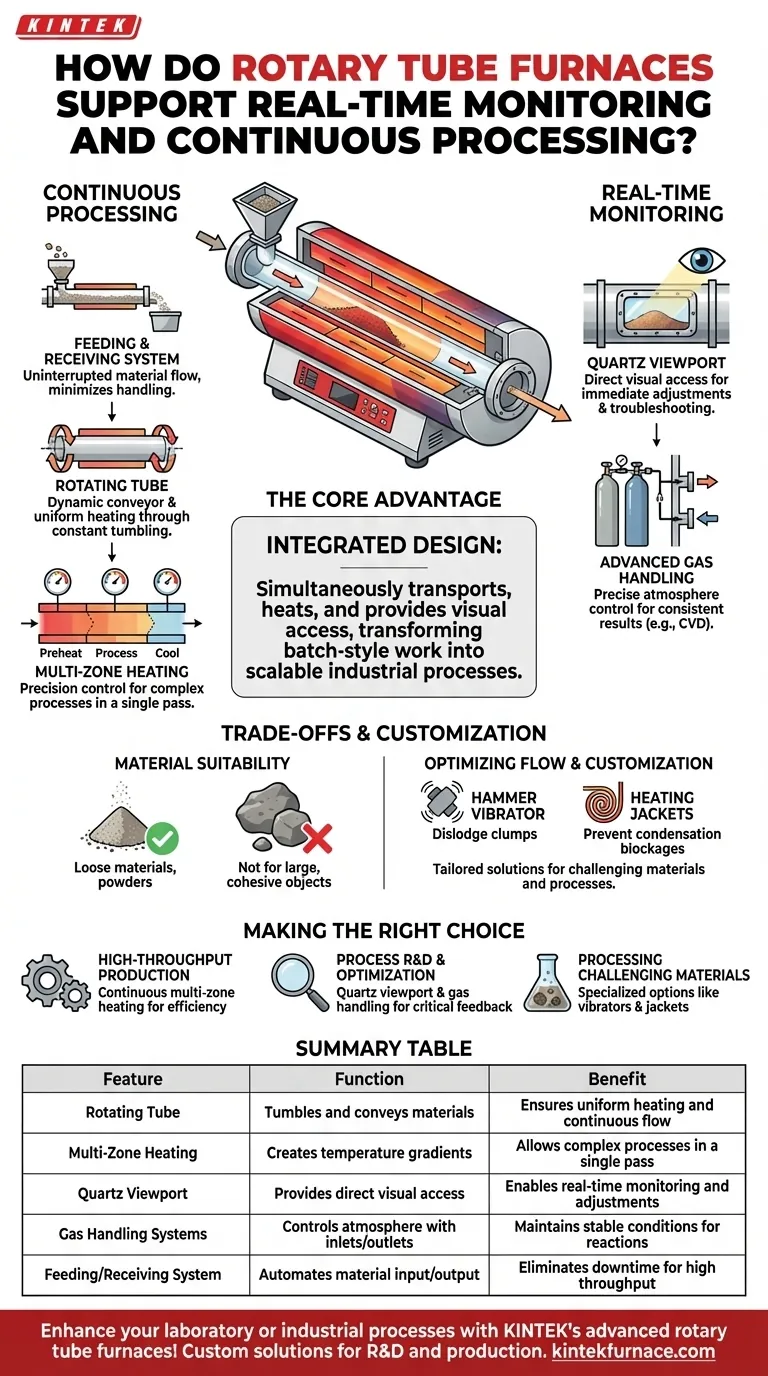

At their core, rotary tube furnaces enable real-time monitoring and continuous processing through two distinct design principles. A built-in quartz window provides a direct viewport for observing materials, while the fundamental mechanism of a rotating tube, combined with a dedicated feeding and receiving system, allows for the uninterrupted, uniform flow of materials from one end to the other.

The true advantage of a rotary tube furnace lies in its integrated design. The system's ability to simultaneously transport, heat, and provide visual access to materials transforms batch-style lab work into a continuous, controllable, and scalable industrial process.

The Mechanics of Continuous Processing

The furnace's suitability for continuous operation is not an add-on feature; it is fundamental to its design. Several integrated systems work together to ensure a steady, uninterrupted flow of material.

The Rotating Tube: A Dynamic Conveyor

The central element is the cylindrical work tube that rotates along its longitudinal axis. This constant, gentle tumbling action serves two purposes.

First, it ensures uniform heating by constantly exposing new surfaces of the material to the heat source. Second, it acts as a conveyor, methodically transporting loose materials like powders from the input end to the output end.

Multi-Zone Heating: Precision Over Distance

Many rotary furnaces are equipped with multiple thermal control zones. This allows for a precisely controlled temperature gradient along the length of the tube.

As material travels through the furnace, it can be subjected to a sequence of heating and cooling stages, enabling complex processes like calcining or specific chemical reactions to occur in a single, continuous pass.

Input and Output: The Key to Uninterrupted Flow

A dedicated feeding and receiving system is crucial for continuous operation. This allows raw material to be steadily introduced at one end and the processed material to be collected at the other without stopping the furnace.

This design minimizes material handling requirements and dramatically increases productivity by eliminating the downtime associated with loading and unloading traditional batch furnaces.

Enabling Real-Time Process Control

Beyond simple throughput, effective process control requires the ability to monitor and adjust conditions in real time. Rotary tube furnaces incorporate features specifically for this purpose.

The Quartz Viewport: A Direct Line of Sight

An integrated quartz window provides a clear viewport directly into the processing chamber. This is invaluable for processes like Chemical Vapor Deposition (CVD), where visual confirmation of material deposition and behavior is critical.

This direct observation allows operators to make immediate adjustments, troubleshoot issues, and ensure the process is running as intended without interrupting operations.

Advanced Gas Handling: Controlling the Atmosphere

Continuous processing, especially for CVD, requires a stable and controlled atmosphere. Rotary furnaces feature specialized gas ports, such as 1/4 inch inert gas inlets and KF25 outgassing ports.

These allow for the constant supply of inert or reactive gases and the efficient removal of byproducts. This maintains the precise atmospheric conditions necessary for consistent results over long production runs.

Understanding the Trade-offs and Customizations

While powerful, rotary tube furnaces are specialized tools. Understanding their limitations and options is key to successful implementation.

Material Suitability: Not a Universal Solution

These furnaces are explicitly designed for the continuous throughput of loose materials. They excel at processing powders, granules, and other free-flowing substances. They are not suitable for large, solid objects or materials that are highly cohesive.

Optimizing Flow for Difficult Materials

For materials that are prone to clumping or sticking, such as high-viscosity organic compounds, standard rotation may not be enough.

Optional features like a hammer vibrator can be added to dislodge clumps and maintain flow. For processes that create condensable byproducts like tar, heating jackets can be installed on connections to prevent blockages.

Design Customization: Tailoring to the Process

The versatility of a rotary tube furnace comes from its potential for customization. The size, shape, and material of the work tube, as well as the heating elements and control systems, can often be tailored to the specific demands of an application.

Making the Right Choice for Your Process

Selecting the right thermal processing equipment depends entirely on your primary objective.

- If your primary focus is high-throughput industrial production: The furnace's ability to run continuously with multi-zone heating offers unmatched efficiency and scalability for processes like calcining and roasting.

- If your primary focus is process R&D and optimization: The quartz viewport and precise gas handling provide the critical feedback needed to observe, refine, and perfect sensitive processes like CVD.

- If your primary focus is processing challenging materials: Inquire about specialized options like hammer vibrators or heating jackets to ensure your specific material can flow without interruption.

Ultimately, a rotary tube furnace is the definitive choice when your process demands both continuous material flow and precise, observable control.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Rotating Tube | Tumbles and conveys materials | Ensures uniform heating and continuous flow |

| Multi-Zone Heating | Creates temperature gradients | Allows complex processes in a single pass |

| Quartz Viewport | Provides direct visual access | Enables real-time monitoring and adjustments |

| Gas Handling Systems | Controls atmosphere with inlets/outlets | Maintains stable conditions for reactions |

| Feeding/Receiving System | Automates material input/output | Eliminates downtime for high throughput |

Enhance your laboratory or industrial processes with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental needs, whether for high-throughput production, R&D optimization, or handling challenging materials. Contact us today to discuss how our high-temperature furnace solutions can boost your efficiency and scalability!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing