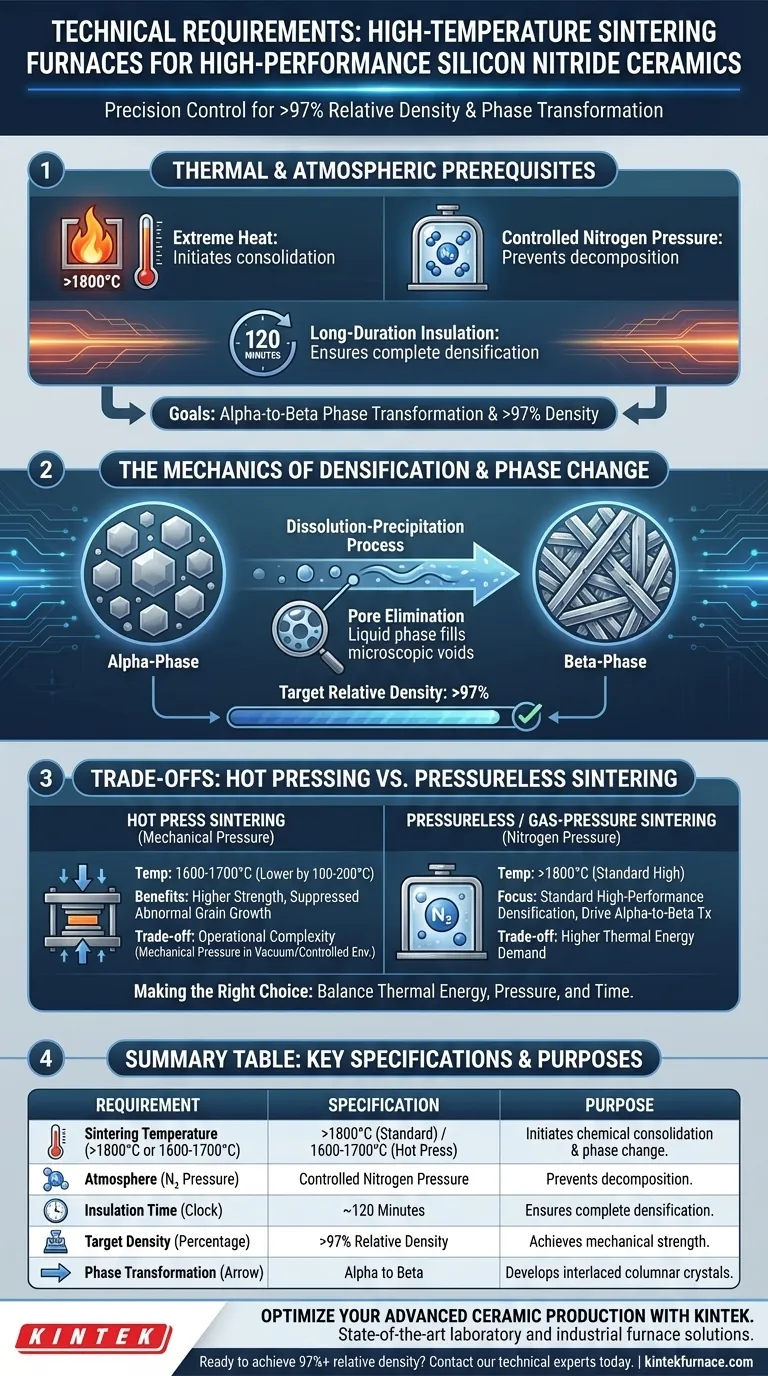

To produce high-performance silicon nitride ceramics, a sintering furnace must be capable of sustaining temperatures exceeding 1800°C under a controlled nitrogen pressure atmosphere. Furthermore, the system requires the capacity for long-duration insulation—typically around 120 minutes—to ensure complete densification and phase transformation.

High-performance ceramics require more than just heat; they require a precisely controlled environment to manage phase changes. The furnace must facilitate a dissolution-precipitation process that transforms alpha-phases to beta-phases, achieving relative densities exceeding 97% through extended pore-filling time.

Thermal and Atmospheric Prerequisites

Reaching the Thermal Threshold

The furnace must reliably achieve and hold temperatures exceeding 1800°C. This extreme heat is the fundamental catalyst required to initiate the specific chemical interactions necessary for silicon nitride consolidation.

The Role of Nitrogen Pressure

Operating under nitrogen pressure is mandatory at these temperatures. Without this pressurized atmosphere, silicon nitride is prone to decomposition rather than densification, compromising the structural integrity of the final product.

Managing Phase Transformation

The thermal environment must support the dissolution-precipitation process. This mechanism is responsible for transforming the material from alpha-silicon nitride phases into the desired beta-silicon nitride phases.

The Mechanics of Densification

Creating the Crystal Structure

The primary goal of the sintering cycle is to develop an interlaced columnar crystal structure. This specific microstructure is what grants high-performance silicon nitride its renowned mechanical properties.

The Importance of Insulation Time

High temperature alone is insufficient; the furnace must maintain these conditions for extended periods, such as 120 minutes.

Achieving Pore Elimination

During this long insulation period, the liquid phase formed by sintering aids flows to fill microscopic voids. This process is critical for achieving a final material with a relative density exceeding 97%.

Understanding the Trade-offs: Hot Pressing vs. Pressureless

Reducing Thermal Demands

If the furnace utilizes hot press sintering (applying mechanical pressure), the required process temperature can be lowered by 100-200°C compared to pressureless or gas-pressure systems.

Enhancing Mechanical Properties

Mechanical pressure provides an external driving force that facilitates particle rearrangement and plastic deformation. This method effectively suppresses abnormal grain growth, often resulting in higher strength and thermal conductivity.

Operational Complexity

While hot pressing reduces temperature requirements, it introduces the complexity of maintaining continuous mechanical pressure (e.g., 10 MPa) in a vacuum or controlled environment. This is often a trade-off between thermal energy consumption and mechanical equipment complexity.

Making the Right Choice for Your Goal

Selecting the correct furnace configuration depends heavily on your specific microstructural and density targets.

- If your primary focus is standard high-performance densification: Prioritize a furnace capable of >1800°C temperatures with high nitrogen pressure capabilities to drive the alpha-to-beta transformation without mechanical aid.

- If your primary focus is maximizing strength at lower temperatures: Select a hot press sintering furnace to leverage mechanical pressure for full densification and grain growth suppression at significantly reduced thermal loads.

True high-performance ceramic production is the result of precisely balancing thermal energy, atmospheric pressure, and time to eliminate porosity at the microscopic level.

Summary Table:

| Requirement | Specification | Purpose |

|---|---|---|

| Sintering Temperature | >1800°C (Standard) / 1600-1700°C (Hot Press) | Initiates chemical consolidation and alpha-to-beta phase change. |

| Atmosphere | Controlled Nitrogen Pressure | Prevents decomposition of silicon nitride at extreme temperatures. |

| Insulation Time | ~120 Minutes | Ensures complete densification and pore elimination. |

| Target Density | >97% Relative Density | Achieves necessary mechanical strength and structural integrity. |

| Phase Transformation | Alpha-phase to Beta-phase | Develops interlaced columnar crystals for superior performance. |

Optimize Your Advanced Ceramic Production with KINTEK

Producing high-performance silicon nitride requires extreme precision in temperature control and atmospheric stability. KINTEK provides state-of-the-art laboratory and industrial furnace solutions designed to meet these rigorous demands.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature sintering furnaces. Whether you require high-pressure nitrogen environments for gas-pressure sintering or mechanical precision for hot pressing, our systems are fully customizable to your unique material research or production needs.

Ready to achieve 97%+ relative density in your ceramics? Contact our technical experts today to discuss how our high-temperature solutions can enhance your laboratory's efficiency and product quality.

Visual Guide

References

- Yun-Zhuo Zhang, Yousheng Zou. Pyrolysis Kinetics-Driven Resin Optimization for Enhanced Reliability in Ceramic Vat Photopolymerization Manufacturing. DOI: 10.3390/ma18174004

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are inert gases necessary in vacuum furnaces? Unlock Precision in Heat Treatment

- Why Multiple Vacuum & Argon Cycles for High-Entropy Alloys? Achieve Peak Purity & Chemical Precision!

- How does an industrial vacuum sintering furnace contribute to the densification of NdFeB magnets? | Expert Insights

- Why is a vacuum oven used for drying ionogels? Preserve Structural Integrity for Precise Electron Microscopy

- How does the two-stage heat treatment in a vacuum sintering furnace optimize HA/Ti scaffolds? Master the Fabrication Process

- How does the vacuum environment affect gas porosity in castings? Eliminate Defects for Stronger Parts

- What innovations are being made in graphite for vacuum furnaces? Boost Efficiency with Advanced Coatings & Custom Parts

- What is the role of a high-precision vacuum drying oven in biochar activation? Unlock Superior Surface Area