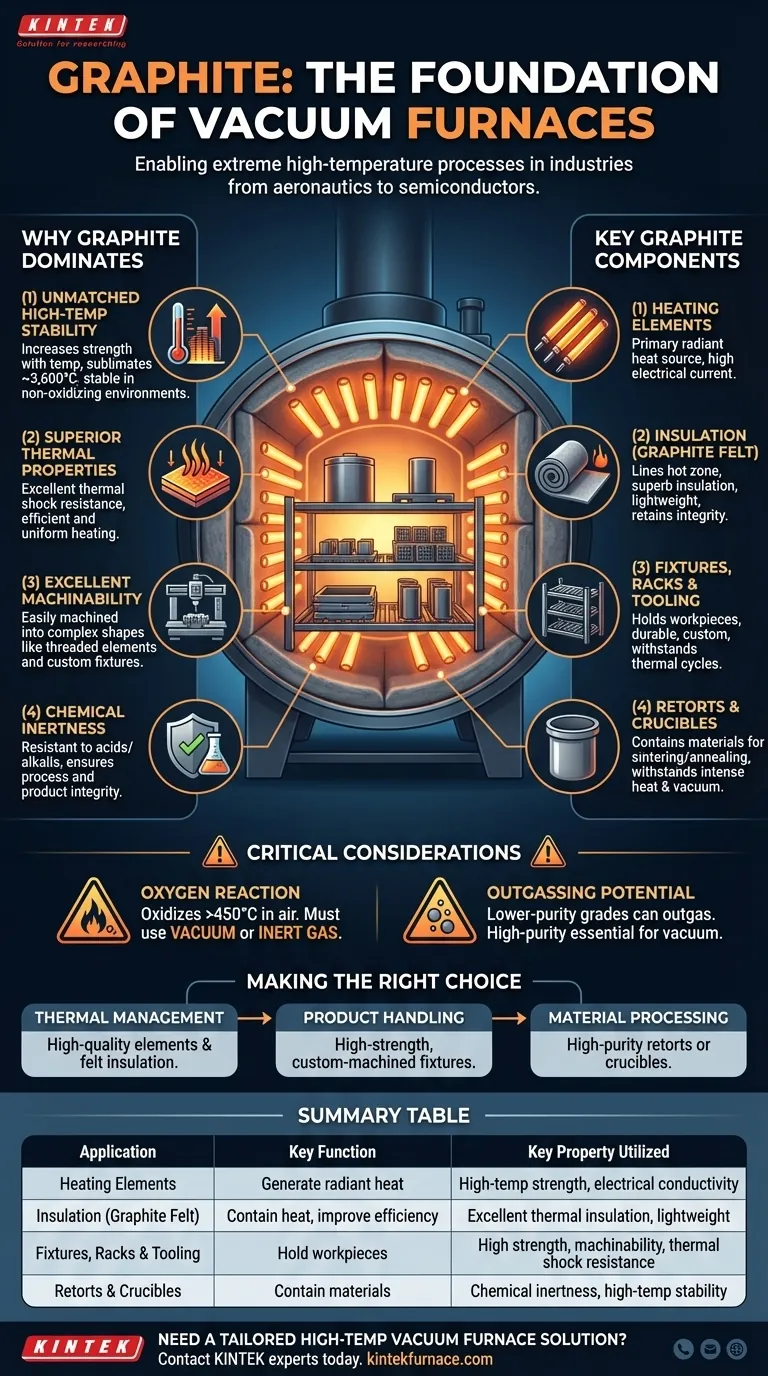

In vacuum furnaces, graphite is the foundational material that enables extreme high-temperature processes. Its most common applications are as heating elements that generate the heat, felt insulation that contains it, and the internal fixtures, racks, and retorts that hold the workpieces being treated. These components are essential for industries ranging from aeronautics to semiconductor manufacturing.

While many materials can handle high heat, graphite is uniquely suited for vacuum furnaces due to its extraordinary ability to increase in strength as temperature rises, all while remaining stable in a non-oxidizing environment. Understanding its properties is key to understanding modern high-temperature material processing.

Why Graphite Dominates in Vacuum Furnaces

Graphite isn't just one option among many; its specific combination of properties makes it the default choice for the hottest zones of vacuum and inert atmosphere furnaces.

Unmatched High-Temperature Stability

Graphite does not melt at atmospheric pressure. Instead, it sublimes (turns directly into a gas) at temperatures approaching 3,600°C.

Critically, its mechanical strength actually increases with temperature, peaking around 2,500°C. This is the opposite of metals, which weaken as they get hotter.

Superior Thermal Properties

Graphite exhibits excellent resistance to thermal shock. It can withstand rapid heating and cooling cycles without cracking, a vital attribute for furnace components.

Its large radiation area also contributes to efficient and uniform heating within the furnace chamber.

Excellent Machinability and Strength

Despite its strength, graphite is relatively soft and can be easily machined into complex shapes like threaded heating elements or intricate product carriers.

This allows for the creation of custom fixtures and furnace parts tailored to specific processes like heat treating, brazing, or sintering.

Chemical Inertness

Graphite is highly resistant to chemical attack from acids, alkalis, and most corrosive agents, ensuring the integrity of both the furnace and the product. This makes it ideal for containing materials during sensitive processes.

A Breakdown of Key Graphite Components

These fundamental properties translate directly into the critical roles graphite plays inside a furnace.

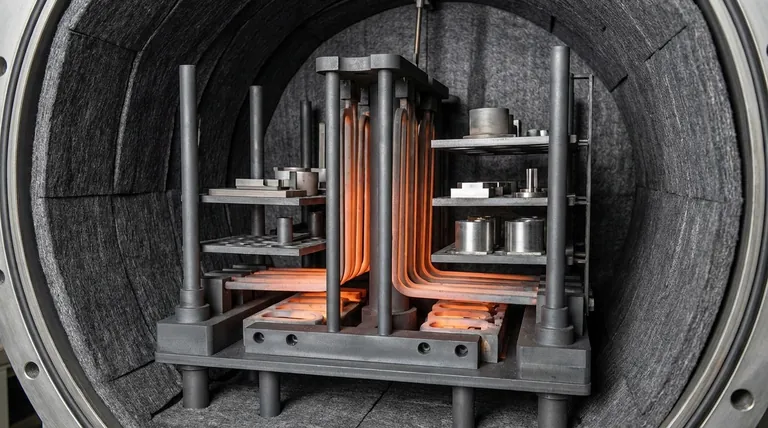

Heating Elements

Graphite is the primary source of radiant heat in most vacuum furnaces. It is machined into rods or plates that glow when a high electrical current is passed through them, efficiently heating the furnace chamber.

Insulation (Graphite Felt)

To contain this intense heat, the furnace "hot zone" is lined with graphite felt. This material provides superb thermal insulation, is lightweight, and retains its structural integrity at extreme temperatures.

This insulation package is critical for minimizing heat loss and improving the energy efficiency of the furnace.

Fixtures, Racks, and Tooling

Workpieces cannot simply be placed on the furnace floor. They are held in position by graphite fixtures, grids, and support posts.

The material's high-temperature strength and machinability allow for the creation of durable, custom tooling that will not warp or fail during a heating cycle.

Retorts and Crucibles

For processes like sintering powders or annealing small parts, graphite retorts or crucibles act as containers. They hold the material securely and can withstand the intense heat and vacuum conditions without reacting with the product.

Understanding the Trade-offs and Limitations

While graphite is exceptional, its use is not without critical considerations. Its properties define not only its advantages but also its operational requirements.

The Critical Need for a Controlled Atmosphere

Graphite's primary limitation is its reaction with oxygen at high temperatures. In the presence of air, graphite will begin to oxidize (burn) at temperatures above 450°C.

This is precisely why it is used in vacuum or inert gas (like argon) furnaces. By removing oxygen, the furnace atmosphere protects the graphite components from degradation, allowing them to operate up to 3,000°C.

Potential for Outgassing

Lower-purity grades of graphite can contain trapped moisture or binders that will turn to gas (outgas) when heated under vacuum. This can compromise the vacuum level or contaminate sensitive materials.

Therefore, selecting the correct, high-purity grade of graphite is essential for high-vacuum applications, especially in electronics and semiconductor manufacturing.

Making the Right Choice for Your Application

Selecting the right type and form of graphite depends entirely on your operational goal.

- If your primary focus is thermal management: Your priority is high-quality heating elements and a properly designed graphite felt insulation package to ensure temperature uniformity and efficiency.

- If your primary focus is product handling: You need custom-machined fixtures, racks, and tooling made from a high-strength grade of graphite that can withstand repeated thermal cycles.

- If your primary focus is material processing: You require high-purity graphite retorts or crucibles that will contain your material without reacting with it or introducing contaminants.

Ultimately, graphite's unique behavior at extreme temperatures makes it an irreplaceable material in the world of advanced thermal processing.

Summary Table:

| Application | Key Function | Key Property Utilized |

|---|---|---|

| Heating Elements | Generate radiant heat | High-temperature strength, electrical conductivity |

| Insulation (Graphite Felt) | Contain heat, improve efficiency | Excellent thermal insulation, lightweight |

| Fixtures, Racks & Tooling | Hold workpieces in place | High strength, machinability, thermal shock resistance |

| Retorts & Crucibles | Contain materials during processing | Chemical inertness, high-temperature stability |

Need a high-temperature vacuum furnace solution tailored to your specific process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced furnace solutions for diverse laboratories. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities. We can help you select or design the perfect graphite components—from heating elements to custom fixtures—to precisely meet your unique experimental requirements, ensuring optimal performance and longevity in your high-temperature applications.

Contact our experts today to discuss how we can enhance your thermal processing capabilities!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures