At its core, a vacuum furnace is a specialized chamber used for the high-temperature processing of materials in an environment free from air and other gases. Its primary applications include advanced heat treatments like annealing and hardening, joining materials through brazing, and fusing powders into solids via sintering. These processes are critical for manufacturing high-performance components across various industries.

The fundamental purpose of a vacuum furnace isn't just to heat things up; it's to do so in a chemically pure environment. By removing oxygen and other reactive gases, it prevents contamination and allows materials to achieve properties that would be impossible in a conventional, air-filled furnace.

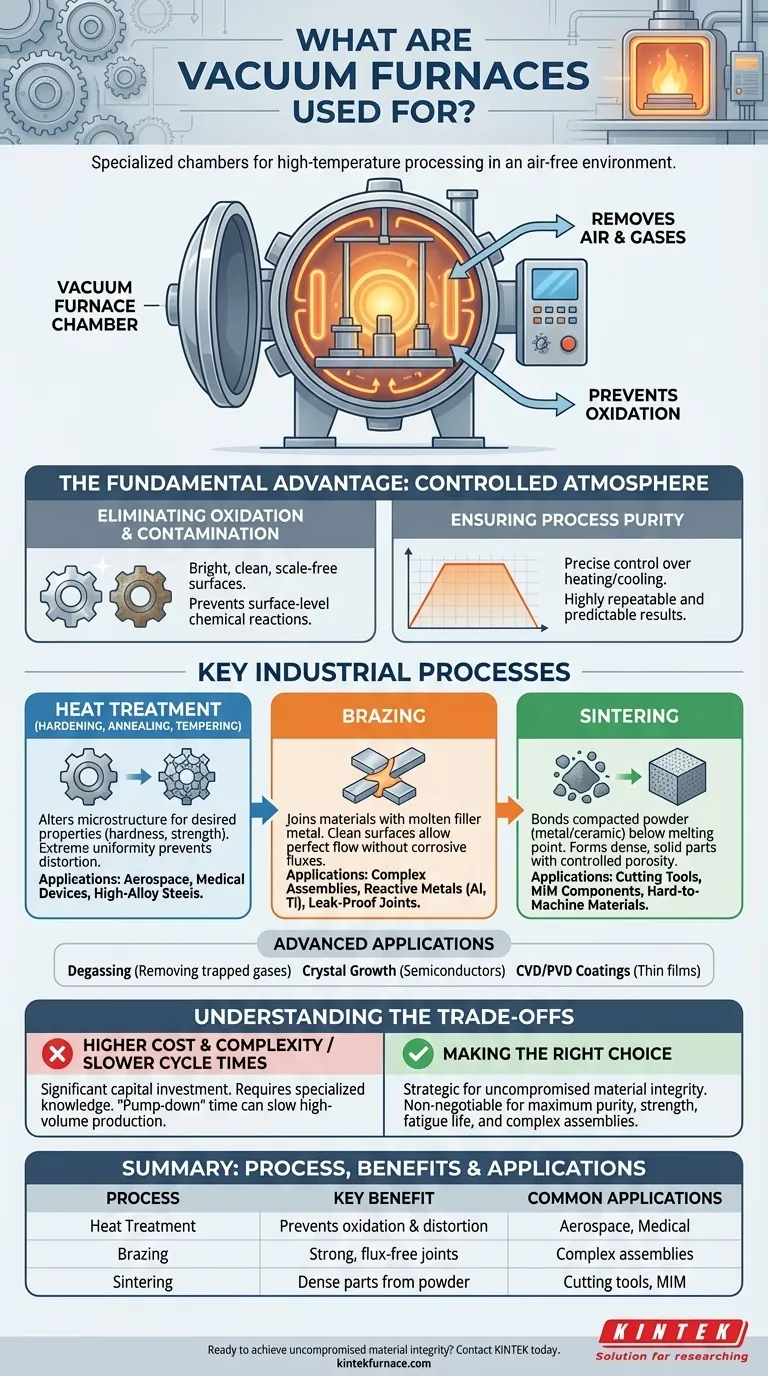

The Fundamental Advantage: A Controlled Atmosphere

At high temperatures, most materials become highly reactive. When exposed to air, they quickly oxidize, forming a weak, brittle layer on their surface. A vacuum furnace solves this problem by removing the atmosphere before the heating process begins.

Eliminating Oxidation and Contamination

The most critical function of a vacuum furnace is to prevent oxidation. This ensures the material's surface remains bright, clean, and free from the scale or discoloration that plagues parts heated in air.

This contamination-free environment is essential for achieving the precise, intended properties of the material without any unwanted surface-level chemical reactions.

Ensuring Process Purity

By operating in a vacuum, the furnace provides an extremely pure environment. This allows for precise control over the heating and cooling cycles, leading to highly repeatable and predictable results.

This level of control is vital for materials used in critical applications where even minor deviations in properties can lead to failure.

Key Industrial Processes

Vacuum technology enables several key manufacturing and treatment processes that demand absolute purity and control. Each process leverages the vacuum to achieve a specific outcome.

Heat Treatment (Hardening, Annealing, Tempering)

These processes alter a material's microstructure to achieve desired properties like hardness, strength, or ductility. In a vacuum, parts can be heated and cooled with extreme uniformity.

This prevents distortion and ensures that the entire part—not just the surface—achieves the target metallurgical structure. This is used extensively for high-alloy steels and specialized alloys.

Brazing

Brazing joins two or more metal items by melting a filler metal into the joint. Vacuum brazing is superior to other methods because the clean, oxide-free surfaces allow the filler metal to flow perfectly.

This creates an exceptionally strong, clean, and void-free joint without the need for corrosive fluxes, which are difficult to clean and can compromise the part's integrity.

Sintering

Sintering is the process of taking a compacted powder—often metal or ceramic—and heating it to just below its melting point. The vacuum allows the individual particles to bond directly at a molecular level.

This forms a dense, solid part with controlled porosity and excellent strength. It's essential for producing components from hard-to-machine materials like tungsten carbide or creating complex shapes through metal injection molding (MIM).

Advanced Applications

Beyond the core processes, vacuum furnaces are used for highly specialized tasks like degassing (removing trapped gases from a material), crystal growth for semiconductors, and applying ultra-thin CVD/PVD coatings.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every heating application. Their benefits come with specific considerations.

Higher Cost and Complexity

Vacuum furnaces and their associated pumping systems represent a significantly higher capital investment than standard atmospheric furnaces. They also require more specialized knowledge to operate and maintain.

Slower Cycle Times

The process of evacuating the chamber to the required vacuum level takes time. For high-volume production of simple parts, this "pump-down" time can make the overall cycle slower than continuous, open-air furnace operations.

When It's Overkill

For many routine heat treatments on common carbon steels where a small amount of surface oxidation is acceptable or can be easily removed later, a vacuum furnace is unnecessary. A simpler, more cost-effective atmospheric furnace is often the better choice.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace is driven entirely by the required final quality and performance of the component.

- If your primary focus is maximum material purity, strength, and fatigue life: A vacuum furnace is non-negotiable for demanding applications in aerospace, medical, and high-end electronics.

- If your primary focus is creating strong, clean, and leak-proof joints: Vacuum brazing provides superior results for complex assemblies, especially with reactive materials like aluminum or titanium.

- If your primary focus is creating dense parts from metal or ceramic powders: Vacuum sintering is the industry standard for achieving superior strength and material properties.

- If your primary focus is low-cost, high-volume heat treatment where surface finish is not critical: A conventional atmospheric furnace is almost always the more practical and economical solution.

Ultimately, choosing a vacuum furnace is a strategic decision to achieve uncompromised material integrity.

Summary Table:

| Process | Key Benefit | Common Applications |

|---|---|---|

| Heat Treatment (Annealing, Hardening) | Prevents oxidation and distortion | Aerospace components, medical devices |

| Brazing | Creates strong, flux-free joints | Complex assemblies in reactive metals |

| Sintering | Forms dense parts from metal/ceramic powders | Cutting tools, MIM components |

| Degassing / Coating | Removes trapped gases; applies thin films | Semiconductors, specialty alloys |

Ready to achieve uncompromised material integrity for your most demanding applications?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our vacuum furnaces are engineered for precision, ensuring the purity and performance required in aerospace, medical, and electronics manufacturing. Whether you need standard models or a fully customized system, our expertise in Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems ensures your unique requirements are met.

Contact us today to discuss how our vacuum furnace solutions can enhance your production quality and reliability.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What materials are processed in a high-pressure and high-flow rate gas quenching vacuum furnace? Ideal for High-Performance Alloys

- What role does a reduction furnace play in the activation of CuO-Fe3O4 catalysts? Master Catalyst Engineering

- Why is high vacuum control essential for CNT/Cu composites? Unlock Peak Conductivity and Purity

- How does a vacuum sintering furnace facilitate the final densification of 3D-printed fused silica glass? Expert Guide

- How can the heating speed and furnace temperature uniformity be improved in vacuum sintering? Boost Efficiency with Gas-Assisted Methods

- What are the characteristics of parts that undergo vacuum carburizing? Achieve Superior Dual-Property Performance

- What are the benefits of using drop-bottom quench furnaces? Achieve Superior Metallurgical Precision and Rapid Quenching

- What are the benefits of heating metals in a vacuum furnace? Achieve Pristine Surfaces and Superior Strength