In modern high-performance manufacturing, computer-controlled systems are the critical element that transforms a vacuum furnace from a simple heating chamber into a precise metallurgical tool. These systems automate the entire heat treatment cycle, from pump-down to final quench, ensuring that every part is processed under the exact same conditions every time. This guarantees exceptional repeatability, optimizes material properties, and provides a level of process control that is impossible to achieve manually.

The fundamental enhancement is not merely automation for convenience; it is the shift to data-driven process control. Computer systems enable you to define, execute, and verify the perfect treatment cycle, eliminating the variability that leads to inconsistent quality and material failure.

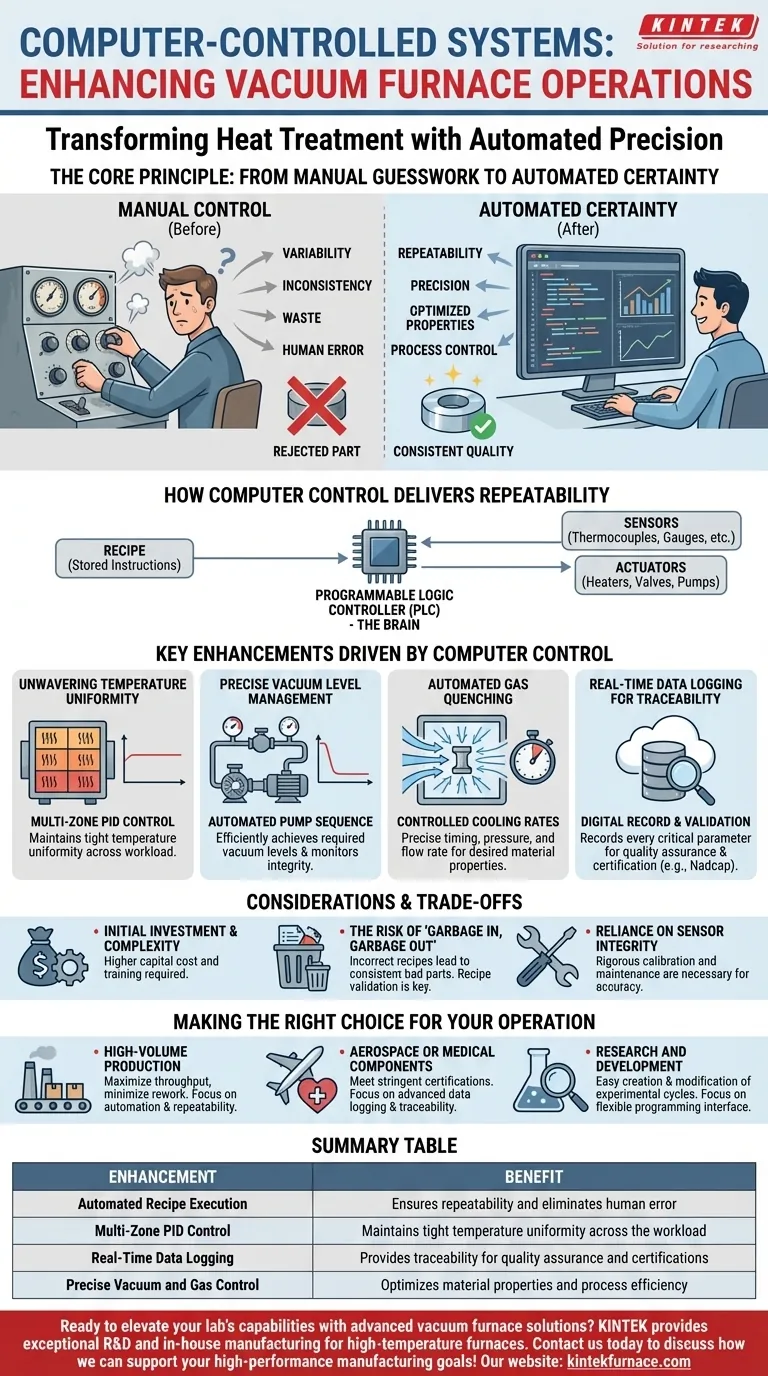

The Core Principle: From Manual Guesswork to Automated Certainty

Before computerization, furnace operation relied heavily on operator skill, analog gauges, and manual adjustments. This approach was prone to human error and inherent inconsistencies between batches.

The Problem with Manual Control

Manual operation introduces variability at every step. Slight differences in an operator's timing for gas injection, temperature ramps, or vacuum levels can lead to significant deviations in the final product's metallurgical structure and mechanical properties.

This lack of precision often results in a higher rate of rejected parts, wasted energy, and difficulty in meeting the stringent certification requirements of industries like aerospace or medical devices.

How Computer Control Delivers Repeatability

Computer systems operate based on pre-programmed recipes. A recipe is a stored set of instructions that defines every parameter of the furnace cycle: heating rates, temperature setpoints, soak times, vacuum levels, and gas quench pressures.

Once a recipe is validated, the computer can execute it identically for hundreds of cycles. This ensures that the first part produced in a batch and the last part produced weeks later have undergone the exact same thermal process.

The Role of the Programmable Logic Controller (PLC)

The "brain" of the modern furnace is the Programmable Logic Controller (PLC) or a similar industrial computer. It reads data from sensors (thermocouples, pressure gauges) in real-time and makes instantaneous adjustments to actuators (heating elements, valves, pumps) to perfectly match the pre-programmed recipe.

Key Enhancements Driven by Computer Control

Computer control isn't a single feature; it's an integrated system that improves every aspect of the furnace's operation, leading to superior outcomes.

Unwavering Temperature Uniformity

Advanced systems use multi-zone PID (Proportional-Integral-Derivative) control. The furnace's heating chamber is divided into several zones, each with its own thermocouple and independent power control. The computer constantly adjusts power to each zone to maintain exceptionally tight temperature uniformity across the entire workload, preventing hot or cold spots.

Precise Vacuum Level Management

Computer control automates the complex sequence of operating roughing pumps, diffusion pumps, and holding pumps to achieve the required vacuum level efficiently. It also monitors for leaks in real-time, alerting operators or initiating a safe shutdown if the vacuum integrity is compromised.

Automated Gas Quenching

The cooling phase is just as critical as the heating phase. The computer controls the precise timing, pressure, and flow rate of the quenching gas (like nitrogen or argon) to achieve the specific cooling rate required to lock in desired material properties such as hardness and strength.

Real-Time Data Logging for Traceability

Every critical parameter—temperature, pressure, time, gas flow—is recorded throughout the cycle. This creates a detailed digital record for each batch, which is essential for quality assurance, process validation, and industry certifications (e.g., Nadcap for aerospace).

Understanding the Trade-offs and Considerations

While the benefits are significant, adopting computer-controlled systems requires a clear understanding of the associated responsibilities.

Initial Investment and Complexity

These systems represent a higher upfront capital cost compared to simpler, manual furnaces. They also require operators who are trained not just in furnace operation, but in interacting with the control interface and understanding the programming logic.

The Risk of "Garbage In, Garbage Out"

The system's precision is a double-edged sword. An incorrectly programmed recipe will be executed with perfect, unwavering fidelity, consistently producing bad parts. The development and validation of correct recipes are paramount.

Reliance on Sensor Integrity

The entire system depends on accurate data from its sensors. A faulty thermocouple or a miscalibrated pressure gauge can cause the controller to make incorrect decisions. A rigorous sensor calibration and maintenance program is not optional; it is a necessity.

Making the Right Choice for Your Operation

The decision to invest in or upgrade to a specific computer-controlled system should align directly with your operational goals.

- If your primary focus is high-volume production: The key benefit is the system's automation and repeatability, which maximize throughput and minimize costly rework.

- If your primary focus is aerospace or medical components: The most critical feature is the advanced data logging and traceability for meeting stringent certification and quality assurance requirements.

- If your primary focus is research and development: You need a system with a flexible and intuitive programming interface that allows for easy creation and modification of experimental heat treatment cycles.

By leveraging computer control, you are fundamentally investing in the certainty and quality of your final product.

Summary Table:

| Enhancement | Benefit |

|---|---|

| Automated Recipe Execution | Ensures repeatability and eliminates human error |

| Multi-Zone PID Control | Maintains tight temperature uniformity across the workload |

| Real-Time Data Logging | Provides traceability for quality assurance and certifications |

| Precise Vacuum and Gas Control | Optimizes material properties and process efficiency |

Ready to elevate your lab's capabilities with advanced vacuum furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering enhanced repeatability, efficiency, and quality. Contact us today to discuss how we can support your high-performance manufacturing goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today