In short, vacuum hardening significantly enhances high-alloy tool steel by creating a harder, more uniform surface layer than conventional methods. This is achieved by forming a thin, micro-carburized layer during the oil quench, a unique benefit of the process that also eliminates common defects like oxidation and quenching soft spots.

The true value of vacuum hardening is not just the hardness it achieves, but the unparalleled control and consistency it provides. By creating a chemically pure environment, it allows the steel to reach its maximum theoretical properties without the surface degradation common in atmospheric heat treatments.

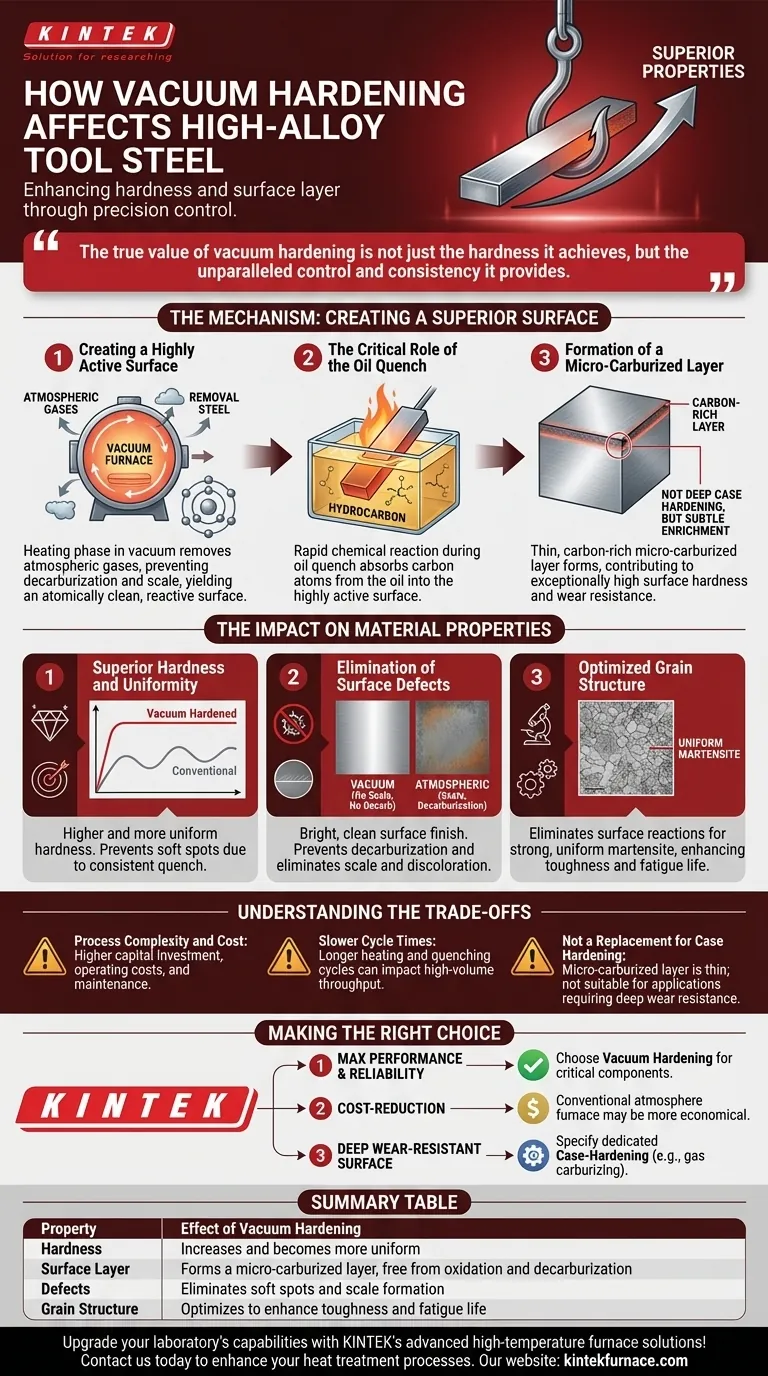

The Mechanism: How Vacuum Hardening Creates a Superior Surface

The unique benefits of vacuum hardening stem from the controlled environment it creates, which fundamentally changes how the steel reacts during heating and quenching.

Creating a Highly Active Surface

During the heating phase, the vacuum furnace removes nearly all atmospheric gases, particularly oxygen. This prevents the formation of an oxide scale layer (decarburization) that typically forms on the steel's surface in a conventional furnace.

The resulting surface is atomically clean and therefore chemically "active" or highly reactive.

The Critical Role of the Oil Quench

When this highly active steel part is submerged in quenching oil (which is a hydrocarbon), a rapid chemical reaction occurs on its surface.

The heat and reactivity of the steel cause carbon atoms from the oil to be instantly absorbed into the steel's surface lattice.

Formation of a Micro-Carburized Layer

This absorption of carbon forms an extremely thin, carbon-rich layer. This is not a deep case-hardening process, but rather a subtle surface enrichment.

This micro-carburized layer is a key contributor to the exceptionally high surface hardness and wear resistance seen in vacuum-hardened components.

The Impact on Material Properties

The combination of a clean environment and surface carburization results in measurable improvements over traditional hardening methods.

Superior Hardness and Uniformity

The process yields a component with higher and more uniform hardness. The clean surface ensures a consistent and rapid heat transfer during the quench, preventing the formation of "soft spots" that can occur from uneven cooling.

The additional carbon on the surface boosts the hardness value beyond what the base alloy alone could achieve.

Elimination of Surface Defects

Vacuum hardening produces parts with a bright, clean surface finish, free from the scale and discoloration typical of atmospheric hardening. This often reduces or eliminates the need for post-treatment cleaning or grinding.

It completely prevents surface decarburization (loss of carbon), which is a common failure point that creates a soft, weak skin on parts hardened in atmosphere furnaces.

Optimized Grain Structure

By eliminating unwanted surface reactions, the process allows the steel's internal grain structure to transform into strong, uniform martensite as intended. This optimized structure enhances not just hardness but also the overall toughness and fatigue life of the tool steel.

Understanding the Trade-offs

While powerful, vacuum hardening is not the universal solution for all applications. Its benefits must be weighed against its practical considerations.

Process Complexity and Cost

Vacuum furnaces represent a significant capital investment and have higher operating costs compared to conventional atmosphere furnaces. They require specialized operators and stricter maintenance protocols.

Slower Cycle Times

The process of pulling a vacuum, heating, and executing a controlled quench cycle can be longer than that of a standard furnace. This can impact high-volume production throughput.

Not a Replacement for Case Hardening

The micro-carburized layer is extremely thin and is a beneficial side effect, not a primary goal. It cannot replace dedicated case-hardening processes like gas carburizing or nitriding, which are designed to create a much deeper, wear-resistant case for gears or bearings.

Making the Right Choice for Your Goal

Selecting the right heat treatment method depends entirely on the component's final application and performance requirements.

- If your primary focus is maximum performance and reliability: Choose vacuum hardening for critical components like high-performance dies, molds, and cutting tools where uniform hardness and a defect-free surface are non-negotiable.

- If your primary focus is cost-reduction for less demanding parts: A conventional atmosphere furnace is often a more economical choice, provided some post-processing like shot-blasting or grinding is acceptable.

- If your primary focus is a deep, highly wear-resistant surface: You should specify a dedicated case-hardening process, as the surface effect from vacuum hardening is not sufficient for extreme wear applications.

Ultimately, choosing vacuum hardening is an investment in superior material properties and process repeatability for your most demanding applications.

Summary Table:

| Property | Effect of Vacuum Hardening |

|---|---|

| Hardness | Increases and becomes more uniform |

| Surface Layer | Forms a micro-carburized layer, free from oxidation and decarburization |

| Defects | Eliminates soft spots and scale formation |

| Grain Structure | Optimizes to enhance toughness and fatigue life |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Whether you're working with high-alloy tool steels or other materials, our furnaces ensure precise control and superior results. Contact us today to discuss how we can enhance your heat treatment processes and boost your productivity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today