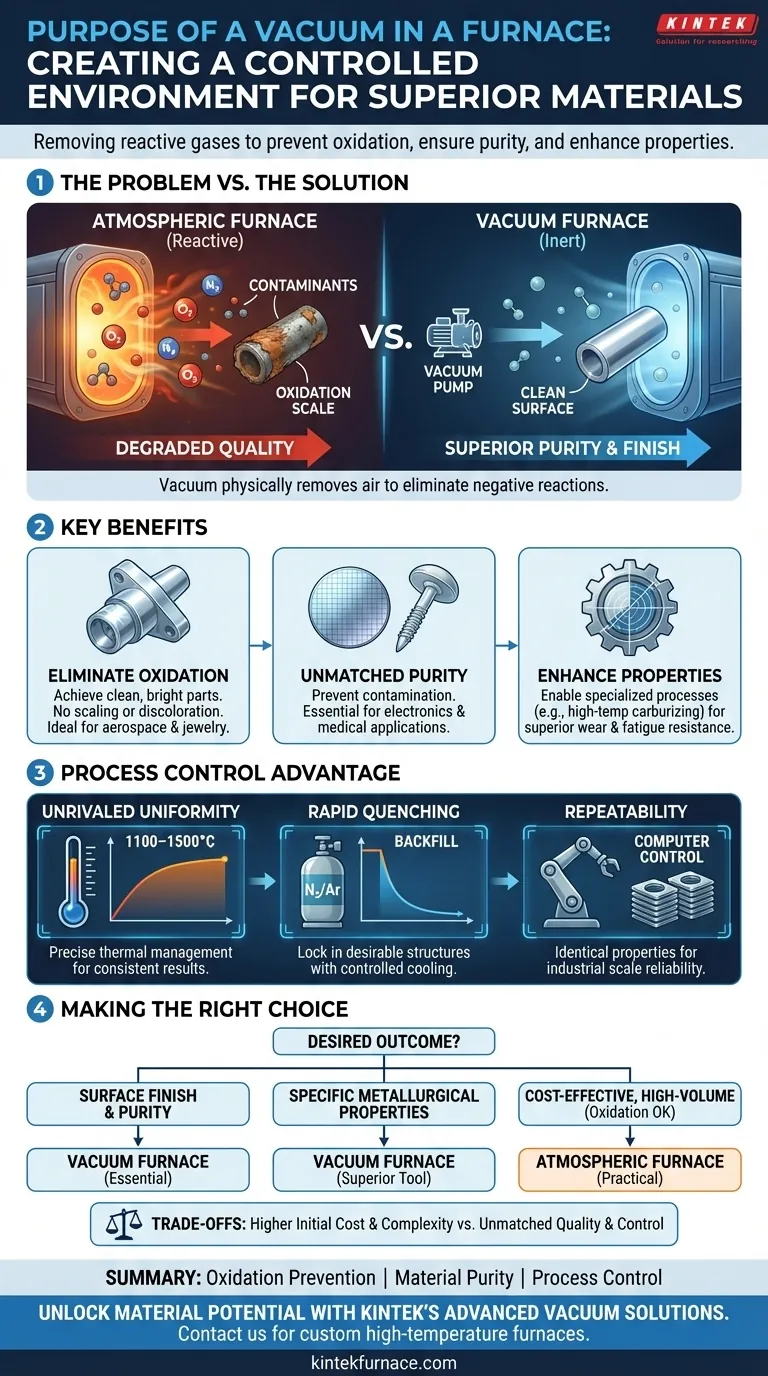

At its core, the purpose of using a vacuum in a furnace is to remove the reactive gases found in air—primarily oxygen and nitrogen. By creating a low-pressure environment, the furnace protects heated materials from oxidation and other unwanted chemical reactions that degrade their quality and performance.

The fundamental role of a vacuum is to transform the furnace from a simple heater into a highly controlled environment. This isn't just about preventing damage like rust; it's about enabling the creation of materials with superior purity, specific properties, and unmatched consistency.

The Problem: Atmosphere as a Contaminant

Why Normal Air Is Harmful at High Temperatures

When metals are heated in a normal atmosphere, the oxygen present reacts with their surface. This process, known as oxidation, creates a layer of scale or discoloration that must be cleaned off later, wasting material and time.

Other gases in the air can also cause issues. For example, they can lead to contamination of the product, altering its chemical makeup and compromising its final properties.

The Vacuum Solution: Creating an Inert Environment

A vacuum furnace solves this by physically removing the air before the heating process begins. By pumping the atmosphere out of the sealed chamber, the potential for these negative reactions is virtually eliminated.

This creates an extremely clean, inert environment where the heat treatment process can be executed without any unintended influence from atmospheric gases.

Key Benefits of a Vacuum Environment

Eliminating Oxidation for a Superior Surface Finish

The most immediate benefit is a clean, bright part right out of the furnace. Since there's no oxygen to cause scaling, parts retain their original metallic luster.

This is critical in industries like aerospace and jewelry manufacturing, where surface integrity and appearance are paramount, and post-processing steps like chemical cleaning or sandblasting are undesirable.

Achieving Unmatched Material Purity

By removing the atmosphere, you prevent gases like oxygen and carbon from contaminating the material. This allows for the production of extremely pure metals and alloys.

This level of purity is essential for high-performance applications in electronics, medical implants, and advanced material science research.

Enhancing Specific Material Properties

A vacuum allows for specialized processes that fine-tune a material's characteristics. For instance, high-temperature carburizing can be performed faster and more effectively.

Without oxygen, there is no internal oxidation in the carburized layer, resulting in superior fatigue life and wear resistance—properties that are impossible to achieve in a conventional furnace.

Beyond Purity: The Advantage of Process Control

Unrivaled Temperature Uniformity

Vacuum furnaces are engineered for exceptional thermal management, often providing uniform temperatures in ranges of 1100–1500°C (2000–2800°F).

Advanced insulation and control systems minimize heat loss, ensuring that the entire part receives the exact same thermal treatment. This precision is key to achieving consistent results.

Rapid Cooling (Quenching) Capabilities

Many vacuum furnaces allow for rapid cooling by backfilling the chamber with an inert gas like nitrogen or argon. This quenching process locks in the desirable metallurgical structure created during heating.

This ability to control both the heating and cooling cycles with high precision gives engineers enormous control over the final hardness, strength, and durability of a material.

Ensuring Metallurgical Repeatability

Because the entire process—from pumping down the vacuum to heating and quenching—is often computer-controlled, the results are highly repeatable.

For industrial manufacturing, this means every part in a batch, and every batch over time, will have the identical properties, ensuring reliability and quality at scale.

Understanding the Trade-offs

Higher Initial Cost and Complexity

Vacuum furnaces are more complex and expensive to build and maintain than standard atmospheric furnaces. The vacuum pumps, seals, and advanced control systems represent a significant investment.

Slower Cycle Times in Some Cases

The need to pump the chamber down to a vacuum level adds time to the beginning of each cycle. For some high-volume, low-spec applications, this can be a drawback compared to a continuous atmospheric furnace.

Not Always Necessary

For simple annealing or tempering where a layer of surface oxide is acceptable or easily removed, the expense and complexity of a vacuum furnace may not be justified. The tool must match the requirements of the job.

Making the Right Choice for Your Goal

Ultimately, the decision to use a vacuum furnace depends on the desired outcome for your material.

- If your primary focus is surface finish and purity: A vacuum furnace is essential to prevent oxidation and deliver clean, bright parts directly from the heat-treating process.

- If your primary focus is achieving specific metallurgical properties: The precise control over atmosphere, temperature, and quenching makes a vacuum furnace the superior tool for developing advanced materials.

- If your primary focus is cost-effective, high-volume treating: A conventional atmospheric furnace may be more practical, provided that surface oxidation is acceptable or can be managed post-process.

Understanding that a vacuum is a tool for control empowers you to select the right process for your specific engineering goal.

Summary Table:

| Key Aspect | Purpose in Vacuum Furnace |

|---|---|

| Oxidation Prevention | Removes oxygen to avoid surface scaling and discoloration |

| Material Purity | Eliminates contaminants for high-purity metals and alloys |

| Process Control | Enables precise temperature and cooling for consistent results |

| Applications | Ideal for aerospace, jewelry, electronics, and medical implants |

Unlock the full potential of your materials with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior purity, enhanced properties, and unmatched consistency. Contact us today to discuss how we can optimize your heat treatment processes and boost your lab's efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity