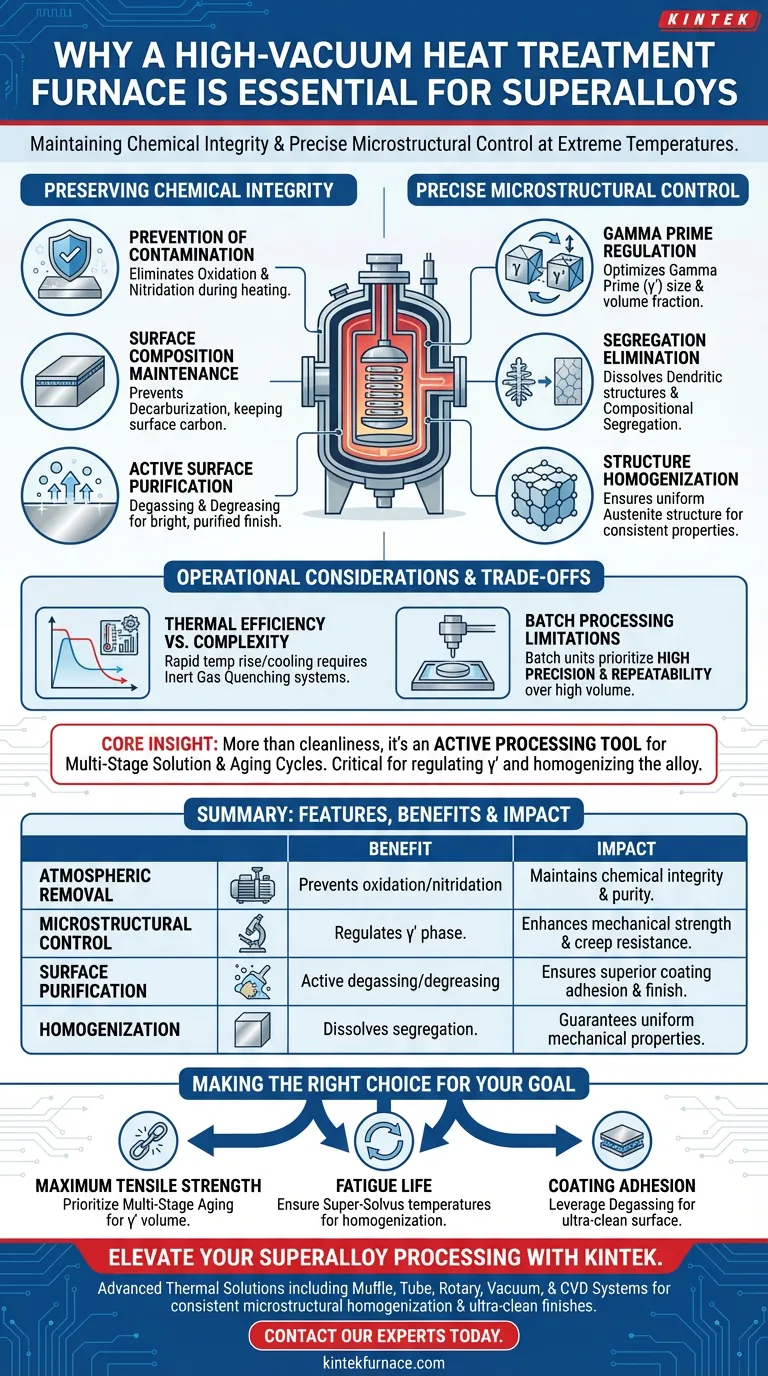

A high-vacuum heat treatment furnace is the prerequisite for processing superalloys because it provides the only environment capable of sustaining the material's chemical integrity at extreme temperatures. By eliminating atmospheric gases, it prevents oxidation and nitridation while enabling the precise thermal cycles required to manipulate the alloy's microstructure for maximum strength.

Core Insight: The value of a high-vacuum furnace extends beyond simple cleanliness; it is an active processing tool that enables multi-stage solution and aging cycles. These cycles are critical for regulating the gamma prime ($\gamma'$) reinforcing phase and homogenizing the alloy, ensuring the mechanical properties match the engineering design.

Preserving Chemical Integrity

The primary function of high-vacuum processing is the preservation of the superalloy's complex surface chemistry.

Prevention of Atmospheric Contamination

Superalloys are highly reactive at elevated temperatures. A high-vacuum environment effectively prevents oxidation and nitridation, ensuring the material is not compromised by the surrounding atmosphere during heating.

Maintenance of Surface Composition

In addition to preventing oxide formation, vacuum processing prevents decarburization, a phenomenon where surface carbon is lost, weakening the material. This ensures that the chemical composition remains consistent from the core to the surface.

Active Surface Purification

The vacuum environment does more than protect; it actively cleans. The process has degassing and degreasing capabilities, removing surface scales and impurities to achieve a bright, purified surface finish essential for subsequent coating or bonding applications.

Precise Microstructural Control

Beyond surface protection, the high-vacuum furnace is the mechanism used to engineer the internal structure of the metal.

Regulation of the Gamma Prime Phase

Superalloys rely on the precipitation of the gamma prime ($\gamma'$) phase for their superior strength. Through specific multi-stage solution and aging processes, the furnace allows for the precise regulation of the size and volume fraction of this reinforcing phase.

Elimination of Compositional Segregation

Cast superalloys often suffer from compositional segregation (uneven distribution of elements) and dendritic structures. High-temperature vacuum treatment allows the material to reach super-solvus temperatures safely, dissolving these inhomogeneities into the matrix.

Homogenization of the Structure

By maintaining these specific high temperatures without oxidation, the furnace facilitates atomic-level diffusion. This results in a uniform single-phase austenite structure, which serves as the necessary foundation for consistent precipitation strengthening and reliable mechanical performance.

Operational Considerations and Trade-offs

While essential for quality, high-vacuum heat treatment involves specific operational variables that must be managed.

Thermal Efficiency vs. Complexity

Vacuum furnaces offer high thermal efficiency and permit rapid temperature rise and cooling, which is critical for locking in microstructures. However, achieving these rapid rates requires complex systems, often involving inert gas quenching, rather than simple radiative cooling.

Batch Processing Limitations

Unlike continuous atmospheric furnaces, vacuum furnaces are typically batch-processing units designed for high precision and repeatability. This prioritizes quality and consistency over high-volume throughput, making them ideal for high-value components rather than mass-commodity parts.

Making the Right Choice for Your Goal

To maximize the performance of superalloy components, align your processing parameters with your specific engineering objectives.

- If your primary focus is Maximum Tensile Strength: Prioritize multi-stage aging cycles that optimize the gamma prime volume fraction to pin dislocation movement.

- If your primary focus is Fatigue Life: Ensure the process reaches super-solvus temperatures to completely eliminate dendritic segregation and homogenize the grain structure.

- If your primary focus is Coating Adhesion: Leverage the furnace's degassing capabilities to ensure an ultra-clean surface for the bond coat and controlled Thermally Grown Oxide (TGO) formation.

The high-vacuum furnace is not merely a heater; it is a precision instrument that transforms a cast ingot into a high-performance engineering component.

Summary Table:

| Feature | Benefit for Superalloys | Impact on Performance |

|---|---|---|

| Atmospheric Removal | Prevents oxidation and nitridation | Maintains chemical integrity and surface purity |

| Microstructural Control | Regulates Gamma Prime ((\gamma')) phase | Enhances mechanical strength and creep resistance |

| Surface Purification | Active degassing and degreasing | Ensures superior coating adhesion and finish |

| Homogenization | Dissolves compositional segregation | Guarantees uniform mechanical properties throughout |

Elevate Your Superalloy Processing with KINTEK

Maximize the strength and fatigue life of your high-value components with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide Muffle, Tube, Rotary, Vacuum, and CVD systems tailored specifically for the rigorous demands of superalloy heat treatment. Whether you need precise multi-stage aging or rapid gas quenching, our customizable high-temp furnaces ensure consistent microstructural homogenization and ultra-clean surface finishes.

Ready to optimize your thermal cycles? Contact our engineering experts today to discover how KINTEK can transform your material performance.

Visual Guide

References

- A. Bezold, Steffen Neumeier. Segregation-induced strength anomalies in complex single-crystalline superalloys. DOI: 10.1038/s43246-024-00447-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What types of vacuum pumps are used in vacuum sintering furnaces? Optimize Your Sintering Process with the Right Pump System

- What are the benefits of vacuum sintering? Achieve Superior Material Properties and Purity

- Is vacuum brazing better than brazing? Unlock Superior Joint Quality for Critical Applications

- What are the advantages of a vacuum drying oven for photocatalyst powders? Preserve Nano-Structure and Purity

- How does argon help control aluminum volatilization in vacuum furnaces? Master Your Smelting Yields

- Why is a bell-shaped laser intensity distribution preferred for oxide crystal growth? Prevent Cracking and Stress

- What are the advantages of using a vacuum furnace? Achieve Superior Heat Treatment with Precision Control

- What is the typical lifespan of a vacuum furnace chiller? Extend It to 15+ Years with Proper Care