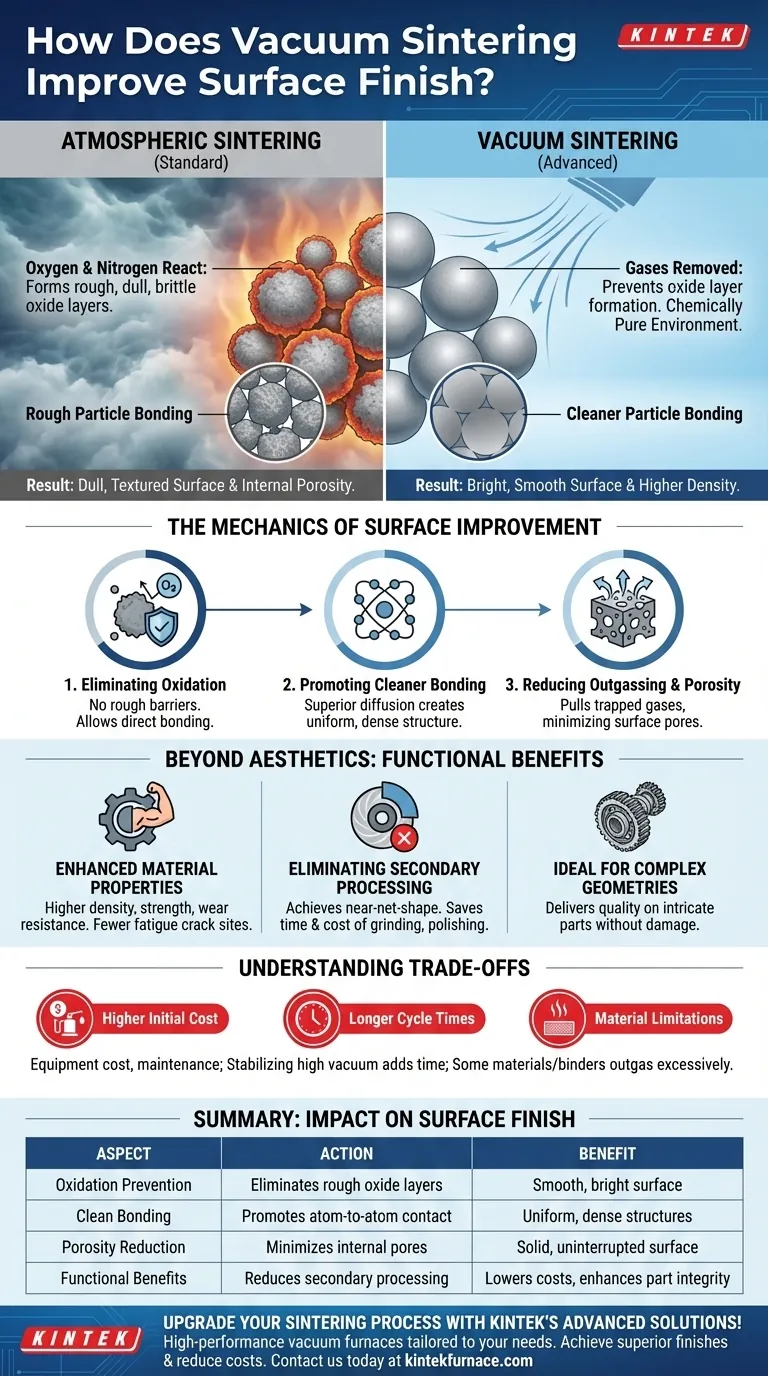

At its core, vacuum sintering improves surface finish by creating a chemically pure environment. By removing atmospheric gases like oxygen before the heating process begins, it prevents the formation of rough, dull oxide layers on the individual powder particles. This allows the particles to bond directly and cleanly, resulting in a sintered part with a significantly brighter and smoother surface.

The true value of the improved surface from vacuum sintering is not just aesthetic. By eliminating oxidation, the process yields parts with higher integrity that often require fewer secondary finishing steps, directly reducing overall production time and cost.

The Mechanics of Surface Improvement

To understand the benefits, we must first look at what happens at the microscopic level during the sintering process. The goal is to fuse metal powder into a solid mass just below its melting point.

Preventing Oxidation at the Particle Level

In a standard atmospheric furnace, the high temperatures cause oxygen and nitrogen to react aggressively with the metal powder's surface. This reaction creates a brittle, non-metallic oxide or nitride layer on each particle.

These oxide layers are rough and inhibit clean metallic bonding, leading to a dull, textured final surface.

Promoting Cleaner Particle Bonding

The vacuum environment removes the reactive gases. Without an oxide barrier, the metal particles make direct, atom-to-atom contact as they are heated.

This clean contact facilitates superior diffusion and bonding between particles, creating a more uniform, dense, and metallurgically sound surface structure, which we perceive as smooth and bright.

Reducing Outgassing and Porosity

A secondary benefit of the vacuum is its ability to pull trapped gases out of the compacted powder. This process, known as outgassing, helps minimize internal porosity near the part's surface.

Fewer pores result in a more solid and less interrupted surface, further contributing to smoothness and overall part density.

Beyond Aesthetics: The Functional Benefits

A superior surface finish is often a visible indicator of enhanced underlying material properties and a more efficient manufacturing workflow.

Enhanced Material Properties

The clean, oxide-free bonding achieved in a vacuum is not limited to the surface. It happens throughout the part, leading to higher overall density, strength, and wear resistance.

A smoother surface also has fewer microscopic notches or initiation sites for fatigue cracks, improving the component's operational lifespan under stress.

Eliminating Secondary Processing

Many parts made via conventional sintering require secondary steps like grinding, polishing, or sandblasting to achieve the desired surface finish. These steps add time, cost, and complexity.

Vacuum sintering can produce a near-net-shape part with a finish that is often acceptable without any further processing, representing a significant cost saving.

Ideal for Complex Geometries

For small or intricately shaped parts, performing secondary finishing operations can be difficult or even impossible without damaging the component.

Vacuum sintering provides a critical advantage here, as it delivers the required surface quality directly out of the furnace, ensuring the integrity of complex designs.

Understanding the Trade-offs

No process is without its compromises. Objectivity requires acknowledging the challenges associated with vacuum sintering.

Higher Initial Equipment Cost

Vacuum furnaces are more complex and expensive to purchase, install, and maintain than their atmospheric counterparts. The need for robust vacuum pumps, seals, and control systems adds to the initial capital investment.

Potentially Longer Cycle Times

Achieving and stabilizing a high vacuum adds time to the beginning of every cycle. While the sintering itself may be efficient, the overall floor-to-floor time can sometimes be longer than for a continuous atmospheric process.

Material Limitations

Certain materials or the binders mixed with them can have high vapor pressures. In a vacuum, these elements can "outgas" excessively or even vaporize from the part, potentially altering the material's final composition or contaminating the furnace interior.

Making the Right Choice for Your Application

Selecting the correct sintering process depends entirely on your project's technical requirements and financial constraints.

- If your primary focus is achieving the highest possible material purity and performance: Vacuum sintering is the superior choice, as it eliminates atmospheric contamination that compromises strength and fatigue life.

- If your primary focus is reducing post-processing costs on complex parts: The excellent as-sintered surface finish can deliver significant savings by minimizing or eliminating expensive secondary machining.

- If your primary focus is high-volume production of simple parts where surface finish is not critical: A continuous atmospheric furnace may offer a more cost-effective solution with faster throughput.

Ultimately, choosing vacuum sintering is an investment in final part quality, trading higher process control for a superior and more reliable component.

Summary Table:

| Aspect | Impact on Surface Finish |

|---|---|

| Oxidation Prevention | Eliminates rough oxide layers, allowing clean particle bonding for a smooth, bright surface. |

| Clean Bonding | Promotes atom-to-atom contact, leading to uniform, dense structures and improved surface integrity. |

| Porosity Reduction | Minimizes internal pores through outgassing, resulting in a more solid and uninterrupted surface. |

| Functional Benefits | Reduces need for secondary processing, lowers costs, and enhances part strength and lifespan. |

Upgrade your sintering process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance vacuum furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet unique experimental requirements. Achieve superior surface finishes, reduce production costs, and enhance part quality—contact us today to discuss how we can optimize your sintering operations!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures