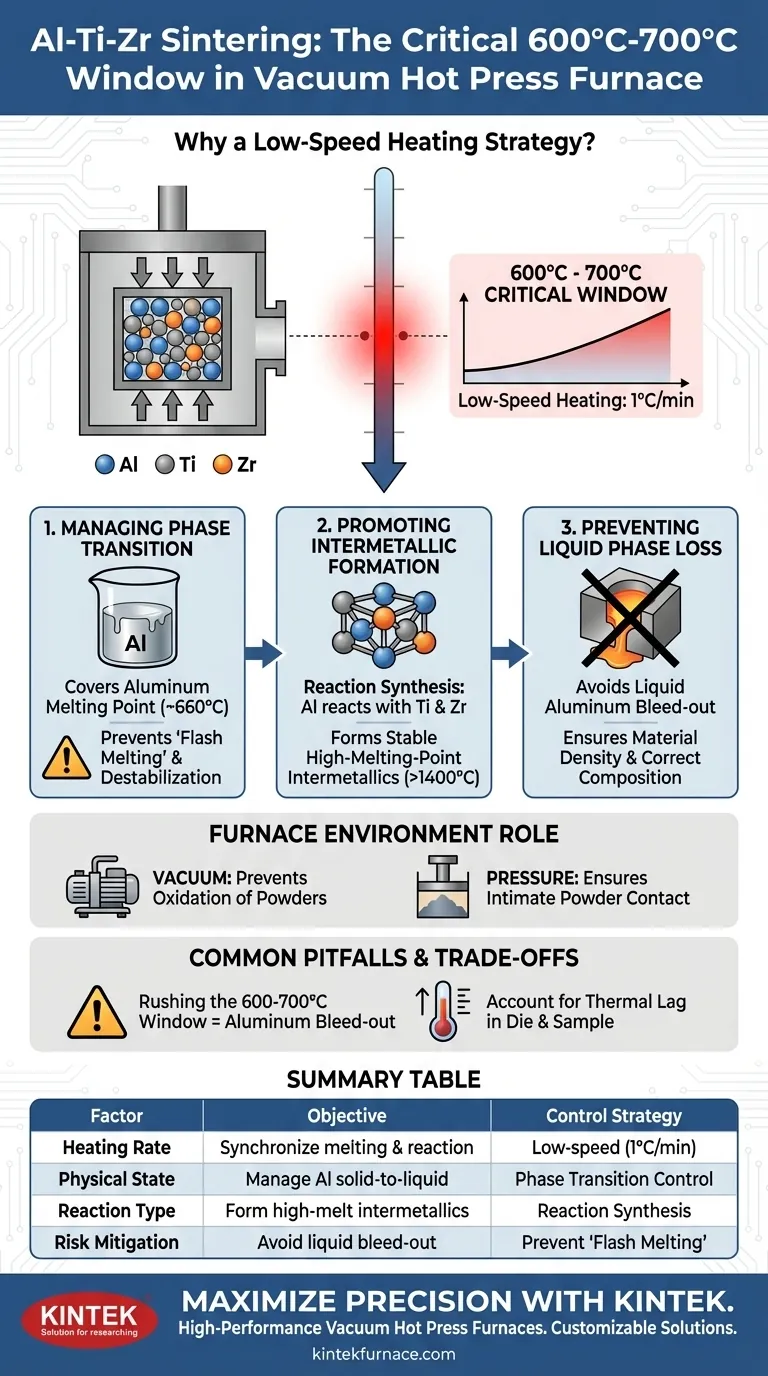

The critical 600°C to 700°C window in your heating profile corresponds directly to the melting point of aluminum. A low-speed heating strategy is implemented here to strictly manage the transition of aluminum from solid to liquid. By reducing the heating rate (typically to 1°C/min), you ensure that melting aluminum reacts immediately with titanium and zirconium powders to form stable, high-melting-point intermetallics, rather than flowing out of the matrix as a liquid.

The core objective is to synchronize the melting of aluminum with its chemical consumption. Slow heating allows the liquid aluminum to be captured via reaction synthesis, transforming it into heat-resistant compounds (>1400°C) and preventing the structural collapse that occurs if the liquid phase escapes.

The Mechanics of Reactive Sintering

Managing the Phase Transition

The temperature range of 600°C to 700°C covers the melting point of aluminum (approx. 660°C). In a mixed powder system (Al-Ti-Zr), this is the most volatile stage of the process.

If the furnace passes through this range too quickly, a large volume of liquid aluminum forms simultaneously. This "flash melting" can destabilize the powder compact before the chemical reactions can occur.

Promoting Intermetallic Formation

The goal of this specific heating stage is reaction synthesis. You want the aluminum to react with the Titanium and Zirconium to form new intermetallic compounds.

These resulting compounds have significantly higher melting points (exceeding 1400°C) than pure aluminum. By heating slowly, you allow the aluminum to melt locally and immediately react, effectively "locking" the aluminum into a solid, heat-resistant structure.

Preventing Liquid Phase Loss

If the heating rate is too aggressive, the reaction kinetics cannot keep up with the melting process. This results in an excess of unreacted liquid aluminum.

In a Vacuum Hot Press environment, this unreacted liquid is liable to flow out of the die or squeeze into pores improperly. This leads to a loss of material, deviated chemical composition, and ultimately, a failed sintering run.

The Role of the Furnace Environment

Program Control Precision

The Vacuum Hot Press Furnace is essential because it allows for programmable heating rates. This is not a linear blast of heat; it requires a specific "hold" or "slow ramp" instruction in the controller.

Maintaining a strict 1°C/min rate (or similar) ensures the thermal energy provided matches the reaction rate of the powders, rather than overwhelming them.

Vacuum and Pressure Synergy

While the temperature control manages the melting, the vacuum and pressure play supporting roles. The vacuum atmosphere prevents the oxidation of the sensitive metal powders (particularly aluminum and titanium).

Simultaneously, the mechanical pressure (e.g., 40.8 MPa) ensures the powders remain in intimate contact. This physical contact is crucial for the liquid aluminum to find and react with the Ti/Zr particles instantly upon melting.

Common Pitfalls and Trade-offs

The Risk of Rushing

It is tempting to increase the heating rate to reduce total cycle time. However, skipping or rushing the 600-700°C window is the primary cause of aluminum bleed-out.

If you see resolidified aluminum on your die or furnace floor, or if your final part has low density and poor stoichiometry, your ramp rate in this specific zone was likely too high.

Thermal Lag Considerations

Operators must account for the thermal mass of the die and the sample. The thermocouple reading may differ slightly from the core temperature of the sample.

A slow ramp rate helps minimize the thermal gradient between the outside and the inside of the sample, ensuring the reaction happens uniformly throughout the material, not just on the surface.

Making the Right Choice for Your Goal

When designing your sintering profile for Al-Ti-Zr composites, consider the following:

- If your primary focus is Compositional Accuracy: strictly adhere to the low-speed ramp (1°C/min) through the melting point to prevent any loss of the aluminum phase.

- If your primary focus is Material Density: ensure high mechanical pressure is applied effectively during this reaction phase to eliminate porosity as the phases transform.

- If your primary focus is Cycle Efficiency: optimize the ramp rates before 600°C (e.g., after the 400°C degassing stage) or after 700°C, but never compromise the speed within the critical melting window.

Success in this process relies on treating the aluminum melting point not just as a temperature to pass, but as a chemical reaction to manage.

Summary Table:

| Factor | 600°C - 700°C Control Strategy | Key Objective |

|---|---|---|

| Heating Rate | Low-speed (typically 1°C/min) | Synchronize melting with reaction kinetics |

| Physical State | Aluminum Phase Transition | Manage solid-to-liquid transformation |

| Reaction Type | Reaction Synthesis | Form high-melting-point (>1400°C) intermetallics |

| Risk Mitigation | Prevent "Flash Melting" | Avoid liquid aluminum bleed-out and material loss |

| Atmosphere | Vacuum & Pressure | Prevent oxidation and ensure intimate powder contact |

Maximize Your Sintering Precision with KINTEK

Don't let "aluminum bleed-out" ruin your complex material compositions. Success in Al-Ti-Zr sintering requires equipment that offers unmatched thermal control and precision programming.

Backed by expert R&D and manufacturing, KINTEK provides high-performance Vacuum Hot Press Furnaces, Muffle, Tube, Rotary, and CVD systems. Our lab high-temperature furnaces are fully customizable to meet your unique sintering profiles and research needs.

Ready to elevate your material synthesis? Contact our technical experts today to find the perfect furnace solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the key differences in maximum temperature between low vacuum and high vacuum furnaces? Unlock Higher Heat for Purity

- What are the typical vacuum levels for medium, high, and ultra-high vacuum furnaces? Optimize Your Process Efficiency

- In which industries is vacuum brazing aluminum commonly applied? Essential for Aerospace, Automotive, Electronics, and Medical

- What advantages do vacuum and modified atmosphere furnaces offer for sintering in 3D printing? Achieve Dense, High-Performance Parts

- What are some common applications of graphite in vacuum furnaces? Essential for High-Temp Processing

- What is the purpose of using screening equipment to pretreat magnesium slag before its recovery via vacuum distillation? Optimize Your Recovery Process

- Why is a vacuum arc-melting furnace preferred for Co-Ti-V quaternary superalloys? Ensure Purity & High-Temp Precision

- Why is vacuum carburizing suitable for high-performance carburizing steels? Achieve Superior Hardening with Precision Control