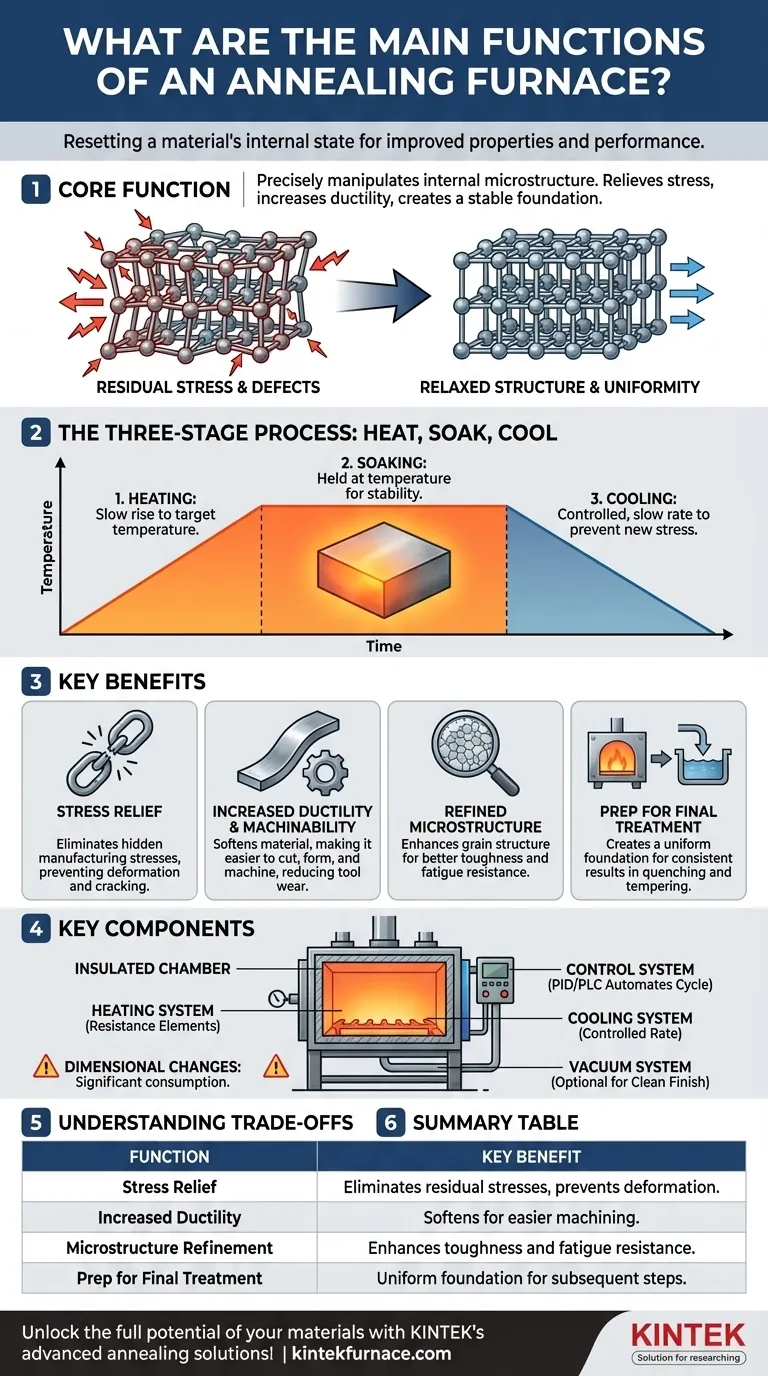

At its core, an annealing furnace is a tool for resetting a material's internal state. Its primary functions are to improve or eliminate structural defects and residual stresses introduced during manufacturing, soften the material to make it easier to cut, refine its internal grain structure to enhance mechanical properties, and prepare the material for subsequent heat treatments. This controlled process of heating and cooling is fundamental to achieving desired performance and reliability in metal components.

An annealing furnace's true purpose is not merely to heat metal, but to precisely manipulate its internal microstructure. This manipulation relieves stress, increases ductility, and creates a uniform, predictable foundation for all subsequent manufacturing steps.

The Science of Annealing: From Stressed to Stable

To understand the functions of an annealing furnace, you must first understand the process it facilitates. Annealing is a three-stage heat treatment designed to alter a material's physical and sometimes chemical properties.

The Three-Stage Process: Heat, Soak, Cool

The entire process is defined by precise control over temperature and time.

- Heating: The material is slowly heated to a specific temperature. The target temperature depends on the material and the desired outcome.

- Soaking: The material is held at this temperature for a set period, allowing the internal structure to stabilize and for temperature to distribute uniformly.

- Cooling: The material is cooled at a predetermined, often very slow, rate. This slow cooling is critical to prevent new stresses from forming.

Relieving Internal Stress

Processes like casting, forging, rolling, and welding create immense stress within a material's crystal lattice. These hidden stresses can lead to unexpected deformation or cracking long after the manufacturing is complete.

Annealing provides the thermal energy necessary for the atoms to rearrange themselves into a lower-energy, more stable configuration, effectively "relaxing" the material and eliminating these residual stresses.

Increasing Ductility and Machinability

A direct result of stress relief and microstructural change is softening. The annealing process increases a material's ductility (its ability to deform without fracturing) and reduces its hardness.

This makes the workpiece significantly easier to machine, cut, or form in subsequent operations, reducing tool wear and improving processing efficiency.

Refining the Microstructure

On a microscopic level, annealing refines the material's grain structure. The heating and soaking phases allow new, strain-free crystals (grains) to form and grow.

Controlling this recrystallization process can create a finer, more uniform grain structure, which typically enhances key mechanical properties like toughness and fatigue resistance.

Preparing for Final Treatment

For many high-performance components, annealing is not the final step. It serves as a crucial preparatory stage for other heat treatments like quenching (rapid cooling to harden) and tempering (low-temperature heating to reduce brittleness).

By creating a homogenous and predictable microstructure, annealing ensures that these final treatments will produce consistent and reliable results across the entire workpiece.

A Look Inside the Furnace: Key Components

The effectiveness of the annealing process depends on the precise control enabled by the furnace's hardware. While designs vary, most industrial annealing furnaces share a common set of systems.

The Furnace Chamber and Heating System

The heart of the furnace is an insulated chamber, often lined with high-performance ceramic fiber, graphite, or molybdenum. The heat is generated by electric resistance elements (like heating wires or silicon carbide rods) that are capable of reaching and maintaining precise temperatures.

The Control System

Modern furnaces rely on sophisticated PID (Proportional-Integral-Derivative) or PLC (Programmable Logic Controller) systems. These controllers automate the entire heat-soak-cool cycle, ensuring the temperature and timing follow the exact specifications required for the material.

The Cooling System

The cooling stage is just as critical as the heating. Some processes allow for slow cooling in still air, while others require more controlled methods like using circulating inert gas or integrated water-cooling jackets to achieve a specific cooling rate.

The Vacuum System (for Specialized Applications)

Many advanced applications use a vacuum annealing furnace. By removing air and creating a vacuum, this system prevents surface oxidation and discoloration, resulting in a "bright" finish. It is essential for materials like stainless steel, medical implants, and high-purity metals.

Understanding the Trade-offs

While powerful, annealing is a process with clear operational considerations that must be weighed.

Time and Energy Costs

Annealing is not an instantaneous process. The slow heating, long soaking times, and controlled cooling cycles consume significant time and energy, representing a primary operational cost.

Risk of Over-Softening

The goal is often to soften the material, but it is possible to go too far. Excessive annealing can reduce a material's strength and hardness below the minimum required for its intended application. Precision is key.

Dimensional Changes

Heating and cooling metal will cause it to expand and contract. While annealing relieves stress, the process itself can cause slight dimensional changes that must be accounted for in high-precision manufacturing.

Making the Right Choice for Your Goal

The decision to use an annealing furnace should be driven by a clear engineering objective.

- If your primary focus is processability: Use annealing to soften materials after forging or casting, making them easier to machine and shape.

- If your primary focus is structural integrity: Employ annealing to eliminate residual stresses from welding or forming, preventing future cracking or warping.

- If your primary focus is performance enhancement: Anneal to refine the grain structure, which improves the material's overall mechanical properties like toughness.

- If your primary focus is consistency in final parts: Use annealing as a preparatory step to create a uniform microstructure before a final heat treatment like quenching.

By mastering the annealing process, you gain precise control over a material's final properties and performance.

Summary Table:

| Function | Key Benefit |

|---|---|

| Stress Relief | Eliminates residual stresses from manufacturing to prevent deformation and cracking |

| Increased Ductility | Softens material for easier machining and forming, reducing tool wear |

| Microstructure Refinement | Enhances grain structure for better toughness and fatigue resistance |

| Preparation for Final Treatment | Creates uniform foundation for processes like quenching and tempering |

Unlock the full potential of your materials with KINTEK's advanced annealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering reliable performance and efficiency. Ready to enhance your heat treatment processes? Contact us today for a tailored consultation!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of using multi-stage programmed heating for copper-iron sintering? Enhance Material Integrity

- How does a vertical vacuum furnace facilitate MgB2 wire fabrication? Master Internal Magnesium Coating Processes

- What role does a high-vacuum heat treatment furnace play in the preparation of a GdEuZrO/YSZ double-layer coating system?

- What technical problems are addressed by using a tempering furnace for bearing steel? Achieve Peak Stability.

- How do the structural features of a box furnace and a vacuum furnace differ? Compare for Your Lab's Needs

- How does Diamond Burnishing (DB) and Low-Temperature Gaseous Nitriding (LTGN) improve material output?

- Why is a Teflon lining required for high-pressure autoclaves? Ensure Purity in High-Entropy Oxide Synthesis

- What is the recommended solution to prevent graphite oxidation in vacuum furnaces? Maintain a Pure, Oxygen-Free Environment