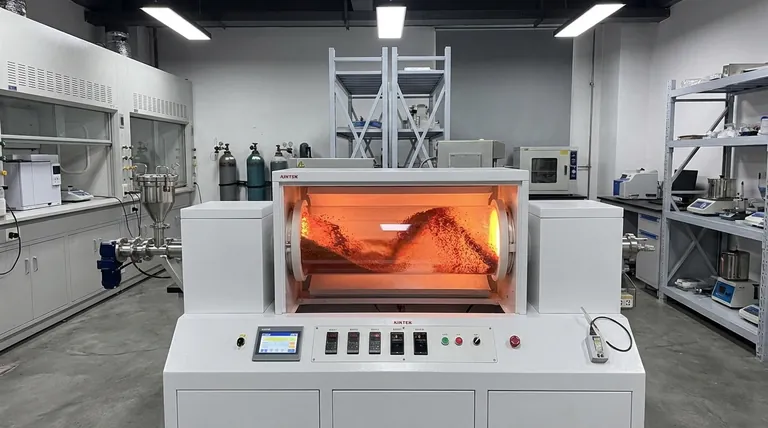

At its core, a rotary tube furnace is indispensable for thermally processing powders and granular materials. Its most common applications include powder metallurgy, advanced material synthesis, and chemical reactions like calcination, where uniform heating and constant agitation are critical. This design is specifically engineered for processes that cannot tolerate temperature gradients or material segregation.

The defining feature of a rotary tube furnace is its ability to simultaneously heat and mix materials. This continuous agitation is not a secondary benefit—it is the core reason this furnace is chosen over static alternatives for processes requiring exceptional thermal and chemical uniformity.

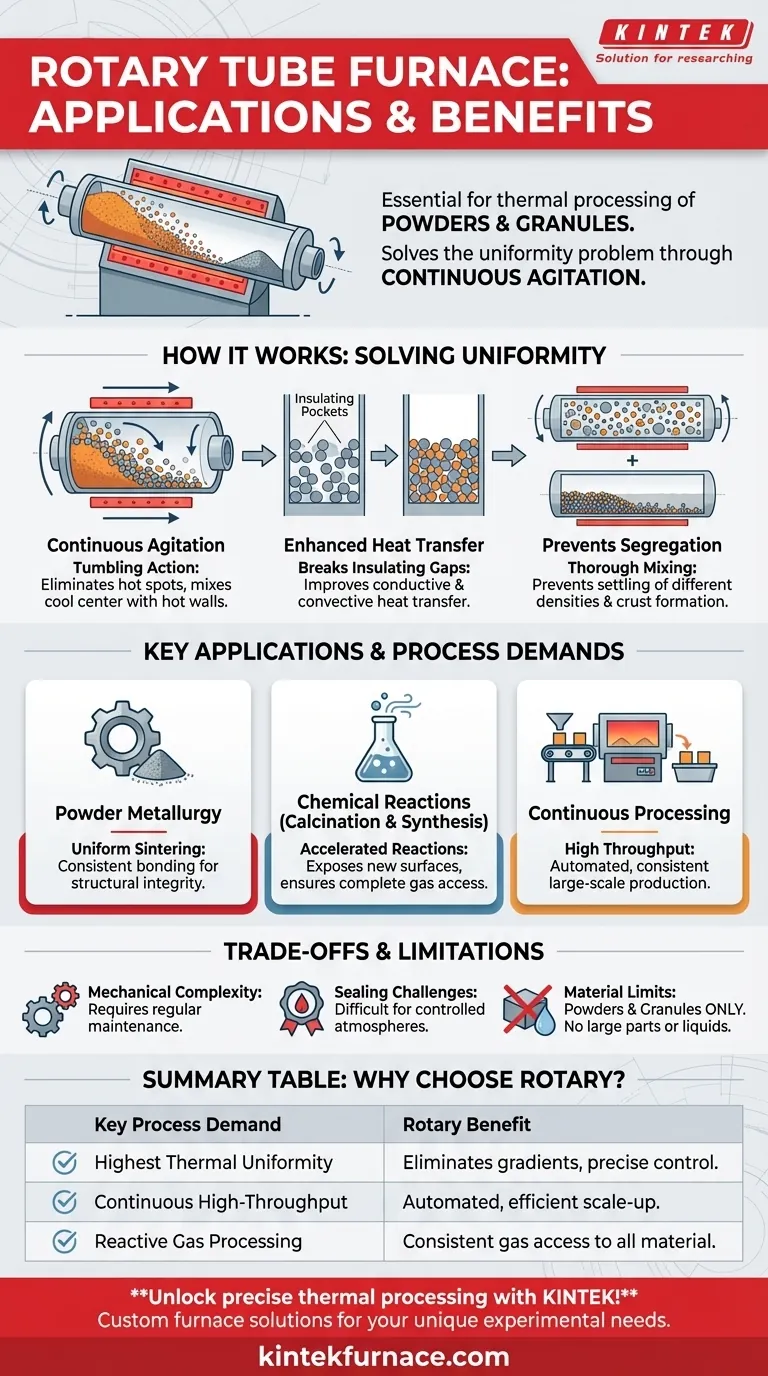

How a Rotary Tube Furnace Solves the Uniformity Problem

A static furnace, whether a box or a standard tube furnace, heats material from the outside in. This inherently creates temperature gradients, where the material touching the walls is hotter than the material in the center. A rotary tube furnace is designed specifically to overcome this fundamental limitation.

The Principle of Continuous Agitation

The furnace tube rotates slowly and is often tilted at a slight angle. This action continuously tumbles the powder or granular sample inside.

As the material cascades, particles from the cooler center are constantly brought to the hotter outer wall, and vice versa. This forced mixing eliminates hot spots and ensures every particle experiences a nearly identical temperature profile over time.

Enhancing Heat Transfer Efficiency

In a static powder bed, air gaps between particles act as an insulator, slowing down heat transfer. The tumbling motion in a rotary furnace breaks up these insulating pockets.

This significantly enhances conductive and convective heat transfer throughout the material bed, leading to faster processing times and more predictable, repeatable results.

Preventing Material Settling and Inconsistency

For processes involving mixtures of materials with different densities, a static furnace allows heavier particles to settle. This segregation can ruin the final product.

The rotary action ensures the materials remain thoroughly mixed. It also prevents the formation of a sintered crust on the surface, which would otherwise insulate the material beneath it and prevent reactive gases from penetrating the sample.

Key Applications and Their Process Demands

The unique capabilities of a rotary tube furnace make it the ideal choice for specific, demanding industrial and research applications.

Powder Metallurgy

In powder metallurgy, metal powders are heated below their melting point (sintering) to bond them into a solid part. Uniform heating is non-negotiable.

Uneven temperatures would lead to inconsistent bonding, creating weak spots and compromising the structural integrity of the final component. The rotary action ensures every particle is sintered under the same conditions.

Chemical Reactions (Calcination & Synthesis)

Processes like calcination involve heating a material to drive off volatiles or induce a phase transition. The continuous mixing exposes new surfaces, accelerating the reaction and ensuring it proceeds to completion uniformly.

When synthesizing new materials in a controlled atmosphere, the rotary motion ensures that reactive gases have consistent access to the entire sample, rather than just the surface layer.

Continuous Processing

When equipped with automated feeders and collection systems, a rotary tube furnace can operate continuously. Raw material is fed into the high end of the tilted tube and slowly travels to the low end as it rotates, emerging as a fully processed product.

This makes it highly efficient for large-scale production where consistent throughput and quality are essential.

Understanding the Trade-offs

While powerful, the rotary design introduces complexities that make it unsuitable for certain applications. Objectivity requires acknowledging its limitations.

Mechanical Complexity

The addition of a motor, drive system, and rotating seals creates more potential points of failure than a simple static furnace. These systems require regular inspection and maintenance.

Sealing for Controlled Atmospheres

Maintaining a perfect, gas-tight seal on a rotating tube is significantly more challenging than on a static one. While high-quality seals are available, they add to the cost and are a critical maintenance component for atmosphere-controlled processes.

Material and Sample Limitations

This furnace is designed exclusively for powders, granules, or small, free-flowing solids. It cannot be used for processing large monolithic parts, delicate structures that would be destroyed by tumbling, or most liquid samples.

Making the Right Choice for Your Process

Your decision must be guided by the physical nature of your sample and the required uniformity of the process.

- If your primary focus is processing powders or granules that demand the highest thermal uniformity: A rotary tube furnace is the optimal solution, far exceeding the capabilities of a static furnace.

- If your primary focus is high-throughput continuous production: The inherent design of a tilted rotary furnace is built for automated, continuous workflows, making it a superior choice for industrial scale.

- If your primary focus is treating solid parts, delicate samples, or operating on a limited budget: A standard static tube or box furnace is a more practical, reliable, and cost-effective choice.

Ultimately, understanding this core principle of dynamic heating is the key to selecting the right thermal processing equipment for your specific goal.

Summary Table:

| Application | Key Process Demands | Benefits of Rotary Tube Furnace |

|---|---|---|

| Powder Metallurgy | Uniform heating, consistent bonding | Eliminates temperature gradients, ensures even sintering |

| Chemical Reactions (e.g., Calcination) | Accelerated reactions, gas access | Continuous mixing exposes surfaces, enhances uniformity |

| Continuous Processing | High throughput, automated workflows | Efficient material flow, consistent product quality |

Unlock precise thermal processing for your lab with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for powders, granules, and continuous processes. Contact us today to enhance your efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing