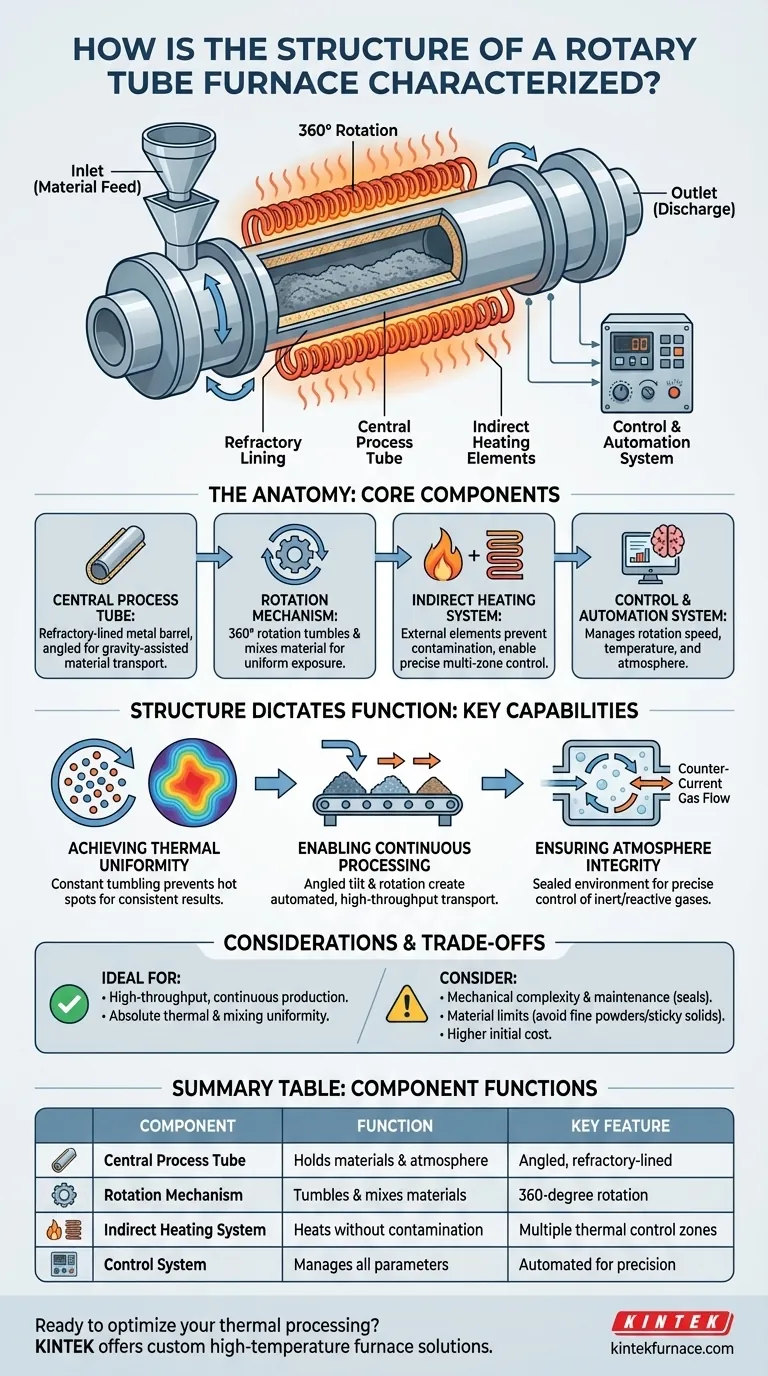

At its core, a rotary tube furnace is defined by its central, rotating process tube, which is lined with refractory material and mounted at a slight angle. This unique architecture is not arbitrary; it is engineered specifically to transport material continuously from one end to the other while tumbling it, ensuring exceptionally uniform heat treatment and mixing under a controlled atmosphere.

The defining structure of a rotary tube furnace—an angled, rotating, and indirectly heated tube—is a direct solution for achieving exceptional thermal uniformity and continuous material processing under precisely controlled atmospheric conditions.

The Anatomy of a Rotary Tube Furnace

To understand its function, we must first break down its fundamental structural components. Each part plays a critical role in the furnace's overall performance.

The Central Process Tube

This is the heart of the system. It is typically a metal barrel or drum that contains the process materials and atmosphere.

The inside is lined with a refractory material designed to withstand extreme temperatures and protect the outer metal structure.

Crucially, the entire tube assembly is installed at a slight angle. This tilt uses gravity to help move the material through the furnace as it rotates.

The Rotation Mechanism

The furnace is engineered to rotate 360 degrees around its central axis.

This rotation serves two primary purposes: it continuously tumbles the material to ensure every particle is exposed to the same heat, and it induces mixing or stirring, which is vital for many chemical reactions.

The Indirect Heating System

Rotary tube furnaces utilize an indirect-fired design. The heating elements are located outside the process tube.

This separation prevents contamination of the sample by the heating elements and allows for highly precise temperature control.

Advanced systems feature multiple thermal control zones along the length of the tube, allowing for a tailored temperature profile as the material travels through the furnace.

The Control and Automation System

The physical furnace structure is governed by an electric control section.

This system manages all critical parameters, including the tube's rotation speed, the temperature in each heating zone, and the composition of the process atmosphere. Modern controls allow for a high degree of automation and remote monitoring.

How Structure Dictates Function

The unique architecture of a rotary tube furnace directly enables its most valuable capabilities. The design is a solution to common challenges in thermal processing.

Achieving Thermal Uniformity

The constant rotation is the key to preventing hot spots. By tumbling the material, the furnace ensures that heat is distributed evenly throughout the sample batch, leading to highly consistent and repeatable results.

Enabling Continuous Processing

Unlike a static batch furnace, the combination of the slight tilt and controlled rotation creates an automated material transport system.

Material is fed into the higher end (inlet) and slowly travels to the lower end (outlet), making the furnace ideal for continuous, high-throughput production environments.

Ensuring Atmosphere Integrity

The enclosed tube creates a sealed environment. This allows for precise control over the internal atmosphere.

Gases—whether inert, oxidizing, or reducing—can be introduced to facilitate specific chemical processes like calcination or pyrolysis. Often, the gas flows in the opposite direction of the material (counter-current flow) to maximize reaction efficiency.

Understanding the Trade-offs

No technology is a universal solution. The specialized structure of a rotary tube furnace comes with specific considerations.

Complexity and Maintenance

The inclusion of a rotating mechanism introduces moving parts. The seals at the inlet and outlet are critical for maintaining atmosphere integrity and are subject to wear, requiring regular inspection and maintenance.

Material Suitability

This design is ideal for granular, crystalline, or free-flowing powders and small parts. Extremely fine powders may become entrained in the process gas stream, while sticky or agglomerating materials can build up on the tube walls, hindering performance.

Scalability and Cost

While highly efficient for continuous processing, rotary tube furnaces can represent a higher initial capital investment compared to simpler, static batch furnaces. Their mechanical complexity can also influence operational costs over the long term.

Making the Right Choice for Your Process

Your specific goal will determine if this furnace's structure is the correct fit for your application.

- If your primary focus is high-throughput, continuous production: The automated material transport enabled by the angled, rotating tube is a decisive advantage.

- If your primary focus is absolute sample uniformity: The constant tumbling action provides superior thermal consistency and mixing compared to any static furnace design.

- If your primary focus is processing small, static batches on a limited budget: A simpler, non-rotating batch tube or muffle furnace may be a more cost-effective solution.

Understanding this architecture empowers you to match the right thermal processing technology to your specific material and production goals.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Central Process Tube | Holds materials and atmosphere | Angled, refractory-lined for heat resistance |

| Rotation Mechanism | Tumbles and mixes materials | 360-degree rotation for uniform exposure |

| Indirect Heating System | Heats without contamination | Multiple thermal control zones |

| Control System | Manages rotation, temperature, atmosphere | Automated for precision and monitoring |

Ready to optimize your thermal processing with a custom rotary tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior uniformity and efficiency. Contact us today to discuss how we can enhance your lab's performance!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency