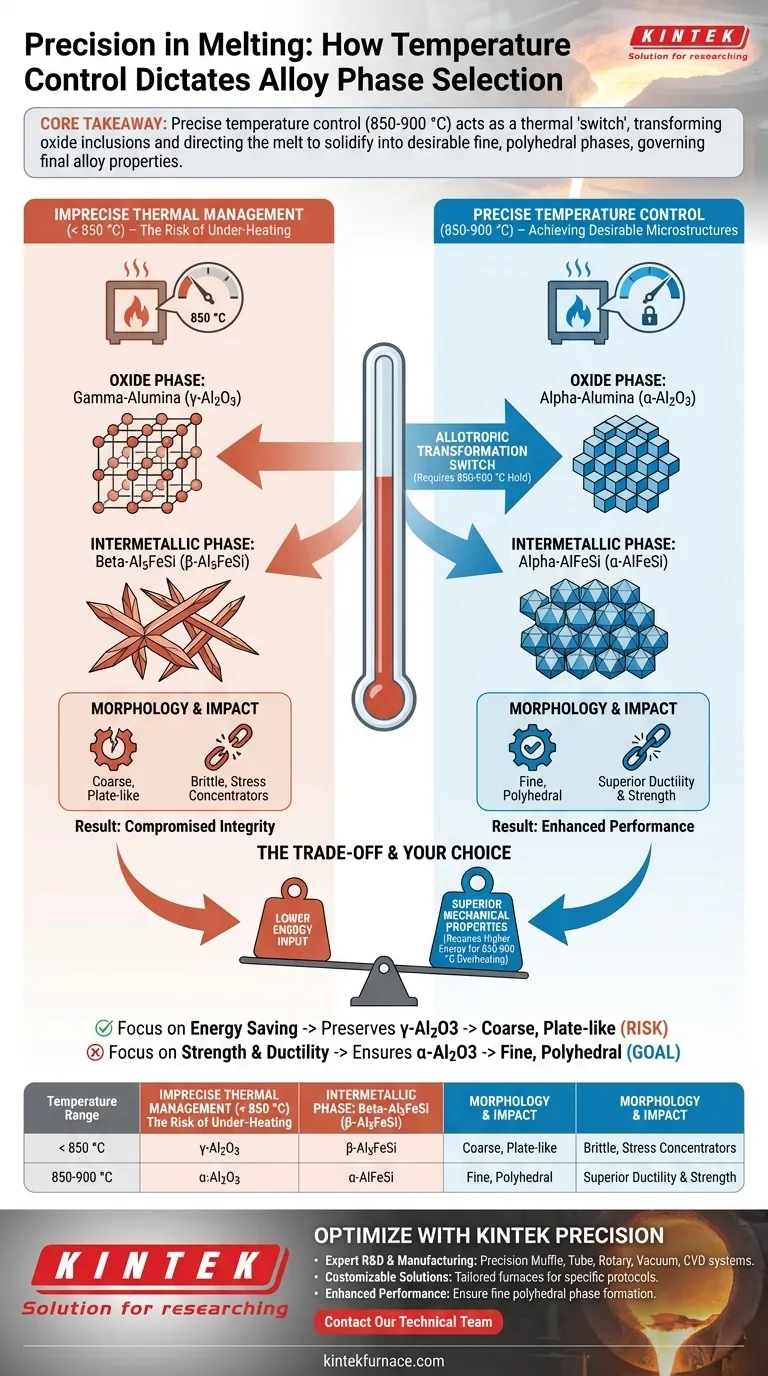

Precise temperature control governs the physical properties of the final alloy by triggering specific allotropic transformations within the melt's oxide inclusions. Specifically, heating the melt to the 850-900 °C range converts the crystal structure of oxide surfaces, which subsequently forces the solidification process to favor fine, polyhedral phases over coarse, plate-like structures.

Core Takeaway The accuracy of thermal management dictates the thermodynamic stability of oxide films suspended in the melt. By ensuring the correct temperature window is reached, you effectively "switch" the nucleation substrate, directing the melt to precipitate desirable fine intermetallic compounds rather than detrimental coarse ones.

The Mechanism of Phase Transformation

Inducing Allotropic Changes

In many industrial melts, oxide phases exist naturally. At lower melt temperatures, these often persist as gamma-alumina ($\gamma$-Al2O3).

However, precise overheating to the 850-900 °C range provides the necessary thermal energy to induce an allotropic transformation.

This process converts the gamma-alumina into alpha-alumina ($\alpha$-Al2O3). This is not merely a temperature change; it is a fundamental restructuring of the oxide's crystal lattice.

Directing the Solidification Path

The crystal structure of the oxide acts as a template for the intermetallic compounds that form as the metal cools.

If the melt retains $\gamma$-Al2O3 (due to insufficient heating), it triggers the precipitation of $\beta$-Al5FeSi.

This phase is characterized by a coarse, plate-like morphology, which is generally undesirable for mechanical properties as it acts as a stress concentrator.

Achieving Desirable Microstructures

Conversely, when the oxide successfully transforms into $\alpha$-Al2O3 through precise heating, the nucleation path shifts.

This oxide structure favors the formation of $\alpha$-AlFeSi phases.

These phases are fine and polyhedral (compact and multi-faceted). This morphology is far superior for the structural integrity and ductility of the final casting.

Understanding the Trade-offs

The Risk of Under-Heating

If the furnace fails to maintain the strict 850-900 °C window, the allotropic transformation of the oxide surface will not occur.

The melt effectively retains a "memory" of the lower-temperature oxide structure ($\gamma$-Al2O3).

Consequently, regardless of cooling rates later in the process, the material is predisposed to form brittle, coarse plate-like phases.

Energy vs. Quality

Achieving this transformation requires higher energy input to reach the overheating zone.

Operators must balance the energy cost of high-temperature overheating against the critical need for superior mechanical properties delivered by fine polyhedral phases.

Making the Right Choice for Your Goal

To optimize your casting results, align your temperature control strategy with your material performance requirements:

- If your primary focus is mechanical strength and ductility: Ensure your furnace creates a stable hold at 850-900 °C to guarantee the full conversion to $\alpha$-Al2O3 and the subsequent formation of fine polyhedral phases.

- If your primary focus is minimizing energy consumption: Be aware that operating below this threshold preserves $\gamma$-Al2O3, which will inevitably result in coarse, plate-like microstructures that may compromise part durability.

Precision in the liquid state dictates the performance of the solid state.

Summary Table:

| Temperature Range | Oxide Phase | Intermetallic Phase | Morphology | Mechanical Impact |

|---|---|---|---|---|

| < 850 °C | $\gamma$-Al2O3 | $\beta$-Al5FeSi | Coarse, Plate-like | Brittle, Stress Concentrators |

| 850 - 900 °C | $\alpha$-Al2O3 | $\alpha$-AlFeSi | Fine, Polyhedral | Superior Ductility & Strength |

Optimize Your Alloy Microstructure with KINTEK Precision

Don't let imprecise thermal management compromise your material integrity. At KINTEK, we understand that the transition from $\gamma$ to $\alpha$ oxide phases requires rigorous temperature accuracy. Our industrial heating solutions are engineered to deliver the exact thermal windows needed for advanced phase selection.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Precision-engineered Muffle, Tube, Rotary, Vacuum, and CVD systems.

- Customizable Solutions: Tailored high-temp furnaces to meet your specific metallurgical overheating protocols.

- Enhanced Material Performance: Ensure the formation of fine polyhedral phases for superior ductility and strength.

Ready to elevate your casting quality? Contact our technical team today to discuss your custom furnace requirements.

Visual Guide

References

- Gábor Gyarmati, Ján Erdélyi. Intermetallic Phase Control in Cast Aluminum Alloys by Utilizing Heterogeneous Nucleation on Oxides. DOI: 10.3390/met15040404

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of vacuum hardening? Achieve Superior Surface Quality and Dimensional Accuracy

- What are the benefits of using graphite felt in vacuum furnaces? Achieve Superior Thermal Efficiency & Stability

- What is sintering in a vacuum atmosphere? Achieve Maximum Purity for High-Performance Parts

- What is 'hydrogen disease' in copper heat treatment and how does vacuum annealing prevent it? Learn to Avoid Catastrophic Failure

- What are the primary benefits of vacuum heat treatment technology? Achieve Superior Metallurgical Control and Quality

- Why is an industrial high vacuum sintering furnace required for high-porosity Hastelloy-X? Ensure Alloy Integrity

- How does vacuum sintering improve surface finish? Achieve Superior, Oxide-Free Results

- What are the challenges of relying solely on a vacuum in furnace applications? Overcome Key Operational Hurdles