In essence, using a vacuum or controlled atmosphere in a sintering furnace provides unparalleled control over the process, resulting in superior material quality and consistency. By removing reactive gases like oxygen, these furnaces prevent contamination and oxidation, which is critical for processing sensitive materials and achieving desired final properties.

The core benefit is not merely the absence of air, but the creation of an ultrapure, highly controllable environment. This level of control translates directly into higher-quality parts, repeatable outcomes, and greater operational efficiency.

Achieving Superior Material Quality and Purity

The primary driver for using a vacuum or controlled atmosphere is to directly influence the metallurgical properties of the final product. This is achieved by managing the chemical environment at every stage.

Eliminating Oxidation and Contamination

A vacuum environment is the most effective way to remove oxygen and other atmospheric contaminants. This prevents the formation of unwanted oxides on the surface of the powder particles, which would otherwise inhibit proper bonding during sintering.

For materials that are highly sensitive to oxygen, such as titanium, certain stainless steels, and refractory metals, a vacuum is not just beneficial—it is essential.

Ensuring Structural Uniformity

Modern vacuum furnaces feature advanced temperature control and optimized heating elements. This ensures a highly uniform temperature throughout the heating zone.

This thermal consistency guarantees that all parts in a batch are sintered under the exact same conditions, leading to uniform density, grain structure, and mechanical properties across the entire load.

Enabling High-Temperature Processing

Vacuum furnaces are engineered for high-temperature applications. Superior insulation, often using graphite or advanced ceramics, minimizes heat loss and allows the furnace to reach and maintain the extreme temperatures required for sintering high-performance materials.

Gaining Unmatched Process Control and Repeatability

Beyond purity, these furnaces offer a level of programmable control that makes the sintering process a precise, repeatable science rather than a variable art.

Precision Parameter Adjustment

Operators can precisely program and control critical process parameters. This includes the exact vacuum level, the heating and cooling rates, and the duration of holds at specific temperatures.

This allows for the development of "recipes" tailored to specific materials and desired outcomes, which can then be executed identically for every batch, ensuring perfect repeatability.

Advanced Automation and Safety

Intelligent control systems automate the entire sintering cycle, reducing the need for manual intervention and minimizing the chance of human error.

These systems also integrate critical safety interlocks, such as alarms for over-temperature, over-current, or loss of cooling water, protecting both the equipment and the personnel.

Faster Cooling Cycles

Many vacuum furnaces incorporate a gas quenching function. This feature allows for the introduction of an inert gas, like argon or nitrogen, at the end of the cycle to rapidly and controllably cool the parts. This can significantly shorten cycle times and improve overall productivity.

Understanding the Operational and Economic Advantages

While the initial investment may be higher, vacuum furnaces are designed for long-term efficiency and a lower total cost of ownership.

Reduced Energy Consumption

By using advanced insulation materials and operating within a closed, thermally efficient system, vacuum furnaces minimize heat loss. This directly translates to lower energy consumption per cycle compared to less advanced furnace designs.

Lower Maintenance and Operating Costs

A robust, modular design simplifies maintenance and troubleshooting. Because the process is contained, there are no exhaust gases or wastewater to manage, which lowers environmental compliance costs and creates a cleaner, safer workplace.

Enhanced Environmental Profile

The sealed vacuum environment inherently prevents the release of process fumes or byproducts into the atmosphere. This helps facilities meet stringent environmental regulations and improves workplace safety by containing potentially hazardous materials.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your specific material and quality requirements.

- If your primary focus is material purity and performance: A vacuum furnace is non-negotiable for preventing oxidation in sensitive materials and achieving the highest possible density and strength.

- If your primary focus is process consistency and repeatability: The precise, automated control over temperature, pressure, and cycle time ensures that every batch meets the exact same specification.

- If your primary focus is long-term operational efficiency: The energy savings, reduced maintenance, and improved cycle times of a modern vacuum furnace provide a strong return on investment for high-volume production.

Ultimately, investing in a vacuum or controlled atmosphere furnace is an investment in process control, which is the foundation of manufacturing high-quality, high-performance components.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Material Quality | Eliminates oxidation and contamination, ensures structural uniformity, enables high-temperature processing |

| Process Control | Precision parameter adjustment, advanced automation, faster cooling cycles for repeatability |

| Operational Efficiency | Reduced energy consumption, lower maintenance costs, enhanced environmental profile |

Ready to elevate your sintering process with precision and reliability? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored furnace solutions can enhance your material quality, improve repeatability, and reduce operational costs!

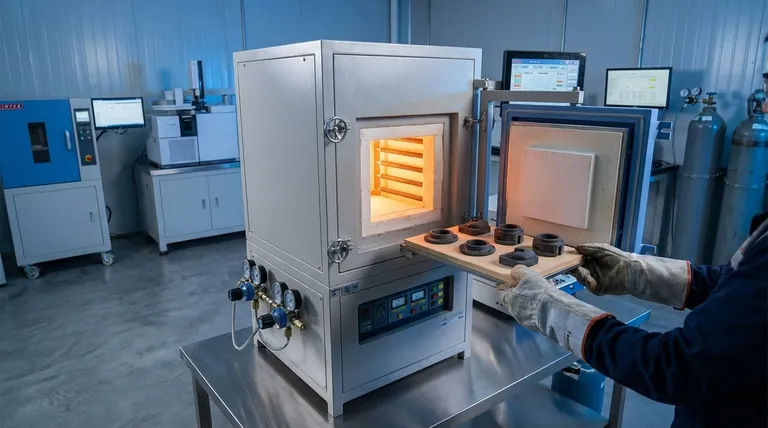

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments