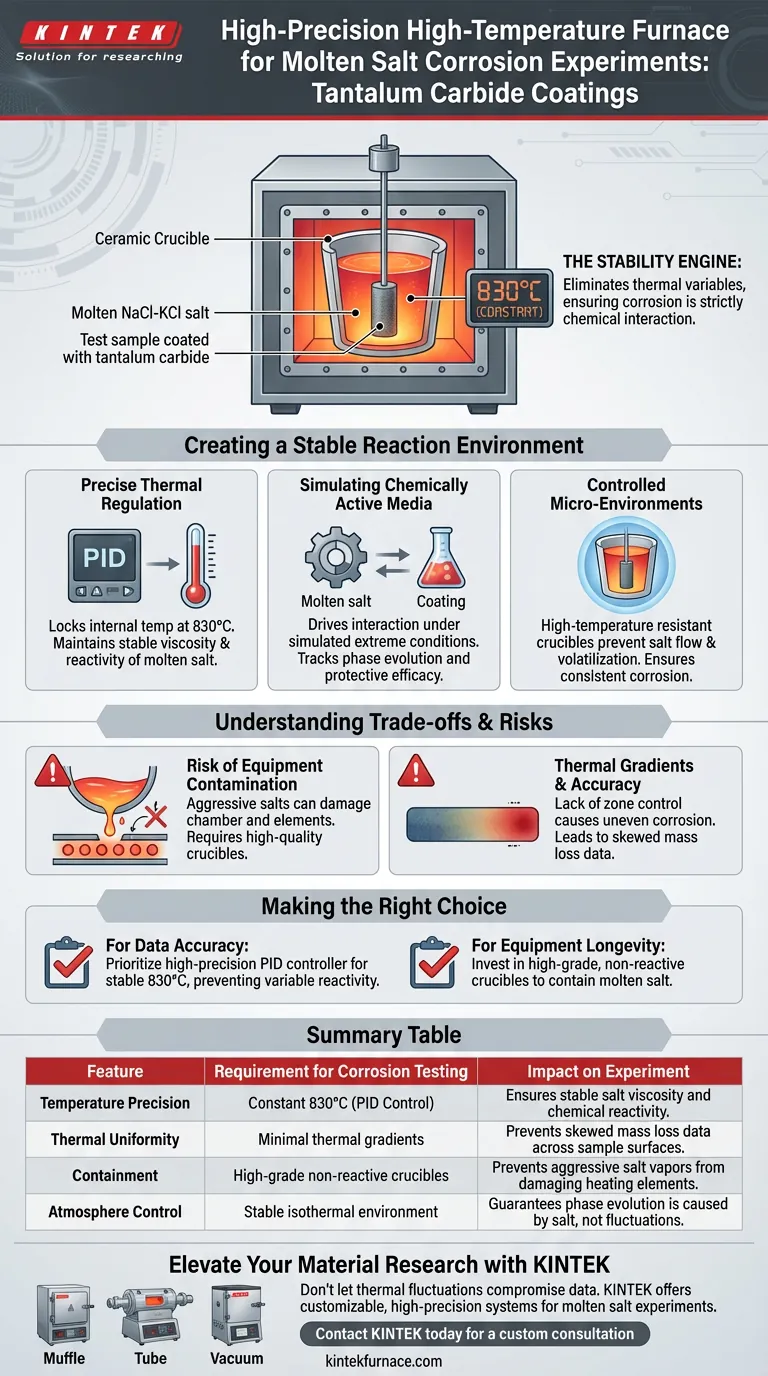

A high-precision high-temperature resistance furnace functions as the critical controlled environment for testing the durability of tantalum carbide (TaC) coatings. By maintaining a constant temperature of approximately 830°C, the furnace ensures that NaCl-KCl mixed salts remain in a stable, molten state, allowing researchers to accurately measure mass loss and phase evolution under simulated extreme operating conditions.

Core Takeaway The furnace is not merely a heat source; it is a stability engine. Its primary role is to eliminate thermal variables, ensuring that any degradation observed in the coating is strictly a result of chemical interaction with the molten salt, rather than fluctuations in the operating environment.

Creating a Stable Reaction Environment

The validity of a corrosion experiment relies entirely on the consistency of the environment. A high-precision resistance furnace achieves this through specific thermal and containment mechanisms.

Precise Thermal Regulation

The furnace uses a control system to lock the internal temperature at 830°C.

This precision is non-negotiable because the viscosity and reactivity of molten salts change drastically with temperature shifts.

By maintaining an isothermal environment, the furnace ensures the NaCl-KCl salt mix remains fluid and chemically active without overheating the substrate.

Simulating Chemically Active Media

The goal is to replicate the "extreme operating conditions" tantalum coatings will face in the real world.

The furnace heat drives the interaction between the molten salt and the carburized layer.

This allows researchers to track phase evolution—how the chemical structure of the coating changes over time—and quantify the protective efficacy of the coating.

Controlled Micro-Environments

To ensure the salt acts uniformly on the coating, samples are typically placed within high-temperature resistant crucibles.

These crucibles create a stable micro-environment around the sample, preventing the molten salts from flowing away or volatilizing unevenly.

This setup guarantees that the corrosion is consistent across the surface area of the test sample.

Understanding the Trade-offs and Risks

While resistance furnaces are essential for these experiments, they present specific operational challenges that can compromise data or equipment.

Risk of Equipment Contamination

Molten salts like NaCl-KCl are highly aggressive.

If the salt volatilizes or flows out of the crucible, it can contaminate the furnace chamber and damage heating elements.

Using high-quality crucibles is essential to prevent the salt from contacting the furnace's internal components.

Thermal Gradients and Accuracy

Not all resistance furnaces provide perfectly uniform heat distribution.

If a furnace lacks precise zone control, thermal gradients may form, causing one end of a sample to corrode faster than the other.

This leads to skewed mass loss data that does not accurately reflect the material's performance.

Making the Right Choice for Your Experiment

To maximize the reliability of your tantalum carbide corrosion testing, consider these specific priorities:

- If your primary focus is Data Accuracy: Ensure your furnace features a high-precision PID controller to maintain the 830°C setpoint with minimal fluctuation, preventing variable salt reactivity.

- If your primary focus is Equipment Longevity: Invest in high-grade, non-reactive crucibles to contain the molten NaCl-KCl mixture, preventing chamber contamination and heating element failure.

Reliable corrosion data is the product of precise thermal stability and rigorous containment.

Summary Table:

| Feature | Requirement for Corrosion Testing | Impact on Experiment |

|---|---|---|

| Temperature Precision | Constant 830°C (PID Control) | Ensures stable salt viscosity and chemical reactivity. |

| Thermal Uniformity | Minimal thermal gradients | Prevents skewed mass loss data across sample surfaces. |

| Containment | High-grade non-reactive crucibles | Prevents aggressive salt vapors from damaging heating elements. |

| Atmosphere Control | Stable isothermal environment | Guarantees phase evolution is caused by salt, not fluctuations. |

Elevate Your Material Research with KINTEK

Don't let thermal fluctuations compromise your corrosion data. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, and Vacuum furnace systems specifically designed to handle the rigors of molten salt experiments. Whether you are testing tantalum carbide coatings or developing new alloys, our customizable high-temperature solutions provide the stability and durability your lab requires.

Ready to optimize your testing environment? Contact KINTEK today for a custom consultation and ensure your research is built on a foundation of precision.

Visual Guide

References

- Xuming Lv, Pingze Zhang. The Effects of Surface Plasma Carburization on the Microstructure and Molten Salt Corrosion Resistance of Ta. DOI: 10.3390/coatings14121570

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does the atmosphere in a high vacuum sintering furnace affect 17-4PH properties? Optimize Density and Hardness

- Why is precise temperature control a significant feature of a vacuum furnace? Unlock Repeatable, High-Quality Results

- What key process conditions do high-temperature vacuum furnaces provide for the thermal hydrogen treatment of Ti–6Al–4V?

- Why must Ge-S-Cd alloy tablets be placed in vacuum-sealed capsules? Ensure High-Purity Chalcogenide Synthesis

- What are the benefits of using a vacuum environment in heat treatment? Achieve Superior Metallurgical Control

- How can the cooling rate of vacuum sintering be increased? Boost Efficiency with Gas-Assisted Cooling

- Why is a high-vacuum heat treatment furnace essential for superalloys? Unlock Peak Material Integrity

- Why is removing oxygen important in a vacuum furnace? Prevent Oxidation for Superior Metal Quality