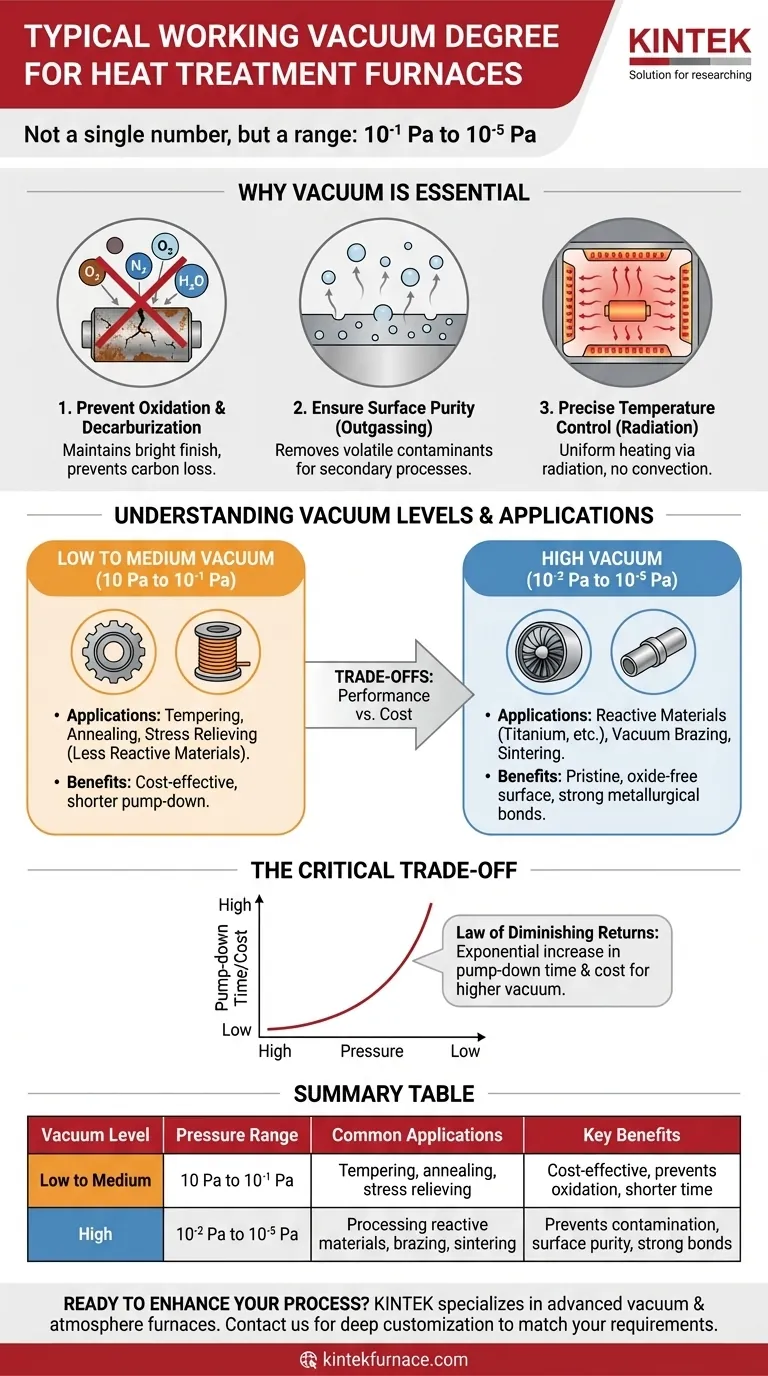

While a single number is often cited, the typical working vacuum for a heat treatment furnace is not one specific value but a range, typically from 10⁻¹ Pa down to 10⁻⁵ Pa. The exact level required is dictated by the specific material being processed and the desired outcome, as a higher vacuum provides greater protection against atmospheric contamination.

The core takeaway is that the "correct" vacuum level is not about achieving the lowest possible pressure. It is a calculated engineering decision to create an environment pure enough to prevent unwanted chemical reactions—like oxidation—at a specific temperature, balancing process requirements against time and cost.

Why a Vacuum is Essential in Heat Treatment

The primary purpose of using a vacuum is to remove the atmospheric gases—primarily oxygen, nitrogen, and water vapor—that cause undesirable reactions at elevated temperatures. This controlled environment provides several distinct advantages over traditional atmosphere furnaces.

Preventing Oxidation and Decarburization

At high temperatures, most metals readily react with oxygen, forming a layer of oxide scale on the surface. A vacuum furnace removes the vast majority of oxygen molecules, preventing oxidation and ensuring the part maintains a bright, clean finish. This is also critical for preventing decarburization, where carbon leaves the surface of steel, softening it and degrading its mechanical properties.

Ensuring Surface Purity

The vacuum environment does more than just prevent new contaminants from forming. Under vacuum, existing volatile contaminants on the material's surface can "outgas" or evaporate away during the heating cycle. This results in an exceptionally clean surface, which is critical for secondary processes like brazing or coating.

Enabling Precise Temperature Control

In a near-vacuum, heat transfer occurs primarily through radiation, not convection. This eliminates hot or cold spots caused by circulating gases, allowing for extremely uniform heating and cooling. This precise thermal control is essential for achieving specific microstructures and material properties in sensitive alloys.

Understanding Vacuum Levels and Their Applications

The term "vacuum" covers a wide range of pressures. For heat treatment, these are generally categorized into low and high vacuum ranges, each suited for different tasks.

Low to Medium Vacuum (10 Pa to 10⁻¹ Pa)

This range is sufficient for many general-purpose heat treatments. It effectively removes enough oxygen to prevent significant oxidation on less reactive materials during processes like tempering, annealing, and stress relieving. It offers a good balance of protection and relatively short pump-down times.

High Vacuum (10⁻² Pa to 10⁻⁵ Pa)

This level of vacuum is required for more sensitive applications. Processing highly reactive materials like titanium, refractory metals, and certain stainless steels demands a high vacuum to prevent any trace contamination. It is also the standard for processes like vacuum brazing and sintering, where an absolutely pristine, oxide-free surface is non-negotiable for achieving a strong metallurgical bond.

The Critical Trade-offs: Performance vs. Cost

Choosing a vacuum level is an economic and operational decision, not just a technical one. Aiming for the highest possible vacuum is not always the best strategy.

The Law of Diminishing Returns

Achieving a higher vacuum (a lower pressure) requires more sophisticated and expensive pumping systems (e.g., adding a diffusion or turbomolecular pump). More importantly, the pump-down time increases exponentially as you try to remove the final few molecules of gas from the chamber.

Matching the Vacuum to the Process

The goal is to use a vacuum level that is sufficient for the task. Using a high vacuum system for a simple stress-relieving cycle on plain carbon steel is inefficient and costly. Conversely, attempting to braze a reactive alloy in a low vacuum furnace will likely result in a failed, oxidized joint. The material, temperature, and process objective must dictate the vacuum requirement.

Selecting the Right Vacuum for Your Process

Your choice should be directly informed by your material and your goal. Consider the required level of surface purity and the reactivity of the alloy at its processing temperature.

- If your primary focus is general-purpose treatments (e.g., stress relief, tempering low-alloy steels): A low-to-medium vacuum (around 10 Pa to 10⁻¹ Pa) is typically sufficient and cost-effective.

- If your primary focus is processing reactive materials (e.g., titanium, specialty alloys, tool steels): A high vacuum (10⁻² Pa to 10⁻⁵ Pa) is necessary to prevent contamination and ensure material integrity.

- If your primary focus is high-purity bonding (e.g., vacuum brazing, diffusion bonding, sintering): You must use a high vacuum (typically 10⁻³ Pa or lower) to guarantee an oxide-free surface for proper metallurgical joining.

Ultimately, selecting the appropriate vacuum level is a deliberate choice to create the ideal invisible shield for your material.

Summary Table:

| Vacuum Level | Pressure Range | Common Applications | Key Benefits |

|---|---|---|---|

| Low to Medium | 10 Pa to 10⁻¹ Pa | Tempering, annealing, stress relieving of low-alloy steels | Cost-effective, prevents oxidation, shorter pump-down times |

| High | 10⁻² Pa to 10⁻⁵ Pa | Processing reactive materials (e.g., titanium), vacuum brazing, sintering | Prevents contamination, ensures surface purity, enables strong metallurgical bonds |

Ready to enhance your heat treatment processes with the perfect vacuum solution? KINTEK specializes in advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratory needs. With our exceptional R&D and in-house manufacturing, we offer deep customization to precisely match your unique experimental requirements—whether you're working with reactive alloys or high-purity bonding applications. Contact us today to discuss how our expertise can optimize your results and boost efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance