In the world of high-temperature vacuum furnaces, the most significant innovations in graphite are not about replacing this critical material, but about strategically enhancing it. The key advancements center on two areas: the application of protective coatings to dramatically extend component life and the custom engineering of graphite parts to optimize performance for specific processes. These innovations allow operators to push the boundaries of efficiency and durability.

While graphite is already the industry standard for its high-temperature resilience, modern advancements focus on overcoming its operational limitations. By applying specialized coatings and tailoring component designs, you can transform standard graphite into a high-performance, long-lasting asset that boosts furnace uptime and process quality.

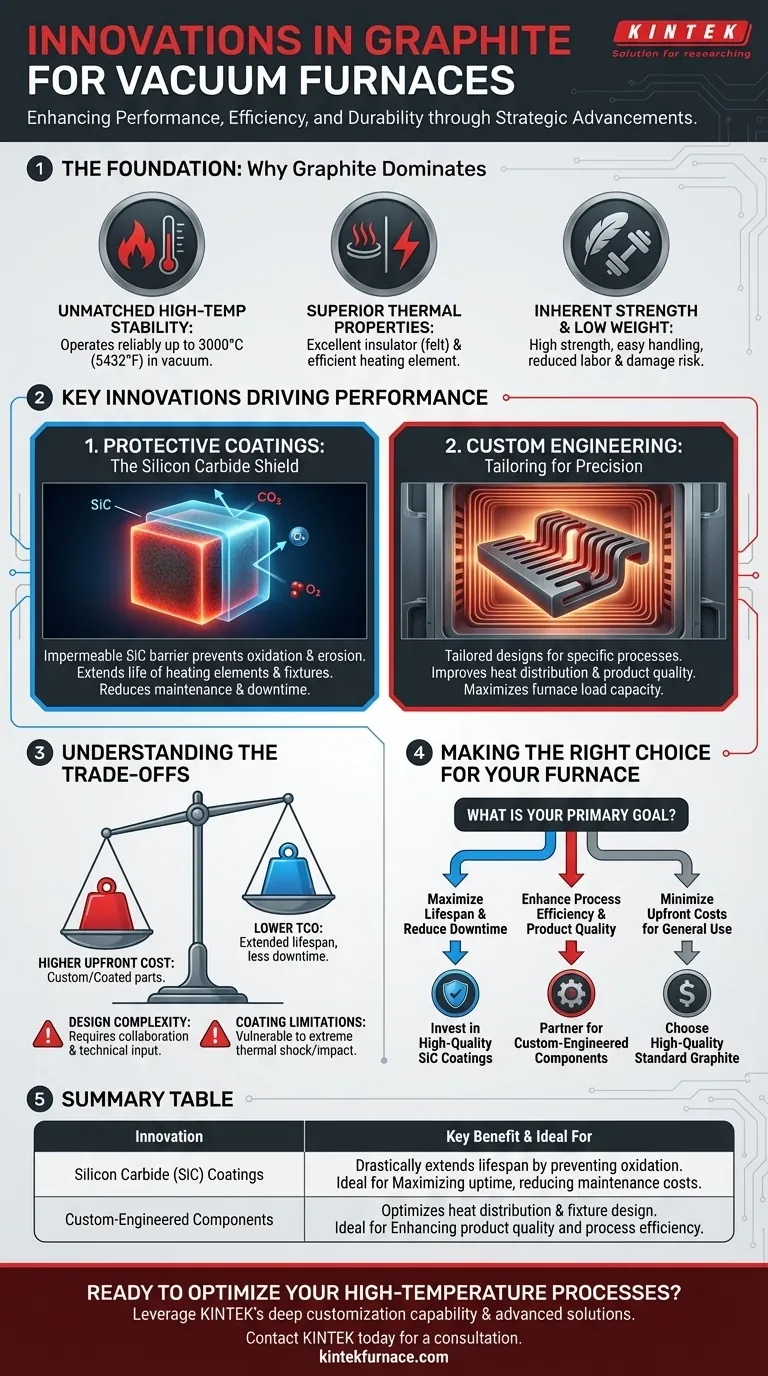

The Foundation: Why Graphite Dominates Vacuum Furnaces

Before examining the innovations, it's crucial to understand why graphite is the material of choice for furnace components like heating elements, fixtures, and insulation.

Unmatched High-Temperature Stability

Graphite's primary advantage is its ability to maintain its structural integrity and strength at extreme temperatures. It can operate reliably up to 3000°C (5432°F) in a vacuum or inert gas atmosphere, far surpassing the limits of most metals.

Superior Thermal Properties

Graphite's thermal behavior is uniquely suited for furnace applications. As an insulator, graphite felt offers excellent heat retention and is lightweight and easy to install. As a conductor, graphite's low electrical resistivity allows it to function as a highly efficient heating element, generating uniform heat when an electric current is applied.

Inherent Strength and Low Weight

Despite its high strength, graphite is remarkably lightweight. This makes larger components, such as fixtures and tooling, easier and more economical to handle and install, reducing both labor costs and the risk of damage during maintenance.

Key Innovations Driving Performance

The latest advancements target the weak points of graphite, such as its susceptibility to oxidation or its "one-size-fits-all" nature in standard components.

Protective Coatings: The Silicon Carbide Shield

One of the most impactful innovations is the use of silicon carbide (SiC) based coatings. Uncoated graphite can degrade over time due to reactions with trace oxygen or water vapor present even in a high-vacuum environment.

A dense SiC coating acts as an impermeable barrier on the graphite's surface. This shield prevents oxidation and erosion, drastically extending the life of expensive components like heating elements and custom fixtures. This leads directly to less frequent replacement, reduced maintenance downtime, and more consistent furnace performance.

Custom Engineering: Tailoring Graphite for Precision

The second major innovation is the move away from generic, off-the-shelf parts toward custom-designed graphite components. Standard parts are made for general use, but every heat-treating, brazing, or sintering process has unique requirements.

By tailoring the design of a component to a specific furnace and process, you can achieve significant gains. Custom heating elements can be shaped to provide more uniform heat distribution in the hot zone, improving product quality. Custom-designed fixtures can securely hold complex parts, minimizing distortion and maximizing furnace load capacity. This approach turns a basic material into a precision-engineered tool.

Understanding the Trade-offs

While these innovations offer clear advantages, they require a shift in mindset from simply purchasing a commodity to investing in a strategic asset.

The Cost of Innovation

Custom-engineered and coated graphite components carry a higher upfront cost than standard, uncoated parts. The justification for this investment lies in the Total Cost of Ownership (TCO). The extended lifespan and improved process efficiency often deliver a significant return by reducing costly downtime and increasing product yield over time.

Design and Specification Complexity

Opting for custom-designed parts requires a deeper understanding of your own process requirements. It involves a collaborative effort with your graphite supplier to engineer a solution. This demands more upfront time and technical input compared to ordering a standard part from a catalog.

Coating Limitations

While highly effective, protective coatings have their own vulnerabilities. They can be brittle and may be susceptible to cracking if subjected to extreme thermal shock or mechanical impact. The success of a coating depends heavily on the quality of its application and its compatibility with the specific thermal cycles of your furnace.

Making the Right Choice for Your Furnace

Selecting the right graphite solution depends entirely on your primary operational goal.

- If your primary focus is maximizing component lifespan and reducing downtime: Invest in high-quality silicon carbide coatings for your critical graphite components.

- If your primary focus is enhancing process efficiency and product quality: Partner with a supplier to develop custom-engineered heating elements and fixtures tailored to your specific application.

- If your primary focus is minimizing upfront costs for general-purpose applications: High-quality, standard graphite components remain the most economical and effective choice.

Ultimately, these innovations empower you to treat graphite not as a simple consumable, but as a strategic lever for optimizing your high-temperature processes.

Summary Table:

| Innovation | Key Benefit | Ideal For |

|---|---|---|

| Silicon Carbide (SiC) Coatings | Drastically extends component lifespan by preventing oxidation | Maximizing uptime, reducing maintenance costs |

| Custom-Engineered Components | Optimizes heat distribution and fixture design for specific processes | Enhancing product quality and process efficiency |

Ready to optimize your high-temperature processes?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let our experts help you select or custom-design the perfect graphite components—whether coated for extreme durability or engineered for peak performance—to boost your furnace's efficiency and productivity.

Contact KINTEK today for a consultation and discover the strategic advantage of high-performance graphite!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the benefits of using vacuum furnaces for heat treating compared to traditional methods? Achieve Superior Quality and Control

- How do heat treatment and vacuum furnaces contribute to industrial innovation? Unlock Superior Material Performance

- What are the advantages of using graphite as a heating element in vacuum furnaces? Achieve Extreme Heat with Superior Stability

- Why is vacuum heat treatment necessary? Achieve Superior Material Purity and Performance

- What benefits does vacuum carburizing offer for parts with complex shapes? Minimize Distortion and Boost Performance

- How can rapid cooling (quenching) benefit the process in a vacuum furnace? Boost Efficiency and Material Properties

- What are the technical challenges of SEM in-situ furnaces? Optimize High-Temperature Dynamic Observation

- What are the advantages of a Vertical/Bottom Loading Vacuum Furnace? Save Space and Boost Precision