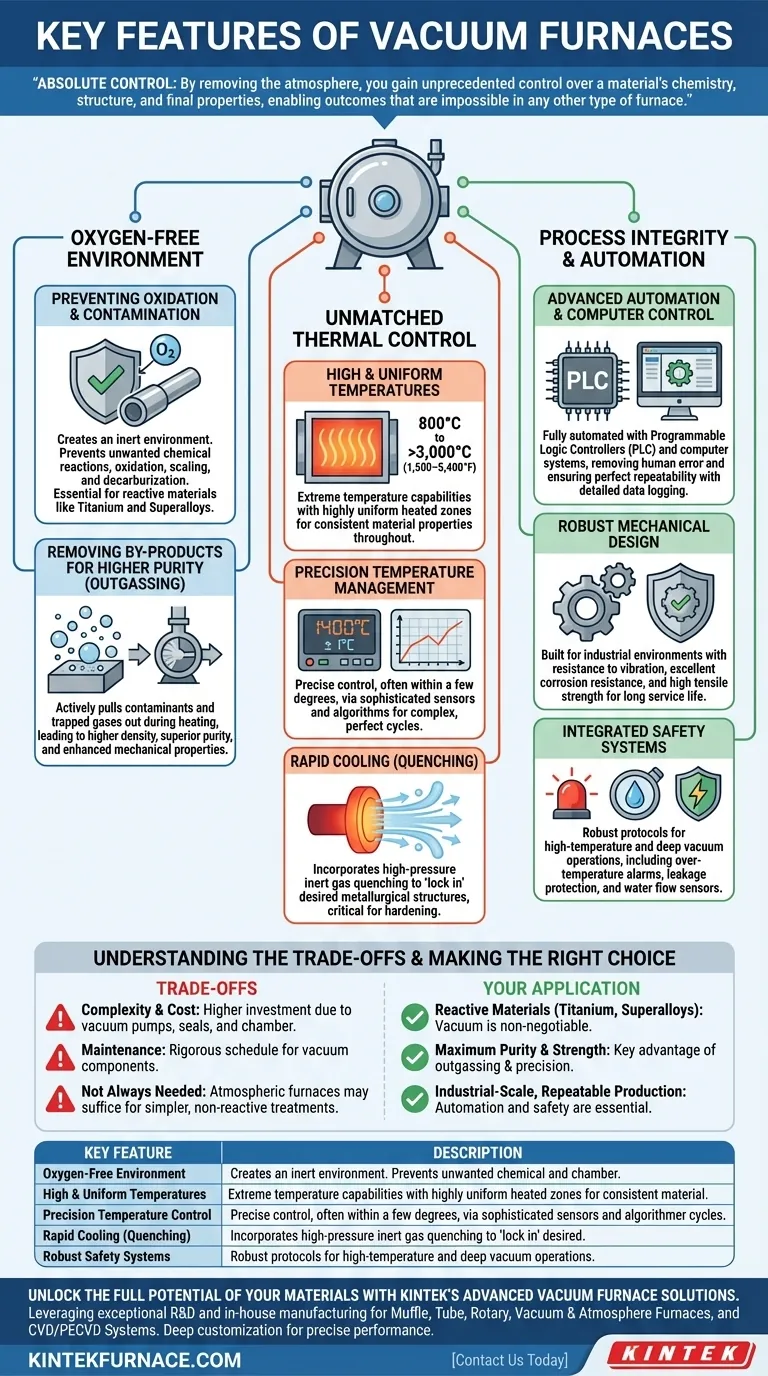

At their core, vacuum furnaces are defined by three primary capabilities. These are the ability to create a controlled, oxygen-free environment through a deep vacuum; the power to achieve extremely high and uniform temperatures with precision; and the capacity for fully automated, computer-controlled processes that ensure perfect repeatability.

The defining feature of a vacuum furnace is not simply heat, but absolute control. By removing the atmosphere, you gain unprecedented control over a material's chemistry, structure, and final properties, enabling outcomes that are impossible in any other type of furnace.

The Core Principle: An Oxygen-Free Environment

The vacuum is the most fundamental feature. By removing air and other gases, the furnace creates an inert environment that prevents unwanted chemical reactions at high temperatures.

Preventing Oxidation and Contamination

At elevated temperatures, most high-performance metals will react with oxygen. This leads to oxidation (rusting), scaling, and decarburization, all of which degrade the material's surface and structural integrity.

A vacuum environment eliminates this risk entirely. This is essential for processing reactive materials like titanium, superalloys, and advanced ceramics, ensuring a clean, bright, and uncompromised surface finish.

Removing By-products for Higher Purity

The vacuum actively pulls contaminants and trapped gases out of the material being processed, a phenomenon known as outgassing.

This process purifies the material by removing unwanted by-products during the heating cycle. The result is a final product with higher density, superior purity, and enhanced mechanical properties.

Unmatched Control Over the Thermal Process

Beyond the vacuum itself, these furnaces provide a level of thermal control that is second to none. This precision allows engineers to dictate the final microstructure of a material.

High and Uniform Temperatures

Vacuum furnaces can operate at extreme temperatures, often ranging from 800°C to over 3,000°C (1,500–5,400°F).

More importantly, they create highly uniform heated zones. This ensures that an entire component, regardless of its geometry, experiences the exact same thermal conditions, leading to consistent and predictable material properties throughout.

Precision Temperature Management

Modern systems offer incredibly precise temperature control, often within a few degrees of the setpoint.

This is managed through sophisticated sensors and computer algorithms, allowing for complex, multi-stage heating cycles to be programmed and executed perfectly every time.

Rapid Cooling (Quenching) Capabilities

Many vacuum furnaces incorporate rapid cooling or quenching systems. After the heating cycle, a high-pressure inert gas can be introduced to cool the part down quickly.

This rapid cooling "locks in" a desired metallurgical structure, which is a critical step for hardening steel or controlling the grain structure in superalloys.

Ensuring Process Integrity and Repeatability

The final set of key features revolves around making the complex process of vacuum heat treatment reliable, safe, and repeatable, especially in industrial settings.

Advanced Automation and Computer Control

Nearly all modern vacuum furnaces are fully automated. Processes are managed by a Programmable Logic Controller (PLC) and computer system.

This electromechanical integration removes human error, guarantees that every part undergoes the exact same treatment cycle, and provides detailed data logging for quality control and certification.

Robust Mechanical Design

These furnaces are built for industrial environments. Key design features include resistance to vibration, excellent corrosion resistance, and materials with high tensile strength. This ensures a long service life and reliable operation.

Integrated Safety Systems

Operating at high temperatures and deep vacuums requires robust safety protocols. Features like over-temperature alarms, water flow sensors for the cooling system, leakage protection, and overvoltage protection are standard. These systems ensure the safety of the operator and the integrity of the equipment.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every heating application. Understanding their context is key to appreciating their value.

Complexity and Cost

The systems required to create and maintain a high vacuum—including pumps, seals, and chamber construction—make these furnaces significantly more complex and expensive than their atmospheric counterparts, such as a simple box furnace.

Maintenance Requirements

The high-performance components, particularly vacuum pumps and seals, require a rigorous and specialized maintenance schedule to ensure they operate at peak efficiency and prevent costly downtime.

Not Always the Right Tool

For simple heat treatments of non-reactive materials where a bit of surface oxidation is acceptable or can be cleaned off later, a standard atmospheric furnace is often a more practical and cost-effective choice.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on your material and your desired outcome.

- If your primary focus is processing high-performance reactive materials (like superalloys or titanium): The oxygen-free vacuum environment is non-negotiable to prevent catastrophic degradation.

- If your primary focus is achieving maximum material purity and strength: The combination of vacuum outgassing and precise thermal control is your key advantage for creating superior components.

- If your primary focus is industrial-scale, repeatable production: The automation, PLC control, and integrated safety systems are essential for quality assurance and efficient operation.

- If your primary focus is basic heat treatment on non-reactive metals: A simpler and more cost-effective atmospheric box furnace is likely the more appropriate tool.

Ultimately, choosing a vacuum furnace is a decision to invest in absolute control over your material's final form and function.

Summary Table:

| Key Feature | Description |

|---|---|

| Oxygen-Free Environment | Prevents oxidation and contamination for reactive materials like titanium and superalloys. |

| High and Uniform Temperatures | Operates from 800°C to over 3,000°C with even heating for consistent results. |

| Precision Temperature Control | Manages temperatures within a few degrees using sensors and computer algorithms. |

| Rapid Cooling (Quenching) | Uses inert gas to quickly cool materials, locking in desired metallurgical structures. |

| Advanced Automation | PLC and computer systems ensure repeatable processes and detailed data logging. |

| Robust Safety Systems | Includes alarms, sensors, and protection mechanisms for operator and equipment safety. |

Unlock the full potential of your materials with KINTEK's advanced vacuum furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure precise performance for industries handling reactive metals, ceramics, and high-purity applications. Contact us today to discuss how we can enhance your lab's efficiency and outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today