At its core, vacuum carburizing is uniquely suited for high-performance steels because its precision control over temperature, gas flow, and time allows for the creation of a highly uniform and optimized hardened case, which is critical for these advanced alloys. The process operates in a clean, oxygen-free environment, which prevents surface oxidation and allows carbon to diffuse into the steel with unparalleled consistency. This leads directly to superior metallurgical properties and significantly reduced part distortion compared to traditional methods.

The fundamental advantage of vacuum carburizing is its ability to precisely manage the carbon diffusion process without the interference of surface oxidation. This level of control is what unlocks the full potential of high-performance alloys, resulting in components that are not only stronger but also dimensionally more stable after heat treatment.

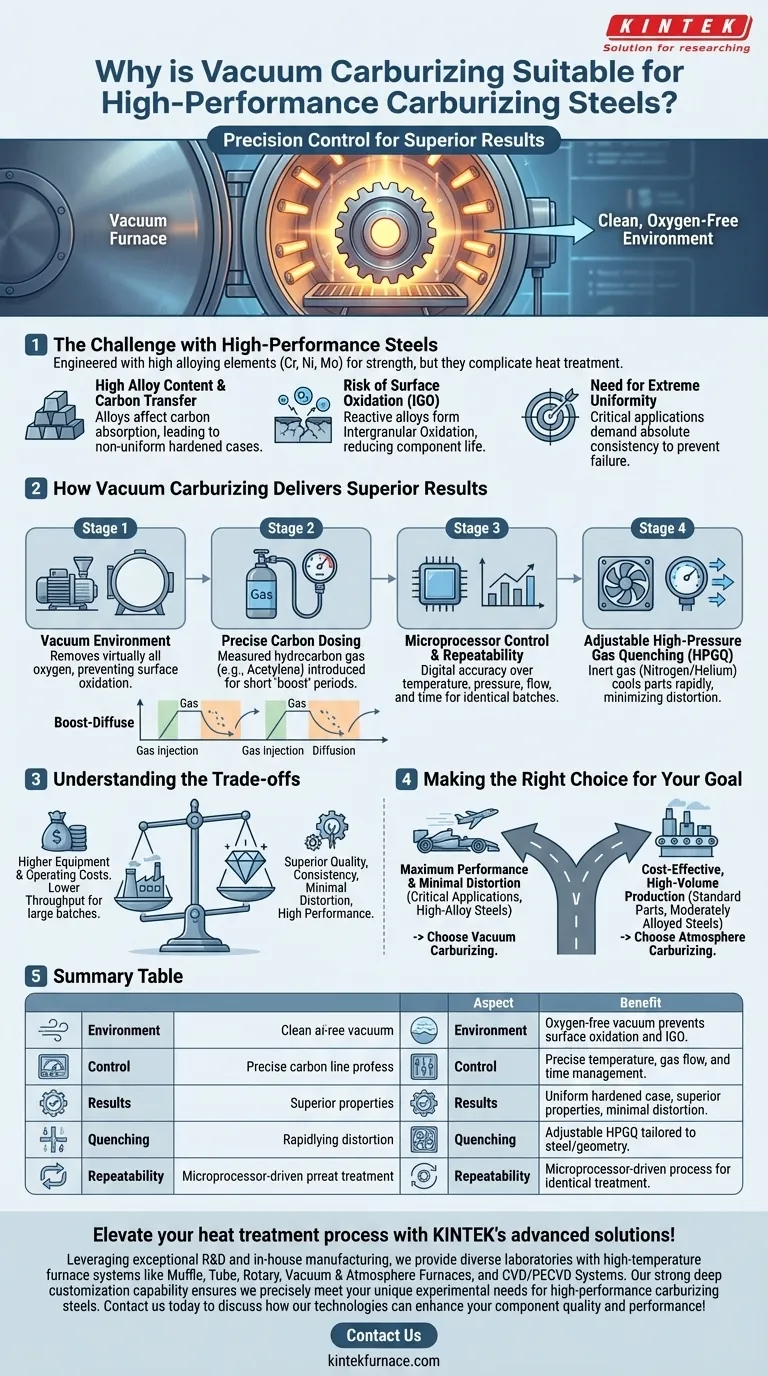

The Challenge with High-Performance Steels

High-performance carburizing steels are engineered with significant amounts of alloying elements like chromium, nickel, and molybdenum. While these elements provide superior strength and toughness, they also complicate the heat treatment process.

High Alloy Content and Carbon Transfer

Alloying elements can affect how readily carbon is absorbed at the steel's surface. Traditional atmosphere carburizing can struggle to deliver a consistent carbon concentration, leading to a non-uniform hardened case and unpredictable performance.

The Risk of Surface Oxidation

In conventional furnaces, a protective atmosphere is used to prevent the steel from reacting with oxygen. However, this atmosphere is imperfect. The alloying elements in high-performance steels are often highly reactive with any trace oxygen, forming a microscopic oxide layer that can inhibit or block carbon absorption. This phenomenon is known as intergranular oxidation (IGO), a primary cause of reduced component life.

The Need for Extreme Uniformity

Applications for these steels—such as aerospace gears, high-performance racing components, and specialized bearings—demand absolute consistency. Any variation in case depth or hardness across a part's surface can create a stress concentration point, leading to premature failure under high loads.

How Vacuum Carburizing Delivers Superior Results

Vacuum carburizing fundamentally redesigns the process to overcome the limitations of atmospheric methods. It is a non-equilibrium, "boost-diffuse" process conducted in a series of precise, digitally controlled steps.

The Role of the Vacuum Environment

The process begins by placing parts in a furnace and pumping it down to a near-perfect vacuum. This step removes virtually all oxygen and other atmospheric gases. By creating a clean slate, the process ensures that the steel surface is perfectly receptive to carbon and that no surface oxidation can occur.

Precise Carbon Dosing

Instead of a constant "soak" in a carbon-rich gas, vacuum carburizing introduces a precise, measured amount of a hydrocarbon gas (typically acetylene) for a short period. This "boost" phase quickly supersaturates the surface with carbon. The gas is then shut off, and a diffusion phase begins, allowing the absorbed carbon to migrate deeper into the part under precisely controlled temperature and time. This cycle can be repeated to achieve the exact desired carbon profile.

Microprocessor Control and Repeatability

The entire process is governed by a microprocessor. Every variable—temperature, pressure, gas flow rate, and time—is monitored and controlled with digital accuracy. This ensures that every part in a batch, and every batch over time, receives an identical treatment, guaranteeing consistent and reproducible results.

Adjustable High-Pressure Gas Quenching (HPGQ)

After carburizing, the parts must be quenched (rapidly cooled) to achieve final hardness. Instead of using oil, which causes significant distortion and requires cleaning, vacuum furnaces use high-pressure gas quenching. The pressure and velocity of an inert gas like nitrogen or helium can be precisely adjusted, allowing the cooling rate to be tailored to the specific steel and part geometry, thereby minimizing distortion.

Understanding the Trade-offs

While the benefits are clear, vacuum carburizing is not a universal replacement for all heat treatment. Understanding its limitations is key to making an informed decision.

Equipment and Operating Costs

Vacuum furnaces represent a significant capital investment compared to traditional atmosphere furnaces. The high-purity gases and sophisticated control systems also contribute to higher operational costs on a per-part basis.

Batch Size and Throughput

Generally, vacuum furnaces are designed for smaller batch sizes than large, continuous atmospheric furnaces. For manufacturers producing immense quantities of less critical components, the lower throughput of a vacuum furnace can be a limiting factor.

Making the Right Choice for Your Goal

The decision to use vacuum carburizing should be driven by the performance requirements of the final component.

- If your primary focus is maximum performance and minimal distortion: Vacuum carburizing is the definitive choice for critical applications using high-alloy steels, such as in aerospace, motorsports, or high-end industrial machinery.

- If your primary focus is cost-effective, high-volume production of standard parts: Traditional atmosphere carburizing on moderately alloyed steels may remain the more economical solution, provided its inherent variability is acceptable for the application.

Ultimately, adopting vacuum carburizing is a strategic decision to prioritize component quality and predictability over raw production volume.

Summary Table:

| Aspect | Vacuum Carburizing Benefit |

|---|---|

| Environment | Oxygen-free vacuum prevents surface oxidation and intergranular oxidation (IGO) |

| Control | Precise temperature, gas flow, and time management for consistent carbon diffusion |

| Results | Uniform hardened case, superior metallurgical properties, and minimal part distortion |

| Quenching | Adjustable high-pressure gas quenching (HPGQ) tailored to steel and part geometry |

| Repeatability | Microprocessor-driven process ensures identical treatment across batches |

Elevate your heat treatment process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for high-performance carburizing steels. Contact us today to discuss how our technologies can enhance your component quality and performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity