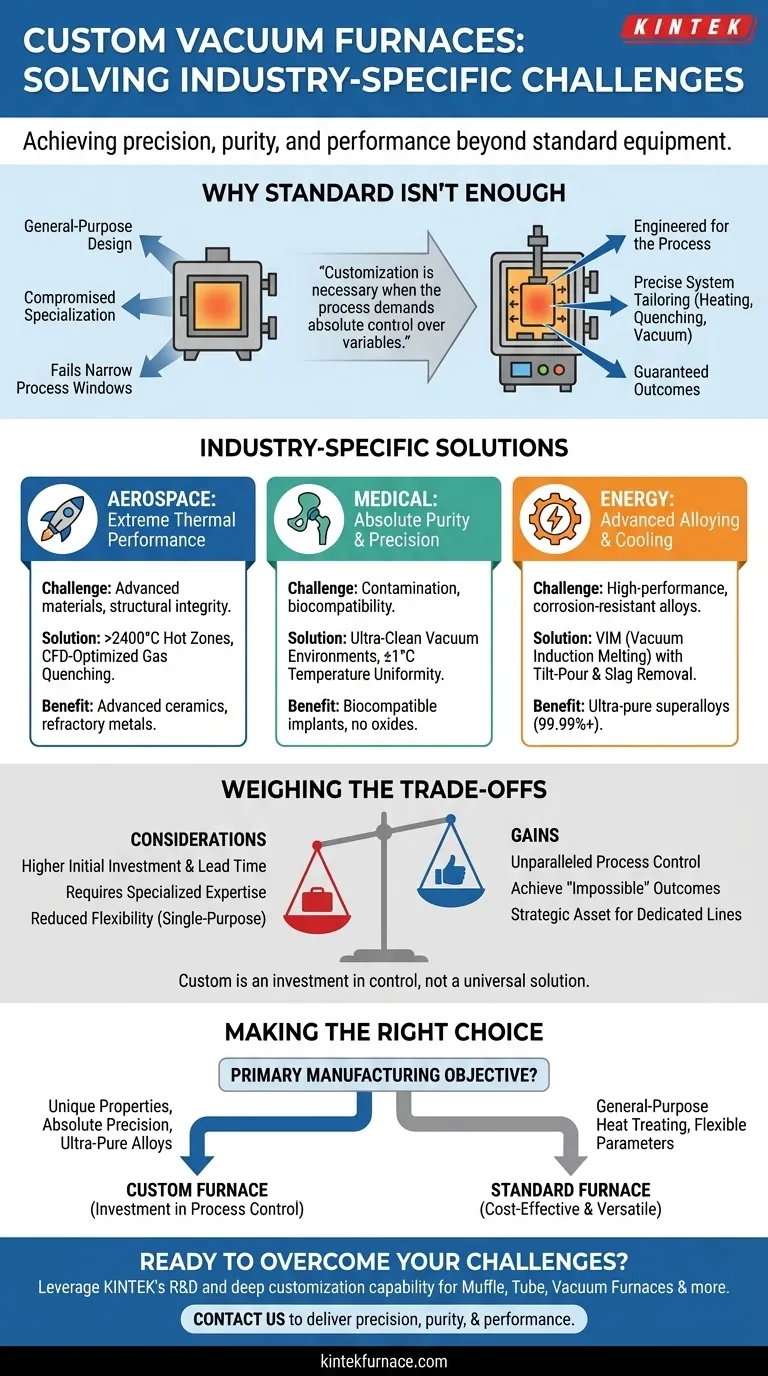

In essence, custom vacuum furnaces address industry-specific challenges by precisely tailoring their core systems—such as the heating elements, quenching mechanisms, and vacuum purity controls—to meet the non-negotiable process requirements of a specific application. This allows industries like aerospace, medical, and energy to achieve material properties, purity levels, and component consistency that are impossible with general-purpose equipment.

The decision to use a custom vacuum furnace is driven by necessity, not preference. When a manufacturing process demands absolute control over variables like temperature uniformity, cooling rates, or contamination, a standard furnace's generalized design becomes a liability, and customization is the only way to guarantee the required outcome.

Why a Standard Furnace Isn't Always Enough

Standard vacuum furnaces are designed to be versatile, serving a broad range of heat treatment applications. This versatility, however, comes from compromising on specialization.

When a specific material or process window is extremely narrow, these general-purpose designs can fail to meet the required specifications for quality, repeatability, and performance. Customization bridges this gap by engineering the furnace around the process itself.

The Demand for Extreme Thermal Performance

For many advanced materials, the exact temperature and its uniformity are critical. A deviation of just a few degrees can ruin a component's structural integrity.

Custom furnaces for the aerospace industry, for example, are often built with hot zones capable of exceeding 2400°C. This is necessary for processing advanced ceramics and refractory metals used in turbine blades and heat shields.

The Requirement for Absolute Purity

Contamination can be catastrophic, especially in medical and energy applications. The "vacuum" in a vacuum furnace is not a perfect void, and outgassing from furnace components can introduce impurities.

For medical devices like implants, custom furnaces provide ultra-clean vacuum environments and validated temperature uniformity of ±1°C. This ensures biocompatibility and prevents the formation of undesirable surface oxides or material phases.

The Challenge of Advanced Alloying and Cooling

Creating high-performance alloys or achieving specific microstructures often requires more than just heat. The melting, pouring, and cooling phases are just as important.

For the energy sector, custom vacuum induction melting (VIM) furnaces are used to create corrosion-resistant superalloys. These often feature integrated tilt-pour mechanisms and slag removal systems to achieve purities of 99.99% or higher.

Similarly, aerospace applications demand rapid and uniform cooling to lock in specific material properties. This is achieved with CFD-optimized gas quenching systems that are engineered specifically for the component's geometry and material, something a standard system cannot do.

Understanding the Trade-offs of Customization

While a custom furnace provides unparalleled process control, this specialization comes with significant considerations that must be weighed carefully. It is not a universally superior solution.

Higher Initial Investment and Lead Time

A furnace engineered from the ground up for a specific task will inherently have a higher upfront cost and a longer design and manufacturing lead time compared to an off-the-shelf model.

This investment must be justified by the value of the end product or the inability of standard equipment to meet critical quality thresholds.

The Need for Specialized Expertise

Operating a highly specialized piece of equipment requires more than general knowledge. A custom furnace is a complex, integrated system.

Operators must have professional training in vacuum technology, advanced heat treatment processes, and the specific electrical control systems of the furnace. Errors in operation can compromise both the equipment and the high-value products being processed.

Reduced Process Flexibility

A key trade-off for extreme optimization is a loss of flexibility. A furnace designed to perfectly heat-treat a specific turbine blade may be inefficient or completely unsuitable for processing a different component or material.

This makes a custom furnace a strategic asset for a dedicated production line, but a potential liability in a high-mix, low-volume R&D or job shop environment.

Making the Right Choice for Your Goal

The decision between a standard and custom furnace should be guided by your primary manufacturing objective and the acceptable margin of error in your process.

- If your primary focus is achieving unique material properties for aerospace: Customization is essential for integrating extreme temperatures with advanced, CFD-optimized quenching systems.

- If your primary focus is absolute process precision and repeatability for medical devices: A custom furnace is necessary to guarantee unparalleled temperature uniformity and a contamination-free environment.

- If your primary focus is producing ultra-pure, specialized alloys for the energy sector: A custom vacuum induction melting furnace with integrated pouring and purification is the only viable path.

- If your primary focus is general-purpose heat treating with flexible parameters: A standard furnace will likely provide a more cost-effective and versatile solution for your needs.

Ultimately, choosing a custom furnace is an investment in process control, enabling outcomes that standard equipment simply cannot guarantee.

Summary Table:

| Industry | Key Customization | Benefit |

|---|---|---|

| Aerospace | High-temp hot zones (>2400°C), CFD-optimized gas quenching | Achieves extreme thermal performance for advanced materials |

| Medical | Ultra-clean vacuum, ±1°C temperature uniformity | Ensures biocompatibility and prevents contamination |

| Energy | Vacuum induction melting with tilt-pour and slag removal | Produces ultra-pure alloys (99.99%+) for corrosion resistance |

Ready to overcome your industry's heat treatment challenges? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our custom vacuum furnaces can deliver the precision, purity, and performance your applications demand!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing