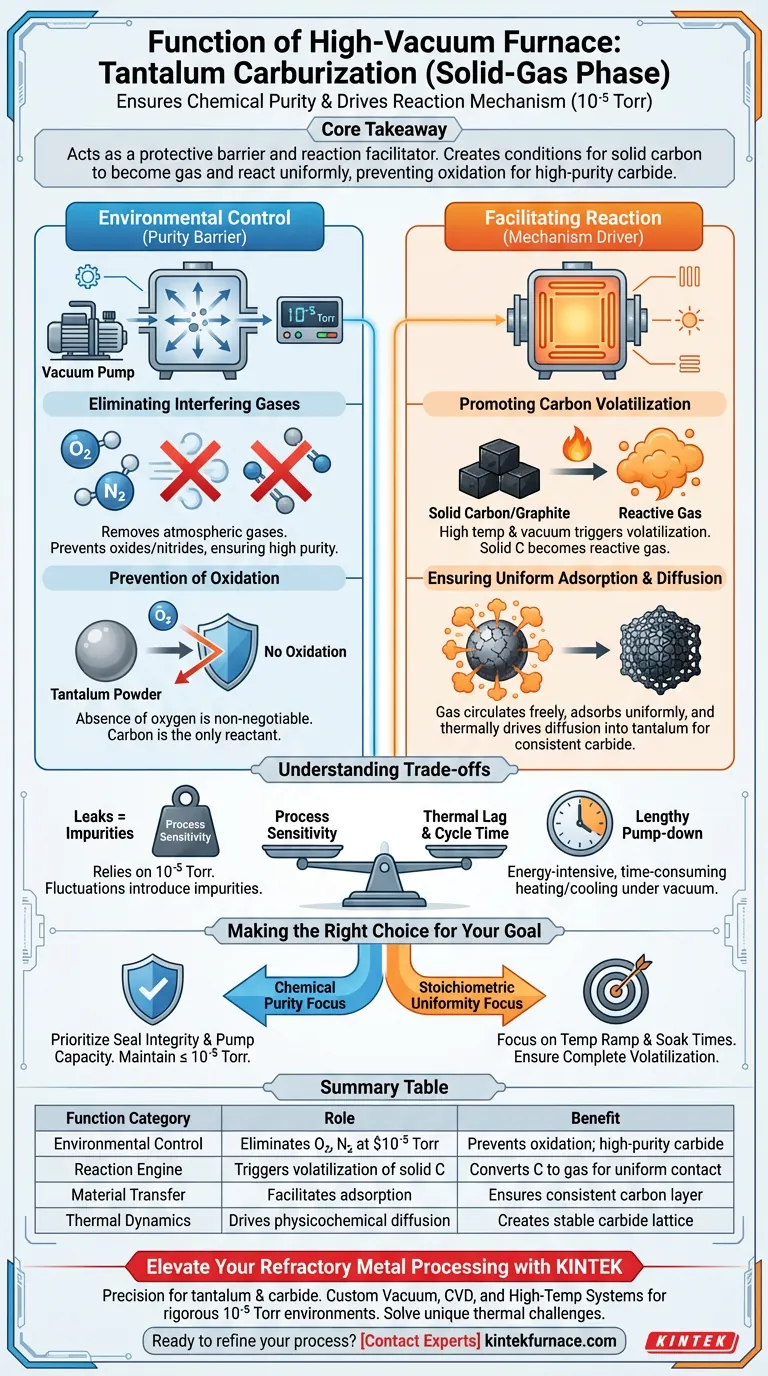

In the solid-gas phase carburization of tantalum powder, the high-vacuum furnace serves two distinct but interrelated functions: it ensures chemical purity and drives the reaction mechanism. Specifically, it establishes an ultra-low pressure environment (typically $10^{-5}$ Torr) to eliminate contaminants while simultaneously promoting the volatilization of carbon sources to allow for uniform diffusion into the tantalum substrate.

Core Takeaway The high-vacuum furnace acts as both a protective barrier and a reaction facilitator. It creates the necessary conditions for solid carbon to transform into a gas and react uniformly with tantalum powder, preventing oxidation and ensuring a high-purity carbide structure.

The Role of Environmental Control

Eliminating Interfering Gases

The primary role of the furnace is to create an "exclusion zone" for impurities. Tantalum is a refractory metal that is highly sensitive to interstitial impurities like oxygen and nitrogen.

By achieving a high vacuum around $10^{-5}$ Torr, the furnace removes atmospheric gases that would otherwise react with the tantalum. This ensures that the final tantalum carbide retains high purity, free from oxides or nitrides that would degrade its performance.

Prevention of Oxidation

Similar to processes used for Titanium or Ruthenium powders, the absence of oxygen is non-negotiable.

If oxygen were present during the high-temperature phase, the tantalum powder would oxidize rather than carburize. The vacuum environment guarantees that carbon is the only element reacting with the metal.

Facilitating the Reaction Mechanism

Promoting Carbon Volatilization

In solid-gas phase carburization, the carbon source is initially a solid, such as activated carbon or graphite.

The high-temperature vacuum environment triggers the volatilization of these carbon-containing agents. This phase change—converting solid carbon into a reactive gas—is the engine of the entire process.

Ensuring Uniform Adsorption

Once the carbon source volatilizes, the gas circulates freely around the tantalum powder particles.

The vacuum environment allows these gases to physically and chemically adsorb onto the surface of the tantalum powder without physical barriers. This ensures that every particle is exposed to the reactant equally.

Driving Physicochemical Diffusion

After adsorption, the carbon atoms must penetrate the tantalum metal to form the carbide lattice.

The thermal energy provided by the furnace drives this diffusion process. Because the environment is controlled, the diffusion occurs uniformly across the powder's surface, resulting in a consistent carbide layer and predictable material properties.

Understanding the Trade-offs

Process Sensitivity

While a high-vacuum furnace provides superior purity, it introduces significant process sensitivity.

The system relies on maintaining the $10^{-5}$ Torr threshold. Any fluctuation in pressure or minor leaks in the vacuum seal will immediately introduce impurities, likely ruining the batch by causing partial oxidation.

Thermal Lag and Cycle Time

Achieving and maintaining high vacuum at high temperatures is energy-intensive and time-consuming.

Unlike atmospheric furnaces, vacuum furnaces require lengthy pump-down cycles before heating can begin, and cooling must often occur under vacuum to prevent post-process oxidation. This reduces throughput compared to continuous atmosphere processes.

Making the Right Choice for Your Goal

To optimize the carburization of tantalum powder, focus on these operational parameters:

- If your primary focus is Chemical Purity: Prioritize the integrity of the vacuum seals and pump capacity to strictly maintain pressures at or below $10^{-5}$ Torr to exclude all interfering gases.

- If your primary focus is Stoichiometric Uniformity: Focus on the temperature ramp rates and soak times to ensure complete volatilization of the graphite/carbon agents for even diffusion.

The high-vacuum furnace is not merely a heating vessel; it is a precision tool that orchestrates the phase change of carbon to engineer the surface chemistry of tantalum.

Summary Table:

| Function Category | Role in Tantalum Carburization | Benefit to Process |

|---|---|---|

| Environmental Control | Eliminates oxygen and nitrogen at $10^{-5}$ Torr | Prevents oxidation; ensures high-purity carbide |

| Reaction Engine | Triggers volatilization of solid carbon sources | Converts carbon to gas for uniform surface contact |

| Material Transfer | Facilitates physical and chemical adsorption | Ensures consistent carbon layer across all powder particles |

| Thermal Dynamics | Drives physicochemical diffusion | Creates a stable, predictable carbide lattice structure |

Elevate Your Refractory Metal Processing with KINTEK

Precision is paramount when working with tantalum and carbide structures. KINTEK provides industry-leading Vacuum, CVD, and High-Temperature Muffle Systems specifically engineered to maintain the rigorous $10^{-5}$ Torr environments required for sensitive gas-solid reactions.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to solve your unique thermal processing challenges. Whether you need to optimize stoichiometric uniformity or ensure absolute chemical purity, our lab-grade furnaces offer the control you need.

Ready to refine your carburization process? Contact our technical experts today to find the perfect furnace for your application.

Visual Guide

References

- Seon-Min Hwang, Dong‐Won Lee. Carburization of Tantalum Metal Powder Using Activated Carbon. DOI: 10.3390/ma18122710

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What high-temperature applications do vacuum furnaces serve? Unlock Purity and Precision in Advanced Manufacturing

- What gas is used in graphite furnace? Argon vs. Nitrogen for Optimal GF-AAS Performance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What is the purpose of the hot zone in a vacuum furnace and what materials are commonly used for heat shielding? Optimize Your High-Temp Processes

- What temperature range can a vacuum furnace operate at? Find the Perfect Fit for Your Materials

- How does vacuum hardening affect the hardness and surface layer of high-alloy tool steel? Boost Performance with Superior Heat Treatment

- What role does a vacuum oven play in delta-MnO2 electrode processing? Stabilize and Protect Your Active Materials

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures