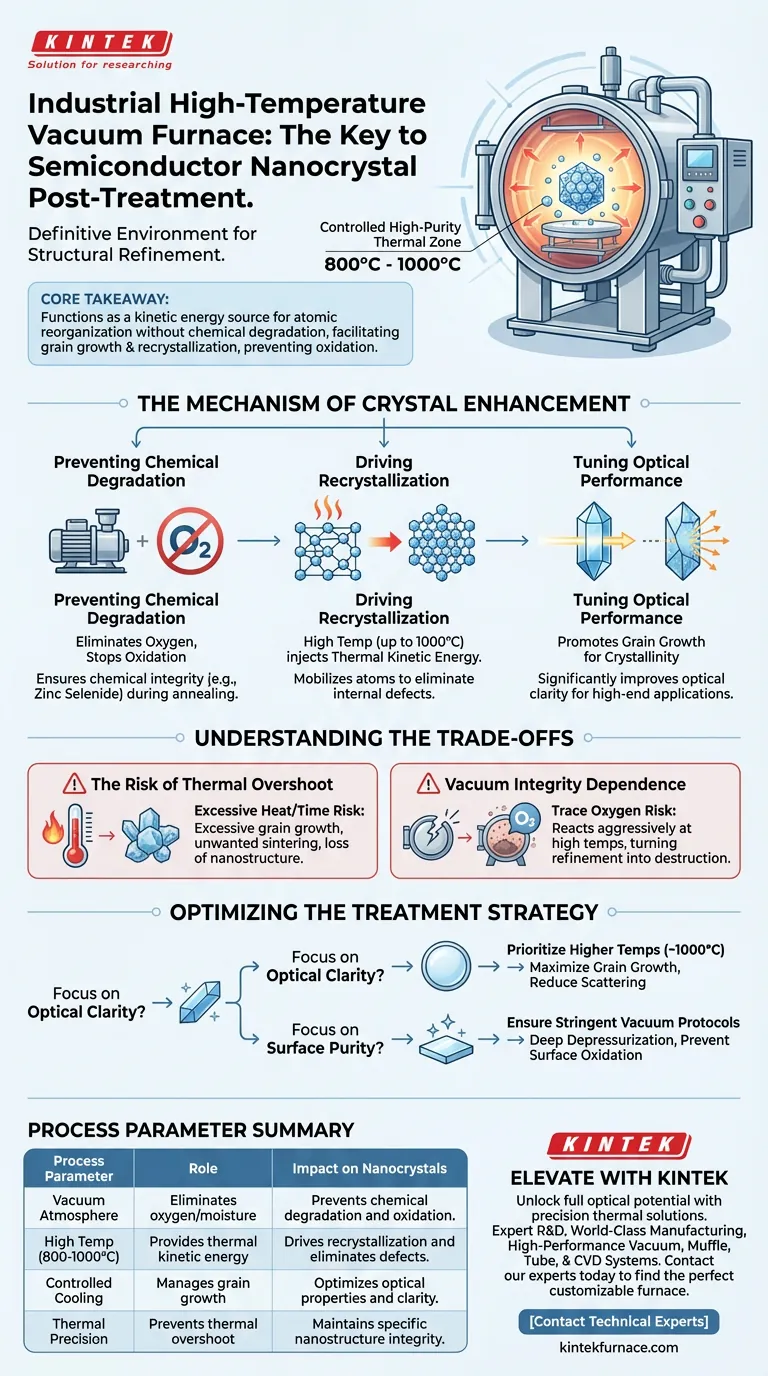

An industrial high-temperature vacuum furnace serves as the definitive environment for structural refinement in the post-treatment of semiconductor nanocrystals. It creates a controlled, high-purity thermal zone—typically operating between 800°C and 1000°C—that drives the transition from raw material to high-performance optical component.

Core Takeaway The furnace functions as a kinetic energy source that reorganizes atomic structures without chemical degradation. By combining high heat with a vacuum atmosphere, it facilitates necessary grain growth and recrystallization while strictly preventing the oxidation that would otherwise ruin the material's optical properties.

The Mechanism of Crystal Enhancement

Preventing Chemical Degradation

The primary challenge in treating semiconductor nanocrystals, such as zinc selenide, is their reactivity at high temperatures.

In a standard atmosphere, the heat required for treatment would cause immediate, uncontrolled oxidation. The vacuum furnace eliminates oxygen from the equation, ensuring the chemical integrity of the sample remains intact throughout long annealing cycles.

Driving Recrystallization

The furnace utilizes high temperatures (up to 1000°C) to inject thermal kinetic energy into the nanocrystals.

This energy mobilizes atoms within the material, allowing them to rearrange into a more ordered structure. This process, known as recrystallization, eliminates internal defects and stresses accumulated during earlier synthesis stages.

Tuning Optical Performance

The ultimate goal of this post-treatment is the enhancement of optical properties.

As the material recrystallizes, the process promotes grain growth. Larger, defect-free grains significantly improve the material's crystallinity. This structural perfection is directly responsible for the superior optical performance required in high-end semiconductor applications.

Understanding the Trade-offs

The Risk of Thermal Overshoot

While heat is necessary for ordering the crystal lattice, excessive thermal energy can be detrimental.

If the temperature exceeds the material's tolerance or the cycle is too long, you risk excessive grain growth or unwanted sintering. This can lead to a loss of the specific nanostructure characteristics you intended to preserve.

Vacuum Integrity Dependence

The success of the entire process hinges on the quality of the vacuum.

At 1000°C, even trace amounts of oxygen due to a minor leak or insufficient pump-down will react aggressively with the semiconductor material. This turns the furnace from a refinement tool into a destructive environment, potentially ruining the entire batch.

Optimizing the Treatment Strategy

To maximize the efficacy of the post-treatment process, align your furnace parameters with your specific material goals:

- If your primary focus is Optical Clarity: Prioritize higher temperatures (near 1000°C) to maximize grain growth and reduce scattering centers within the crystal lattice.

- If your primary focus is Surface Purity: Ensure your vacuum protocols are stringent, focusing on deep depressurization to prevent any surface oxidation during the annealing cycle.

The industrial vacuum furnace is not just a heater; it is a precision instrument for dictating the final quality and efficiency of semiconductor materials.

Summary Table:

| Process Parameter | Role in Post-Treatment | Impact on Nanocrystals |

|---|---|---|

| Vacuum Atmosphere | Eliminates oxygen/moisture | Prevents chemical degradation and oxidation |

| High Temp (800-1000°C) | Provides thermal kinetic energy | Drives recrystallization and eliminates defects |

| Controlled Cooling | Manages grain growth | Optimizes optical properties and clarity |

| Thermal Precision | Prevents thermal overshoot | Maintains specific nanostructure integrity |

Elevate Your Semiconductor Research with KINTEK

Unlock the full optical potential of your materials with KINTEK’s precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum, Muffle, Tube, and CVD systems designed specifically for the rigorous demands of semiconductor post-treatment.

Whether you need strictly controlled atmospheres for grain growth or customizable high-temp furnaces for unique nanocrystal synthesis, KINTEK delivers the reliability your lab requires.

Ready to refine your process? Contact our technical experts today to find the perfect customizable furnace for your unique needs.

Visual Guide

References

- Aiman Akylbekovа, А. Usseinov. RAMAN ANALYSIS OF NANOCRYSTALS BASED ON ZINC SELENIDE. DOI: 10.52676/1729-7885-2023-4-77-84

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is vacuum furnace brazing popular? Achieve Strong, Clean Joints for High-Performance Applications

- How does a high vacuum drying system facilitate the drying of MgAlhfip? Ensure Purity for Magnesium Electrolytes

- What role does a vacuum sintering furnace play in fine ceramic component production? Achieve High-Purity, Dense Ceramics

- What are the primary differences in sintering strategies for ceramic membranes? Optimize Your Thermal Processing

- What are the main types of vacuum furnaces classified by use? Find the Perfect Fit for Your Thermal Process

- What are the different types of vacuum furnaces? Find the Perfect Fit for Your Process

- How is a high-temperature resistance furnace used in molten salt corrosion experiments? Achieve Precision Stability

- What is vacuum brazing used for? Achieve Clean, Strong, and Distortion-Free Joints