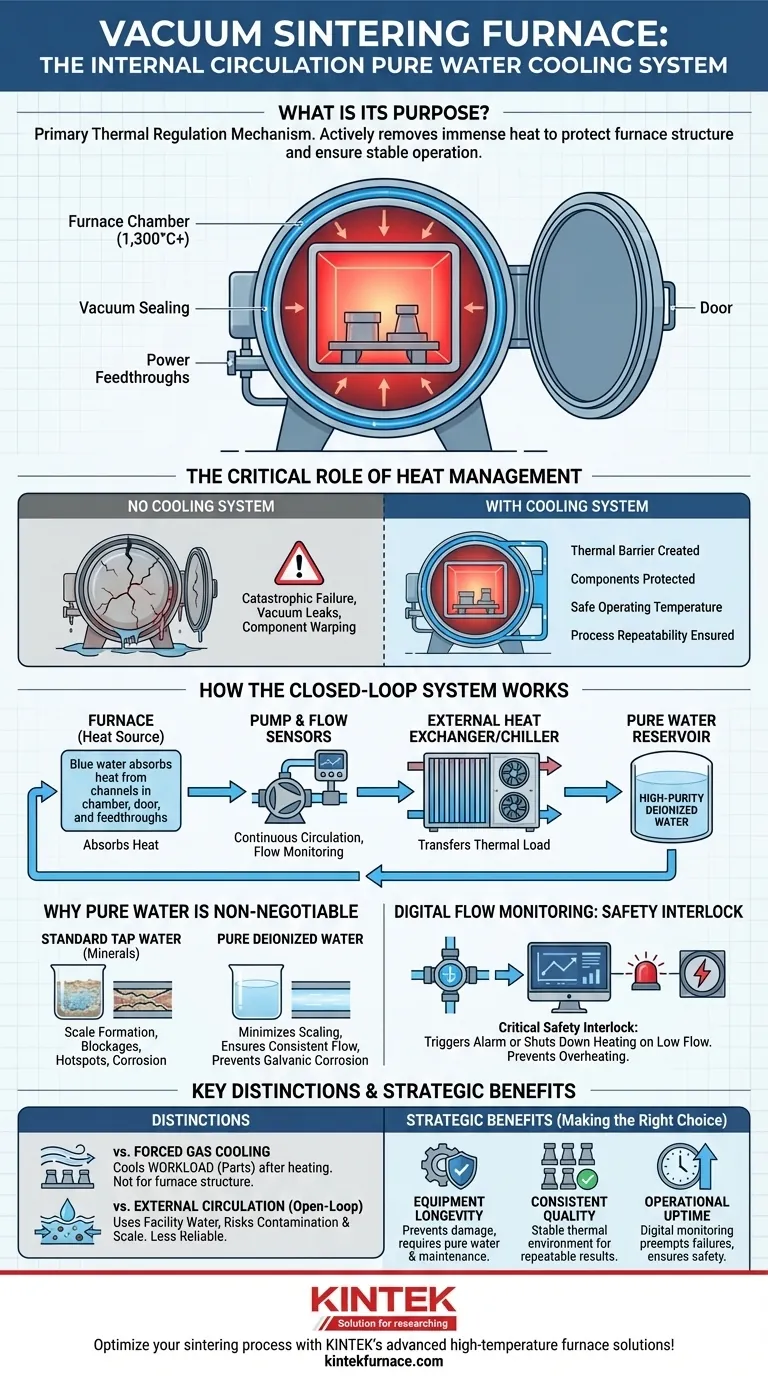

In essence, the internal circulation pure water cooling system is the primary thermal regulation mechanism for a vacuum sintering furnace. It functions by actively removing the immense heat generated during the high-temperature sintering process, thereby protecting the furnace's structural integrity and ensuring the entire operation remains stable and predictable.

The core purpose of this system extends beyond simple cooling. It is a critical process control element that safeguards the furnace from self-destruction while enabling the precise, repeatable thermal conditions necessary to produce high-quality sintered components.

The Critical Role of Heat Management in Sintering

To understand the system, one must first appreciate the hostile environment inside a vacuum furnace. The temperatures required for sintering can easily exceed 1,300°C (2,372°F) or much higher, which is enough to damage or destroy the furnace structure itself if left unchecked.

Why Aggressive Cooling is Necessary

The furnace chamber, seals, and electrical connections are not designed to withstand the full process temperature directly. The cooling system creates a thermal barrier, actively removing heat energy from the furnace walls and other components.

Without this constant heat dissipation, the furnace body would overheat, leading to vacuum leaks, component warping, and ultimately, catastrophic failure.

Protecting Sensitive Components

Specific parts of the furnace are highly vulnerable to thermal damage. The cooling system circulates water through dedicated channels in the furnace's double-walled vacuum chamber, door, and power feedthroughs.

This targeted cooling maintains these components at a safe operating temperature, preserving the integrity of critical O-rings and seals that are essential for maintaining the vacuum.

Ensuring Process Repeatability

The quality of a sintered part is directly dependent on its entire thermal history, including the cooling phase. A stable and efficient cooling system ensures that the temperature environment is consistent from one cycle to the next.

Uncontrolled temperature fluctuations caused by an inefficient cooling system would lead to variations in material density, grain structure, and mechanical properties, making the process unreliable.

How the Internal Circulation System Works

The term "internal circulation" refers to a closed-loop design, which is fundamental to its reliability and effectiveness.

The Closed-Loop Principle

In this design, a finite volume of high-purity water is continuously circulated. The water absorbs heat from the furnace components, flows to an external heat exchanger or chiller, and transfers its thermal load to the ambient air or a secondary water supply.

The now-cool water is then pumped back into the furnace to absorb more heat. This closed loop ensures the fluid remains clean and its properties are consistent.

The Importance of Pure Water

Using pure, deionized water is non-negotiable. Standard tap water contains minerals (like calcium and magnesium) that would precipitate out at high temperatures, forming an insulating scale inside the narrow cooling channels.

This scaling restricts flow, creates dangerous hotspots, and can lead to a complete blockage and system failure. Pure water also minimizes the risk of galvanic corrosion between different metals in the furnace structure.

The Role of Digital Flow Monitoring

Modern furnaces incorporate digital flow sensors and temperature monitors. These are not merely for observation; they are critical safety interlocks.

If the flow rate drops below a safe threshold (indicating a pump failure or blockage), the system will automatically trigger an alarm or shut down the furnace's heating elements to prevent overheating and damage.

Understanding the Trade-offs and Distinctions

The pure water system is one of several cooling methods associated with a vacuum furnace, and it's important to distinguish its role.

Internal Water vs. Forced Gas Cooling

The internal water system's primary job is to cool the furnace structure during operation. In contrast, forced gas cooling is typically used to cool the workload (the parts being sintered) at a controlled rate after the heating cycle is complete.

High-purity gasses like nitrogen or argon are often used for this rapid quenching or controlled cooling of the parts themselves, which is a separate function from protecting the furnace walls.

Internal vs. External Circulation

"Internal circulation" (closed-loop) is the standard for high-performance furnaces. Some older or less critical applications might use "external circulation" (open-loop), which draws water from a facility supply and discharges it after a single pass.

While cheaper upfront, open-loop systems risk introducing contaminants and mineral scale, making them unsuitable for processes requiring high reliability and cleanliness.

Potential Failure Points

The system's reliability hinges on the integrity of its components. A pump failure, a major leak in a hose, or a malfunction in the external chiller can force an immediate and costly shutdown.

This dependency underscores why robust preventative maintenance schedules and a reliable monitoring system are absolutely essential for any facility running these furnaces.

Making the Right Choice for Your Operation

Understanding the cooling system's function directly impacts operational strategy, maintenance priorities, and quality control.

- If your primary focus is equipment longevity: Prioritize the use of high-purity water and conduct regular checks of the chiller and pumps to prevent scale buildup and ensure consistent flow.

- If your primary focus is consistent product quality: Recognize that a stable cooling system provides the repeatable thermal environment essential for achieving uniform metallurgical properties in every batch.

- If your primary focus is operational uptime and safety: Rely on the digital flow monitoring system as a critical safety interlock and diagnostic tool to preempt failures before they cause damage.

Ultimately, viewing the cooling system as an integral part of the sintering process, rather than a background utility, is fundamental to achieving safe, reliable, and high-quality production.

Summary Table:

| Function | Key Benefit | Critical Component |

|---|---|---|

| Heat Removal | Prevents furnace damage and failure | Double-walled chamber and power feedthroughs |

| Process Control | Ensures consistent thermal conditions for repeatable results | Digital flow sensors and temperature monitors |

| Component Protection | Maintains safe temperatures for seals and O-rings | Pure water circulation loop |

| Safety and Reliability | Avoids scaling and blockages with pure water | External heat exchanger or chiller |

Optimize your sintering process with KINTEK's advanced high-temperature furnace solutions! Our internal circulation pure water cooling systems are designed to deliver precise thermal management, ensuring your furnace operates safely and efficiently. Leveraging exceptional R&D and in-house manufacturing, we offer a range of products including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's performance and reliability!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures