temperature evaporation. This can lead to prolonged drying times and residual moisture deep within porous structures.

Making the Right Choice for Your Goal

To maximize the performance of your silica-based anodes, tailor your drying strategy to your specific engineering targets.

- If your primary focus is Coulombic Efficiency: Prioritize the anaerobic capability of the oven to strictly prevent non-conductive oxide layer formation on the silica.

- If your primary focus is Mechanical Stability: Leverage the low-temperature boiling point effect to prevent cracking and ensure uniform binder distribution on the current collector.

Ultimately, the Vacuum Oven is not merely a drying tool; it is a chemical preservation system that safeguards the conductive network of your battery.

Summary Table:

| Feature | Atmospheric Drying | Vacuum Oven Drying |

|---|---|---|

| Environment | Oxygen-rich (Oxidizing) | Anaerobic (Protective) |

| Silica Surface | Forms non-conductive oxide layer | Remains clean and conductive |

| Thermal Stress | High (requires high boiling points) | Low (negative pressure lowers boiling point) |

| Coating Integrity | Prone to surface crusting and cracks | Uniform evaporation; crack-free |

| Battery Impact | Lower ion migration efficiency | Higher coulombic efficiency & cycle life |

Optimize Your Battery Manufacturing with KINTEK

Don't let oxidation compromise your electrode performance. KINTEK’s precision Vacuum Ovens are engineered to provide the perfect anaerobic environment, ensuring your silica-based anodes maintain maximum conductivity and mechanical integrity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your lab's unique high-temperature and drying needs.

Ready to upgrade your material processing? Contact us today to find your custom solution!

Visual Guide

References

- Sohan Thombare, C.D. Lokhande. Synthesis and characterization of crystalline cristobalite alpha low silicon dioxide nanoparticles: a cost-effective anode for lithium-ion battery. DOI: 10.1007/s10854-024-13153-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a vacuum drying oven provide superior results for Cs3Cu2I5:Tb precipitates? Preserve Your Scintillation Quality

- What are the technical requirements for a high-performance silicon nitride sintering furnace?

- What are some additional applications of continuous vacuum furnaces? Unlock Advanced Material Processing

- What is the role of the Discrete Ordinates (DO) model in vacuum furnace simulation? Master Radiative Heat Transfer

- How does a laboratory vacuum drying oven address porous bone scaffold requirements? Ensuring Bio-Material Integrity

- How does the vacuum pumping system in a vertical vacuum furnace operate? Learn the Multi-Stage Process for Precision

- How does a precision dynamic vacuum annealing furnace facilitate phase transformation? Boost BaSnF4 Electrolyte Performance

- How do computer-controlled systems enhance vacuum furnace operations? Achieve Precision and Repeatability in Heat Treatment