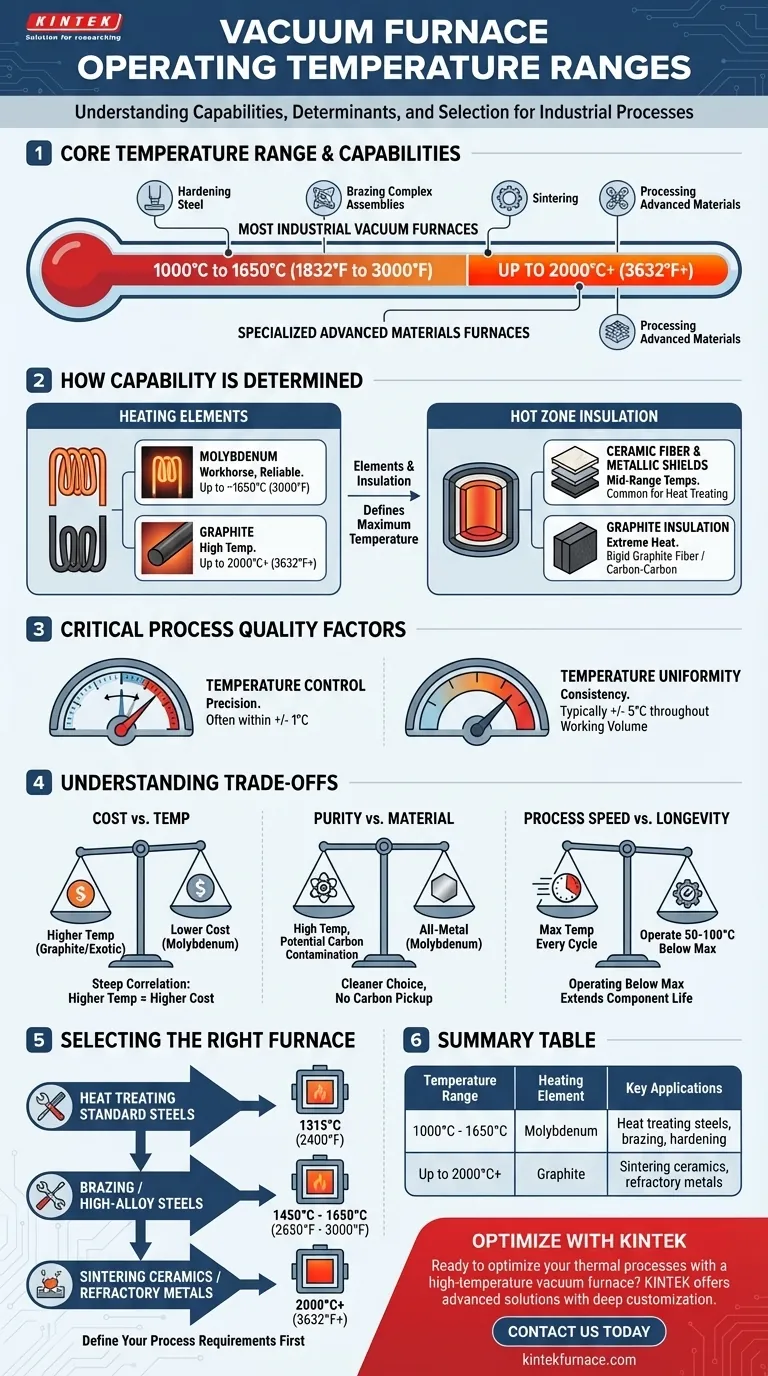

In short, most industrial vacuum furnaces operate within a temperature range of 1000°C to 1650°C (1832°F to 3000°F). While this covers a vast number of applications, from hardening steel to brazing complex assemblies, specialized furnaces designed for advanced materials can achieve temperatures of 2000°C (3632°F) and beyond.

The specific temperature range of a vacuum furnace is not a single standard but is determined by its design and intended application. The crucial factor is matching the furnace's capability—defined by its heating elements and insulation—to the precise thermal process your material requires.

How a Furnace's Temperature Capability is Determined

The maximum operating temperature of a vacuum furnace is not an arbitrary number. It is a direct result of fundamental design choices and the physical limitations of its core components.

The Role of Heating Elements

The material used for the heating elements is the primary factor defining the furnace's peak temperature.

- Molybdenum: This is the workhorse for a majority of vacuum furnaces. Molybdenum elements are reliable and cost-effective for processes up to approximately 1650°C (3000°F).

- Graphite: For applications requiring higher temperatures, graphite elements are used. These are common in furnaces designed for sintering and processing advanced materials, enabling operating temperatures of 2000°C (3632°F) or higher.

The Importance of the Hot Zone Insulation

The "hot zone" is the insulated chamber that contains the heat. The insulation package must be able to withstand the temperatures generated by the elements.

- Ceramic Fiber & Metallic Shields: Common insulation packages use layers of ceramic fiber and metallic heat shields (often molybdenum or stainless steel). These are effective for the mid-range temperatures used in most heat treating.

- Graphite Insulation: Furnaces built for very high temperatures typically use rigid graphite fiber or carbon-carbon composite insulation, which can handle the extreme heat generated by graphite elements.

The Critical Difference: Control vs. Uniformity

Beyond maximum temperature, two other specifications are critical for process quality.

- Temperature Control: This refers to how precisely the furnace can hit and hold a target temperature setpoint. Modern systems offer exceptional control, often within +/- 1°C.

- Temperature Uniformity: This measures the temperature variation across the entire working volume of the hot zone. A typical specification is +/- 5°C, ensuring that a large part or a full batch of small parts receives the exact same thermal treatment.

Understanding the Trade-offs

Selecting a furnace based on temperature is not as simple as choosing the highest number. Higher performance comes with significant trade-offs in cost, maintenance, and operational flexibility.

Higher Temperature vs. Cost

There is a direct and steep correlation between maximum operating temperature and cost. The exotic materials required for high-temperature heating elements (graphite) and insulation are significantly more expensive than standard molybdenum components.

Purity vs. Material

Graphite heating elements, while capable of higher temperatures, can be a source of carbon contamination. For processes where carbon pickup is detrimental to the material being treated, a lower-temperature all-metal furnace with molybdenum elements is the superior, cleaner choice.

Process Speed vs. Longevity

Pushing a furnace to its absolute maximum temperature limit for every cycle will drastically reduce the lifespan of its heating elements and insulation. Operating at 50-100°C below the rated maximum significantly extends component life and reduces long-term maintenance costs.

Selecting the Right Furnace for Your Process

Your decision should be driven entirely by the materials you are processing and the thermal cycle they require.

- If your primary focus is heat treating standard steels: A furnace capable of 1315°C (2400°F) will cover most hardening, tempering, and annealing needs.

- If your primary focus is brazing or processing high-alloy/tool steels: Target a furnace with a maximum temperature of at least 1450°C to 1650°C (2650°F to 3000°F).

- If your primary focus is sintering ceramics or processing refractory metals: You will require a specialized high-temperature furnace, likely with graphite elements, capable of reaching 2000°C (3632°F) or more.

Ultimately, defining your process requirements first is the only reliable way to determine the correct furnace temperature specification.

Summary Table:

| Temperature Range | Heating Element | Key Applications |

|---|---|---|

| 1000°C - 1650°C | Molybdenum | Heat treating steels, brazing, hardening |

| Up to 2000°C+ | Graphite | Sintering ceramics, refractory metals |

Ready to optimize your thermal processes with a high-temperature vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today