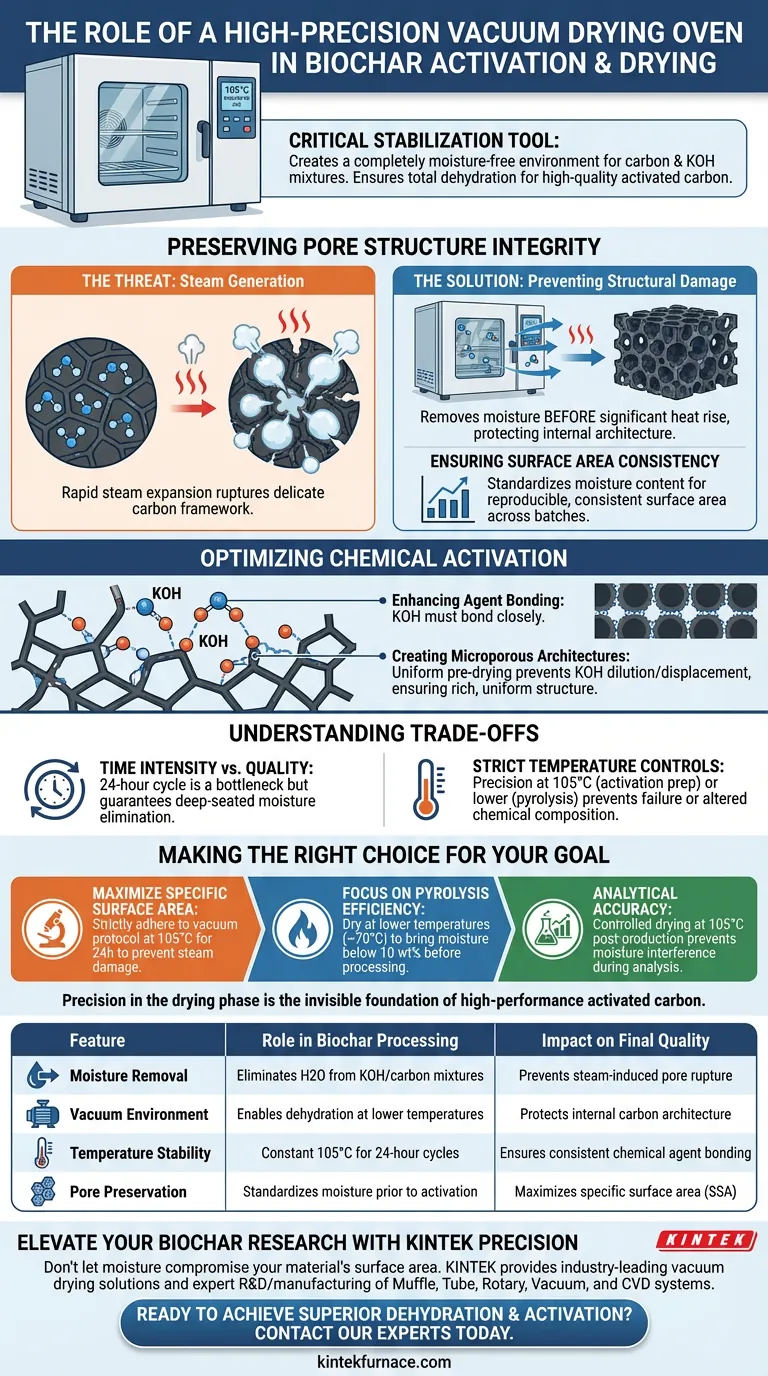

A high-precision vacuum drying oven serves as a critical stabilization tool in the biochar production process, specifically designed to create a completely moisture-free environment for carbon and potassium hydroxide (KOH) mixtures. By maintaining a vacuum state at 105°C for 24 hours, the oven ensures total dehydration, which is the prerequisite for achieving high-quality activated carbon.

The oven’s primary function is to eliminate moisture to prevent uncontrolled steam formation during high-temperature activation. This step is non-negotiable for protecting the biochar's pore structure and ensuring the consistency of its specific surface area.

Preserving Pore Structure Integrity

The Threat of Steam Generation

When biochar mixtures enter high-temperature activation, any residual moisture will instantly convert to steam. This rapid expansion can rupture the delicate carbon framework.

Preventing Structural Damage

The vacuum drying oven removes this risk by extracting moisture before the heat rises significantly. This protects the internal architecture of the material, preventing the collapse or distortion of pores.

Ensuring Surface Area Consistency

For activated carbon, the specific surface area is a key performance metric. By standardizing the moisture content prior to activation, the oven ensures that the resulting surface area measurements are reproducible and consistent across different batches.

Optimizing the Chemical Activation Process

Enhancing Agent bonding

During chemical activation, the activating agent (specifically KOH) must bond closely with the biochar framework.

Creating Microporous Architectures

Uniform pre-drying ensures that the KOH is not diluted or displaced by water pockets. This tight interaction is essential for generating a rich, uniform microporous structure during the subsequent firing phase.

Understanding the Trade-offs

Time Intensity vs. Quality

Using a high-precision vacuum oven is a time-intensive process, typically requiring a full 24-hour cycle. While this creates a bottleneck compared to rapid drying methods, it is the only way to guarantee the elimination of deep-seated moisture without triggering premature chemical reactions.

Strict Temperature Controls

Precision is required; temperatures must be maintained specifically (e.g., 105°C for activation prep or lower for pre-pyrolysis). Deviating from these set points can either fail to remove sufficient moisture or inadvertently alter the chemical composition of the biomass before the main processing begins.

Making the Right Choice for Your Goal

To maximize the effectiveness of your biochar processing, align your drying strategy with your specific objective:

- If your primary focus is maximizing specific surface area: Adhere strictly to the vacuum protocol at 105°C for 24 hours to prevent steam-induced pore damage.

- If your primary focus is pyrolysis efficiency: Ensure biomass is dried at lower temperatures (around 70°C) to bring moisture content below 10 wt% prior to processing.

- If your primary focus is analytical accuracy: Utilize controlled drying at 105°C post-production to prevent moisture interference during component analysis and adsorption experiments.

Precision in the drying phase is the invisible foundation of high-performance activated carbon.

Summary Table:

| Feature | Role in Biochar Processing | Impact on Final Quality |

|---|---|---|

| Moisture Removal | Eliminates H2O from KOH/carbon mixtures | Prevents steam-induced pore rupture |

| Vacuum Environment | Enables dehydration at lower temperatures | Protects internal carbon architecture |

| Temperature Stability | Constant 105°C for 24-hour cycles | Ensures consistent chemical agent bonding |

| Pore Preservation | Standardizes moisture prior to activation | Maximizes specific surface area (SSA) |

Elevate Your Biochar Research with KINTEK Precision

Don't let moisture compromise your material's surface area. KINTEK provides industry-leading vacuum drying solutions alongside our expert R&D and manufacturing of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are developing microporous architectures or scaling pyrolysis, our customizable lab high-temp furnaces ensure the precision your research demands.

Ready to achieve superior dehydration and activation results?

Contact Our Experts Today to find the perfect thermal solution for your lab's unique needs.

Visual Guide

References

- Zitong Zhuang, Hui Jin. Preparation of biochar adsorption material from walnut shell by supercritical CO2 pretreatment. DOI: 10.1007/s42773-024-00302-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the function of a high-vacuum furnace in tantalum carburization? Purity & Reaction Precision

- How does argon help control aluminum volatilization in vacuum furnaces? Master Your Smelting Yields

- How do vacuum furnaces work? Unlock Clean, High-Purity Heat Treatment

- What is the necessity of using a vacuum drying oven for the 70 °C treatment of synthesized TF-COF? Essential Guide

- What are the primary differences in sintering strategies for ceramic membranes? Optimize Your Thermal Processing

- What are the two main designs of vacuum furnaces? Compare Hot Wall vs Cold Wall for Your Lab

- How is furnace brazing applied in research and development? A Precision Tool for Material Science & Prototyping

- What are the key differences in pumping systems between low vacuum and high vacuum furnaces? Choose the Right System for Your Process