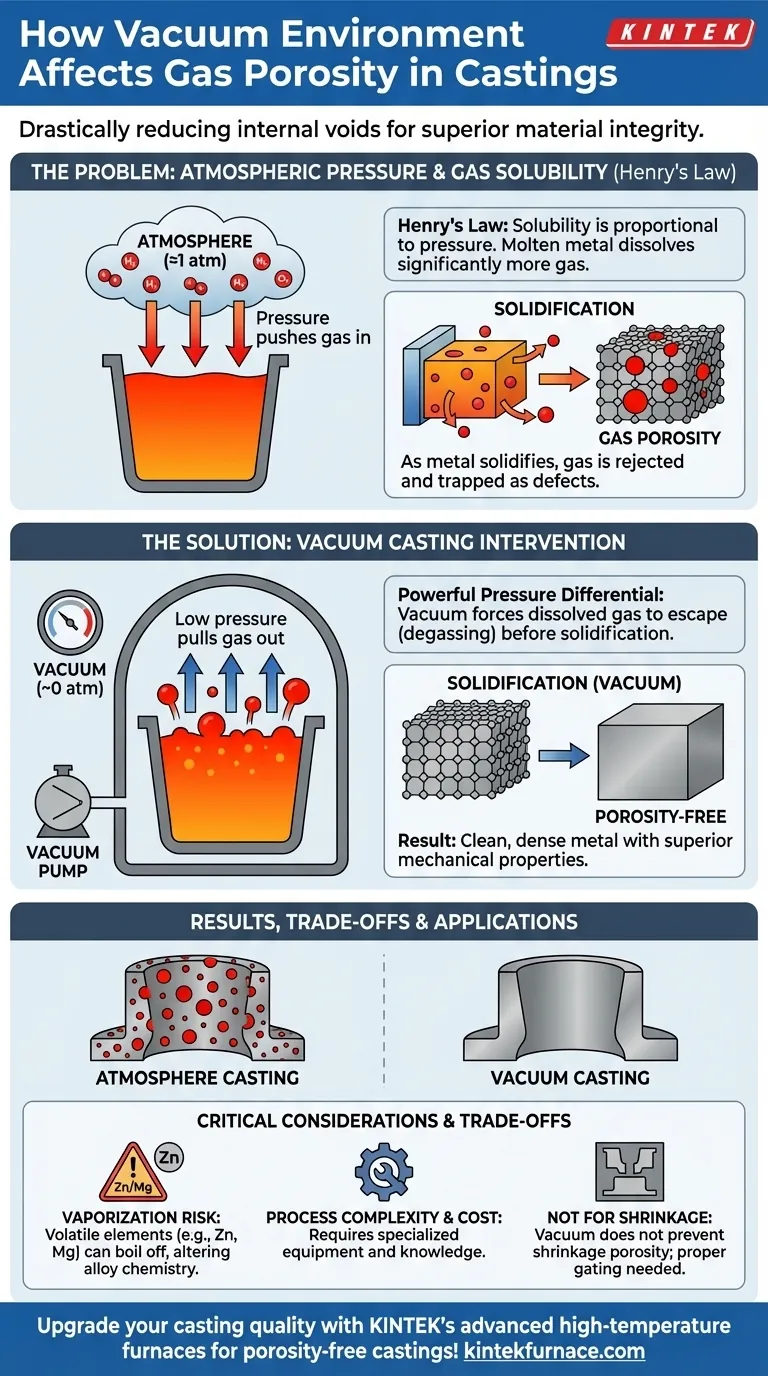

A vacuum environment fundamentally alters the physics of casting to drastically reduce or eliminate gas porosity. By removing atmospheric pressure, a vacuum creates a powerful differential that pulls dissolved gases, primarily hydrogen, out of the molten metal before it has a chance to solidify and trap them as internal voids or bubbles.

The core problem is that molten metal can dissolve far more gas than solid metal. A vacuum directly counteracts this by lowering the pressure above the melt, forcing trapped gases to escape before they can form strength-reducing porosity during solidification.

The Physics of Gas in Molten Metal

To understand why a vacuum is so effective, we must first understand how gas gets into the metal in the first place. The entire process is governed by fundamental laws of chemistry and physics.

Henry's Law: The Governing Principle

The solubility of a gas in a liquid is directly proportional to the partial pressure of that gas above the liquid. This is known as Henry's Law.

In a standard atmosphere, the pressure exerted by the air (approximately 14.7 psi or 1 bar) actively pushes gases like hydrogen, nitrogen, and oxygen into the molten metal.

The Problem of State Change

When metal is in its liquid state, its atomic structure is loose and can accommodate a significant volume of dissolved gas atoms, particularly hydrogen.

As the metal cools and solidifies, its structure becomes a dense, ordered crystal lattice. This solid lattice has drastically lower solubility for gas.

How Porosity Forms

During solidification, the gas that was comfortably dissolved in the liquid metal is suddenly rejected. With nowhere to go, this excess gas coalesces into bubbles.

These bubbles become trapped within the solidifying metal, creating the internal voids known as gas porosity. These defects act as stress concentrators and can severely compromise the mechanical integrity of the final casting.

How Vacuum Casting Intervenes

Vacuum casting is a direct and forceful intervention in this process. It tackles the root cause by manipulating the pressure variable in Henry's Law.

Creating a Powerful Pressure Differential

By placing the molten metal in a chamber and pumping out the air, the pressure above the melt is reduced from atmospheric pressure to a near-perfect vacuum.

This removes the force that was pushing gas into the metal. More importantly, it creates a state where the internal pressure of the dissolved gas within the metal is far higher than the external pressure of the vacuum.

Forcing Degassing to Occur

This massive pressure imbalance forces the dissolved gases to rapidly bubble out of the solution, a process often visible as a "boil" on the surface of the melt.

The metal is effectively degassed before the pouring and solidification process even begins, removing the gas that would have later formed porosity.

Preventing Gas Reabsorption

A crucial secondary benefit is that the vacuum environment prevents the now-clean molten metal from picking up more gas from the atmosphere during the pour or while it fills the mold.

Understanding the Trade-offs

While incredibly effective, vacuum casting is not a universal solution. It introduces its own set of technical challenges and considerations.

Vaporization of Alloying Elements

The most significant trade-off involves alloy composition. Under a hard vacuum, certain alloying elements with high vapor pressures (low boiling points) can "boil off" from the melt.

Elements like zinc, magnesium, and manganese are particularly susceptible. This can alter the final chemistry and mechanical properties of the alloy if not carefully controlled.

Process Complexity and Cost

Vacuum casting equipment is expensive to purchase, operate, and maintain. It requires specialized knowledge and adds significant complexity and cycle time to the manufacturing process.

Distinguishing Porosity Types

Vacuum is exceptionally effective against gas porosity. However, it does little to prevent shrinkage porosity, which is caused by the natural volume reduction of metal as it cools from liquid to solid. A proper gating and riser design is still required to address shrinkage.

Making the Right Choice for Your Application

Selecting the right casting process requires balancing quality requirements with cost and complexity.

- If your primary focus is maximum material integrity for critical parts: Vacuum casting is the superior choice for applications in aerospace, medical, or high-performance industries where porosity is unacceptable.

- If you are casting alloys with volatile elements: You must use precise partial pressure controls or alternative degassing methods (like inert gas sparging) to prevent losing valuable elements.

- If your goal is reducing general porosity in non-critical components: Optimizing melt practices to minimize hydrogen pickup and using simpler degassing techniques may be a more cost-effective first step.

By understanding the physics of gas solubility, you can strategically use a vacuum not just as a process, but as a precise tool to achieve the exact material properties your application demands.

Summary Table:

| Aspect | Effect in Vacuum Casting |

|---|---|

| Gas Solubility | Decreases due to lower pressure, forcing gases out of molten metal |

| Porosity Formation | Drastically reduced or eliminated, preventing internal voids |

| Alloy Integrity | Risk of vaporization for volatile elements like zinc and magnesium |

| Process Suitability | Ideal for critical parts in aerospace and medical industries |

Upgrade your casting quality with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, helping you achieve porosity-free castings for superior performance. Contact us today to discuss how we can enhance your process!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries