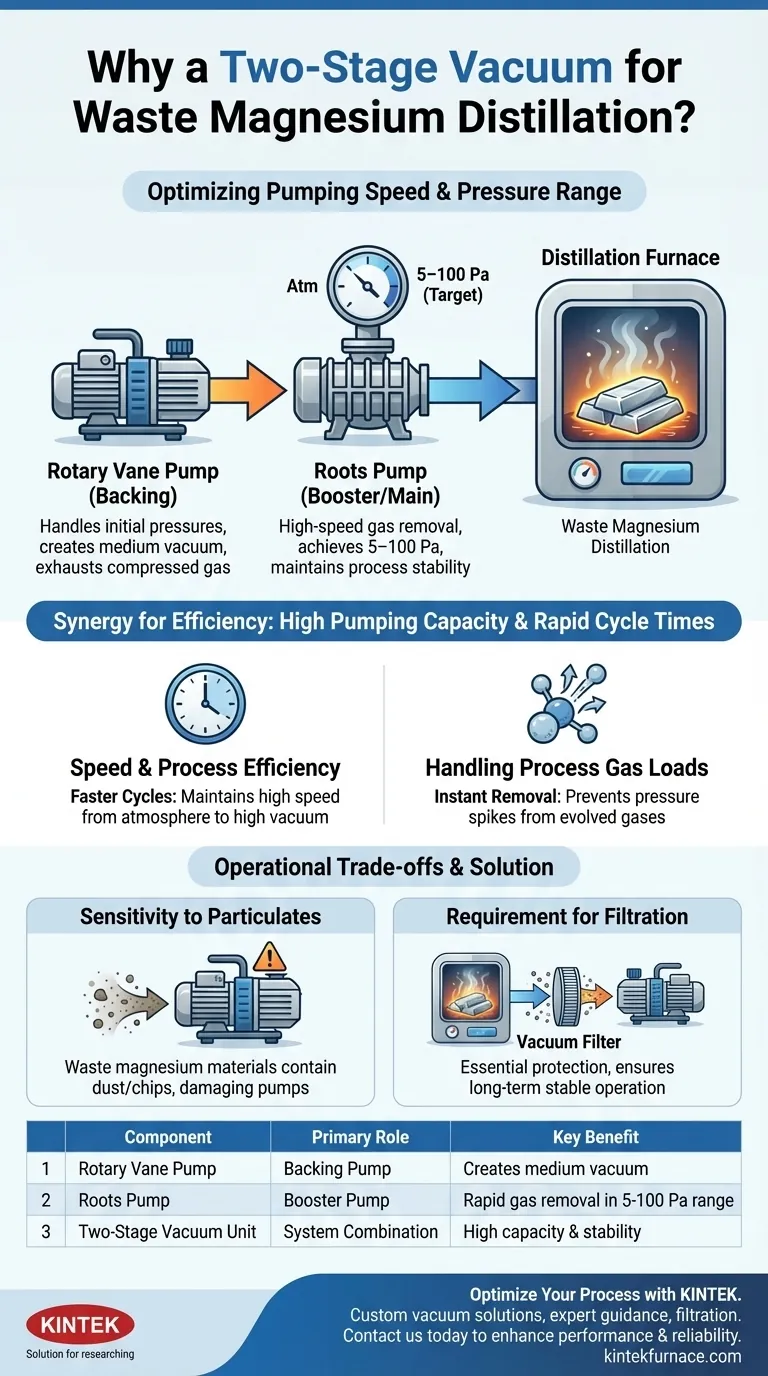

A two-stage vacuum unit is typically selected for waste magnesium distillation because it optimizes pumping speed across a wide pressure range, ensuring the system reaches the specific vacuum levels required for sublimation. The rotary vane pump acts as the "backing" unit to handle initial pressures, enabling the Roots pump to function as a high-speed booster that rapidly achieves and maintains the critical 5–100 Pa operating window.

The efficiency of magnesium distillation depends on lowering the boiling point via high vacuum. By combining a rotary vane pump for roughing and a Roots pump for boosting, operators achieve a high pumping capacity that neither pump could sustain individually, ensuring rapid gas removal and process stability.

The Mechanics of the Two-Stage System

The Role of the Rotary Vane Pump

The rotary vane pump serves as the backing pump (or fore-pump) in this configuration. Its primary function is preliminary pumping.

Because a Roots pump cannot discharge gas directly against atmospheric pressure, the rotary vane pump creates the necessary "medium vacuum" environment. It exhausts the gas compressed by the Roots pump, preventing backflow and system stall.

The Role of the Roots Pump

Once the rotary vane pump establishes a preliminary vacuum, the Roots pump acts as the main pump.

It functions as a mechanical booster, designed to move large volumes of gas rapidly at lower pressures. Its operation is critical for bridging the gap between medium vacuum and the high vacuum required for the distillation process.

Achieving the Target Pressure Range

Magnesium distillation specifically requires a low-pressure state, typically between 5 and 100 Pa.

This combination allows the system to reach this specific range quickly. While the rotary vane pump creates the initial pressure drop, the Roots pump takes over to fine-tune and hold the deep vacuum necessary for efficient magnesium vaporization.

Why This Matters for Magnesium Distillation

Speed and Process Efficiency

Time is a critical factor in industrial distillation. A single pump would struggle to maintain high pumping speeds across the entire pressure curve from atmosphere to high vacuum.

The two-stage unit ensures strong pumping capacity throughout the entire process. This results in rapid gas removal, allowing the furnace to reach operational conditions faster and shortening the overall distillation cycle.

Handling Process Gas Loads

Vacuum distillation of waste releases gases that must be evacuated immediately to prevent pressure spikes.

The high throughput of the Roots pump at low pressures ensures that evolved gases are removed instantly. This maintains the thermodynamic conditions required for magnesium to separate effectively from impurities.

Understanding the Operational Trade-offs

Sensitivity to Particulates

While this pump combination offers superior vacuum performance, it is mechanically precise and sensitive to contamination.

Waste magnesium raw materials often contain dust and fine magnesium chips. These particulates can easily damage the tight tolerances of a Roots pump or contaminate the oil in a rotary vane pump.

The Requirement for Filtration

To offset the risk of damage, this system requires a vacuum filter installed between the furnace and the pump group.

You cannot rely on the pumps alone to handle the environment. The filter acts as a core protective device, intercepting solid particles to prevent wear and ensure the long-term stable operation of the precision pump unit. Omitting this stage inevitably leads to equipment failure.

Making the Right Choice for Your Goal

When designing or operating a waste magnesium vacuum system, the pump configuration dictates your throughput and maintenance cycles.

- If your primary focus is process speed: Prioritize a Roots pump with a high displacement capacity to maximize gas removal rates in the 5–100 Pa range.

- If your primary focus is equipment longevity: Ensure the rotary vane backing pump is properly sized to prevent the Roots pump from overheating, and inspect upstream filters strictly to block magnesium dust.

The synergy between the rotary vane's compression capability and the Roots pump's speed provides the most reliable foundation for high-yield magnesium recovery.

Summary Table:

| Component | Primary Role | Key Benefit |

|---|---|---|

| Rotary Vane Pump | Backing Pump (Handles initial pressures) | Creates medium vacuum environment for Roots pump operation |

| Roots Pump | Booster Pump (Main pump for high vacuum) | Rapid gas removal in 5-100 Pa range for efficient distillation |

| System Combination | Two-Stage Vacuum Unit | High pumping capacity across wide pressure range, ensuring process stability |

Optimize Your Magnesium Distillation Process with KINTEK

Struggling with slow cycle times or unstable vacuum levels in your waste magnesium recovery system? The right vacuum solution is critical for achieving high yields and operational efficiency.

At KINTEK, we specialize in designing and manufacturing robust vacuum systems tailored for demanding industrial processes like magnesium distillation. Our expertise ensures your system operates reliably at the precise 5-100 Pa pressure window required for maximum efficiency.

We provide:

- Custom-configured vacuum systems integrating Roots and rotary vane pumps

- Expert guidance on system design to balance speed and equipment longevity

- High-quality filtration solutions to protect your investment from particulate contamination

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Contact us today to discuss how we can enhance your vacuum distillation performance and reliability. Let's build a solution that maximizes your recovery rates.

Get a Custom Solution for Your Lab

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules